Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.Series 62 cylinders

CATALOGUE

1

/1.26.01

1

>

Release 8.8

MOVEMENT >

MOVEMENT

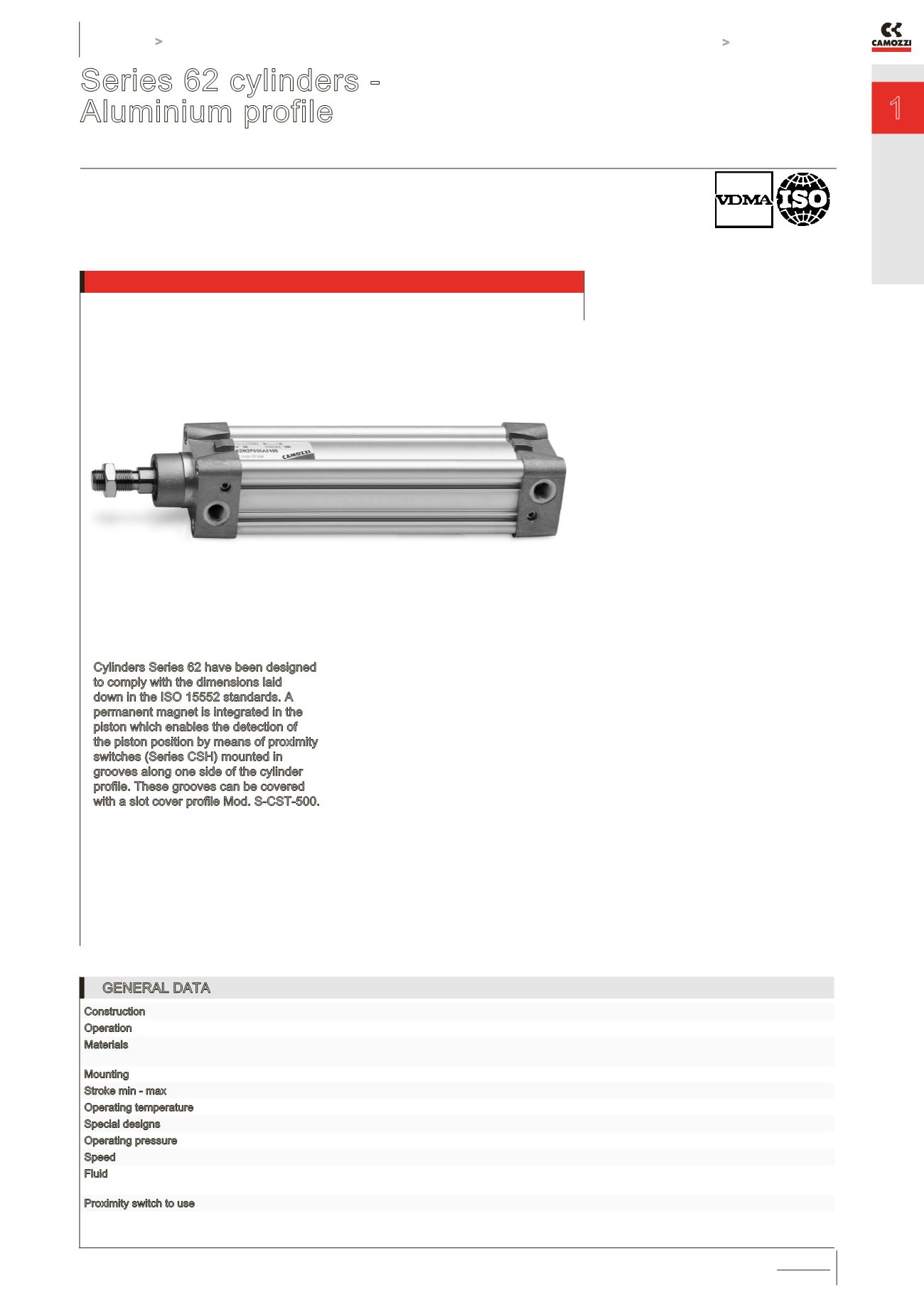

Series 62 cylinders -

Aluminium profile

Double-acting, magnetic, cushioned

ø 32, 40, 50, 63, 80, 100 mm

Cylinders Series 62 have been designed

to comply with the dimensions laid

down in the ISO 15552 standards. A

permanent magnet is integrated in the

piston which enables the detection of

the piston position by means of proximity

switches (Series CSH) mounted in

grooves along one side of the cylinder

profile. These grooves can be covered

with a slot cover profile Mod. S-CST-500.

These cylinders are equipped with

adjustable end-stroke cushioning. They

are also equipped with a mechanical

cushioning in order to reduce the impact

of the piston as it reaches the end of the

stroke.

»

»

In compliance with ISO

15552 standards and with

the previous DIN/ISO 6431/

VDMA 24562 standards

»

»

Rolled stainless steel rod

»

»

Clean and light design

»

»

Adjustable pneumatic

cushioning

GENERAL DATA

Construction

with tie-rods (inside the profile)

Operation

double-acting

Materials

AL end-blocks, technopolymer piston, rolled stainless steel AISI 420B piston rod, zinc-plated steel piston rod nut, anodized AL-

profile tube, zinc-plated steel tie-rods and nuts, NBR piston rod and piston seals, PU cushion seals (Ø 80-100: PU piston seal)

Mounting

with tie-rods, front flange, rear flange, feet front and rear trunnion, swivel combination

Stroke min - max

10 ÷ 2500 mm

Operating temperature 0°C ÷ 80°C (with dry air -10°C)

Special designs

see coding example

Operating pressure 1 ÷ 10 bar

Speed

10 ÷ 1000 mm/sec (NO LOAD)

Fluid

filtered air, without lubrication. If lubricated air is used, it is recommended to use oil ISOVG32. Once applied the lubrication should

never be interrupted.

Proximity switch to use CSH