Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.3

Series MX coalescing filters

TREATMENT >

CATALOGUE

>

Release 8.8

/1.10.01

3

TREATMENT

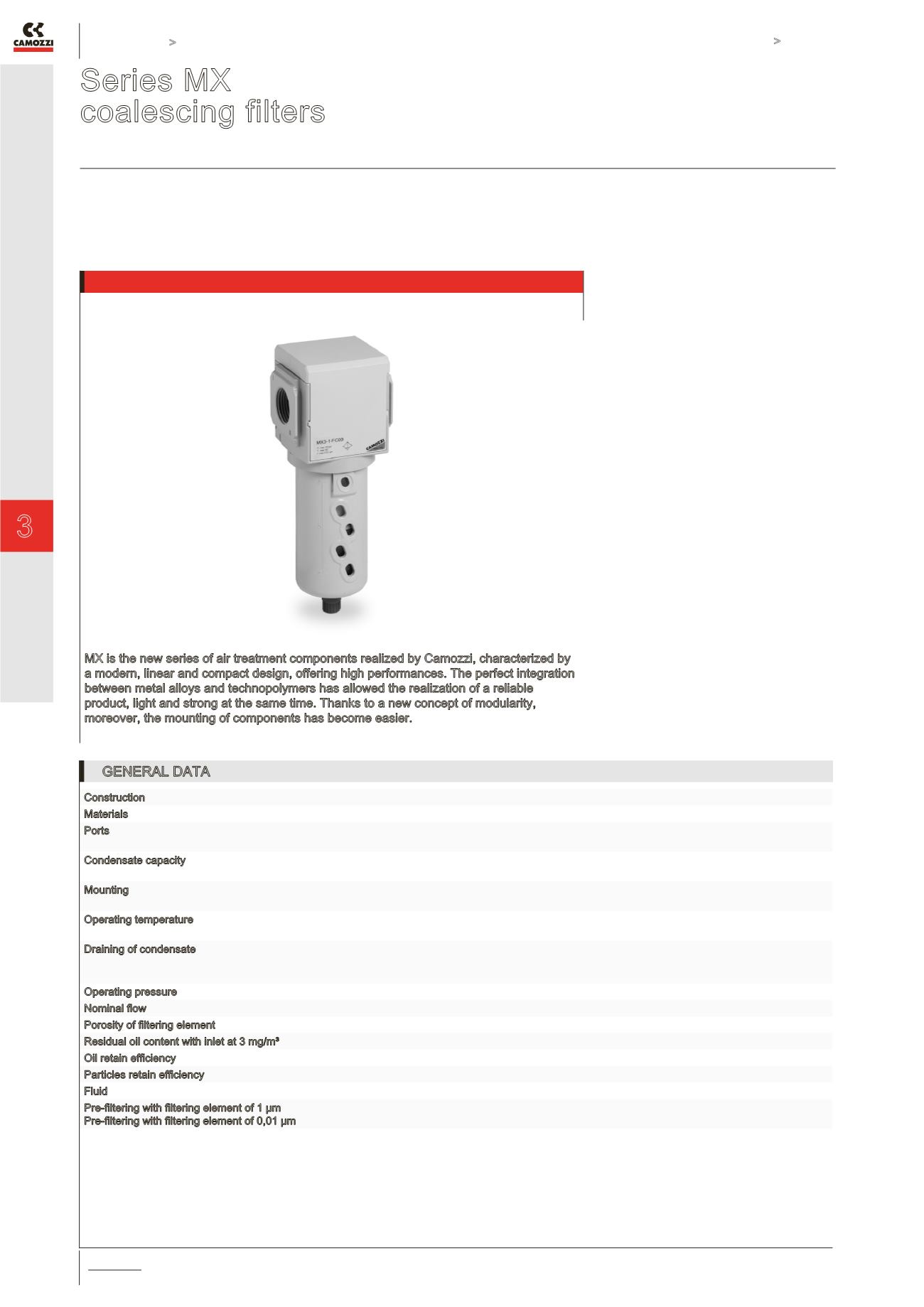

Series MX

coalescing filters

MX2 ports: G3/8, G1/2, G3/4 - MX3 ports: G3/4, G1

Modular

Bowl with technopolymer cover and bayonet-type mounting

MX is the new series of air treatment components realized by Camozzi, characterized by

a modern, linear and compact design, offering high performances. The perfect integration

between metal alloys and technopolymers has allowed the realization of a reliable

product, light and strong at the same time. Thanks to a new concept of modularity,

moreover, the mounting of components has become easier.

The Series MX has been realized to offer

a multi-sector solution that guarantees

saving in terms of installation time, space

and costs. A special configurator, available

on Camozzi website at

http://catalogue.camozzi.com (sec. Configurators), allows

the customer to choose the most suitable

solution for his application, selecting single

components or by configuring assembled

FRLs.

»

»

High performance and

compressed air purity

»

»

Air quality according to

ISO 8573-1 standard

»

»

Cartridge filters 1 or 0,01 μm

»

»

Manual, automatic or

depressing drain

»

»

Bowl locking system reducing

the risk of accidents

GENERAL DATA

Construction

modular, compact

Materials

see TABLE OF MATERIALS (pag. 3/1.10.02)

Ports

MX2: G3/8 - G1/2 - G3/4

MX3: G3/4 - G1

Condensate capacity

MX2: 55 cc

MX3: 85 cc

Mounting

vertical in-line

wall-mounting (by means of clamps)

Operating temperature

-5°C ÷ 50°C up to 16 bar (with the dew point of the fluid lower than 2°C at the min. working temperature)

-5°C ÷ 60°C up to 10 bar (with the dew point of the fluid lower than 2°C at the min. working temperature)

Draining of condensate

MX2: manual-semi automatic (standard), automatic, depressurization protected,

without drain with port G1/8

MX3: manual-semi automatic (standard), without drain with port G1/8

Operating pressure

0,3 ÷ 16 bar (with automatic drain 1,5 ÷ 12 bar)

Nominal flow

see FLOW DIAGRAMS (pag. 3/1.10.03)

Porosity of filtering element

0,01 μm 1 μm

Residual oil content with inlet at 3 mg/m³

< 0,01mg/m³ < 0,1mg/m³

Oil retain efficiency

99,80% 97%

Particles retain efficiency

99,99999% 99,999%

Fluid

compressed air

Pre-filtering with filtering element of 1 µm

Pre-filtering with filtering element of 0,01 µm

it is recommended to use a filter of 5 µm

it is recommended to use a filter with residual oil of 0,1 mg/m³