Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.1

Series ST Stopper cylinders

MOVEMENT >

CATALOGUE

>

Release 8.8

/2.25.01

1

MOVEMENT

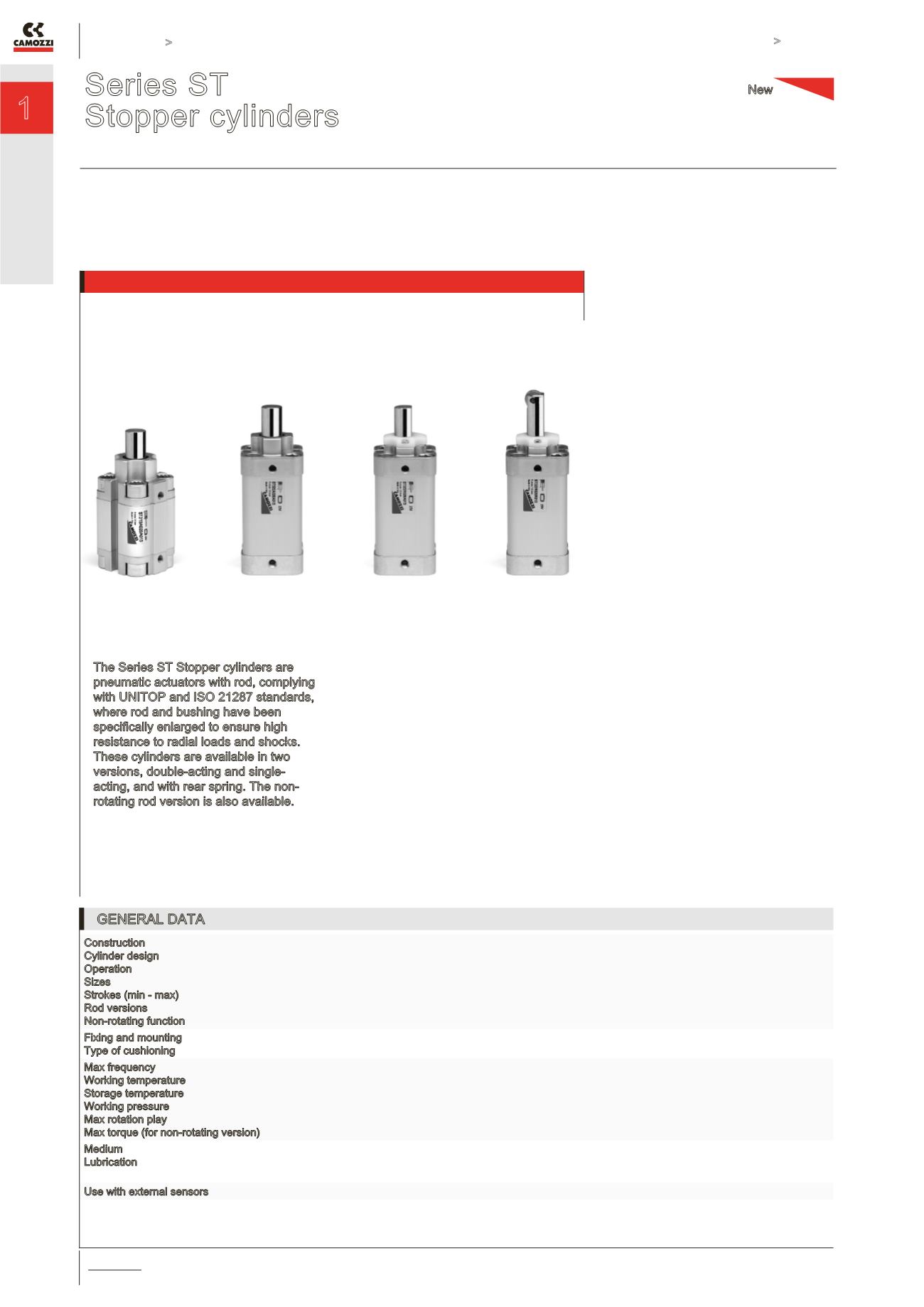

Series ST

Stopper cylinders

Single and double-acting, magnetic, non-rotating

Sizes 20, 32, 40, 50 mm

The Series ST Stopper cylinders are

pneumatic actuators with rod, complying

with UNITOP and ISO 21287 standards,

where rod and bushing have been

specifically enlarged to ensure high

resistance to radial loads and shocks.

These cylinders are available in two

versions, double-acting and single-

acting, and with rear spring. The non-

rotating rod version is also available.

The detection of the piston position is

enabled by means of proximity switches

(Mod. CST or CSH) which are mounted

in slots along three sides of the cylinder

profile. It is possible to cover the slots

with a proper profile (Mod. S-CST-500).

The high resistance to shocks and radial

loads and the easy mounting makes

Series ST particularly suitable for use

in transport/conveyor lines where it is

required to stop the transit of workpieces

and workpiece-holder pallets.

»

»

In compliance with UNITOP

and ISO 21287 standards

»

»

Compact design

»

»

Can be used with

magnetic sensors

»

»

Reliable and silent

»

»

Non-rotating rod version

»

»

Roller rod version

»

»

Female threaded rod version

»

»

High capacity to absorb

kinetic energy of

workpiece-holder pallets

»

»

Mechanical end-stroke

shock absorbers

GENERAL DATA

Construction

Cylinder design

Operation

Sizes

Strokes (min - max)

Rod versions

Non-rotating function

profile with self-tapping screws

compact based on UNITOP and ISO 21287 standards

double-acting, single-acting rear spring, double-acting rear spring

20, 32, 40 (Mod. ST32 only), 50 mm

5 ÷ 30 mm (see the table of standard strokes)

without thread, with female thread, non-rotating, non-rotating with feemale thread, non-rotating with roller

with technopolymer anti-friction ring

Fixing and mounting

Type of cushioning

direct with holes on the end-caps, in any position

mechanical end-stroke shock absorbers in rubber

Max frequency

Working temperature

Storage temperature

Working pressure

Max rotation play

Max torque (for non-rotating version)

5 Hz (Ø 20, 32, 40 mm) - 3 Hz (Ø 50 mm)

0°C ÷ 80°C (with dry air -20°C)

-20°C ÷ 100°C

1 ÷ 10 bar (double-acting) - 2 ÷ 10 bar (single-acting)

± 4° (Ø 20, 32 e 40 mm) - ± 3° (Ø 50 mm)

1.5 Nm (Ø 20 mm) - 2.5 Nm (Ø 32 e 40 mm) - 3.5 Nm (Ø 50 mm)

Medium

Lubrication

filtered air in class 7.8.4 according to ISO 8573-1 standard.

Not required. The cylinder is pre-lubricated. If lubricated air is used, it is recommended to use oil ISOVG32.

Once applied the lubrication should never be interrupted.

Use with external sensors

slots on the three sides for proximity switches Mod. CST and CSH

New