Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.Series 6E electromechanical cylinders

C_Electrics

1

15

>

2017

MOVEMENT >

MOVEMENT

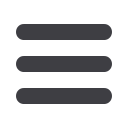

The analysis of the duty cycle and

of the pauses of the system is

essential to calculate the average

Fm axial loads and the number of

average revolutions nm that act on

the cylinder.

Normally, the duty cycle is composed

by phases and for each single

phase, we can have an acceleration,

constant speed or deceleration.

CALCULATION OF THE

AVERAGE AXIAL FORCE

CALCULATION OF THE AVERAGE

NUMBER OF REVOLUTIONS

The table shown below reports the

values of acceleration, speed and

deceleration for each phase.

F [N]

n [rpm]

time %

PHASE 1

Acceleration

Constant speed

Deceleration

Fa1

Fvc1

Fd1

na1

nvc1

nd1

ta1

tvc1

td1

PHASE 2

Acceleration

Constant speed

Deceleration

Fa2

Fvc2

Fd2

na2

nvc2

nd2

ta2

tvc2

td2

PHASE “n -1” Acceleration

Constant speed

Deceleration

Fan-1

Fvcn-1

Fdn-1

nan-1

nvcn-1

ndn-1

tan-1

tvcn-1

tdn-1

PHASE “n”

Acceleration

Constant speed

Deceleration

Fan

Fvcn

Fdn

nan-1

nvcn-1

ndn-1

tan-1

tvcn-1

tdn-1

TOTAL

100%

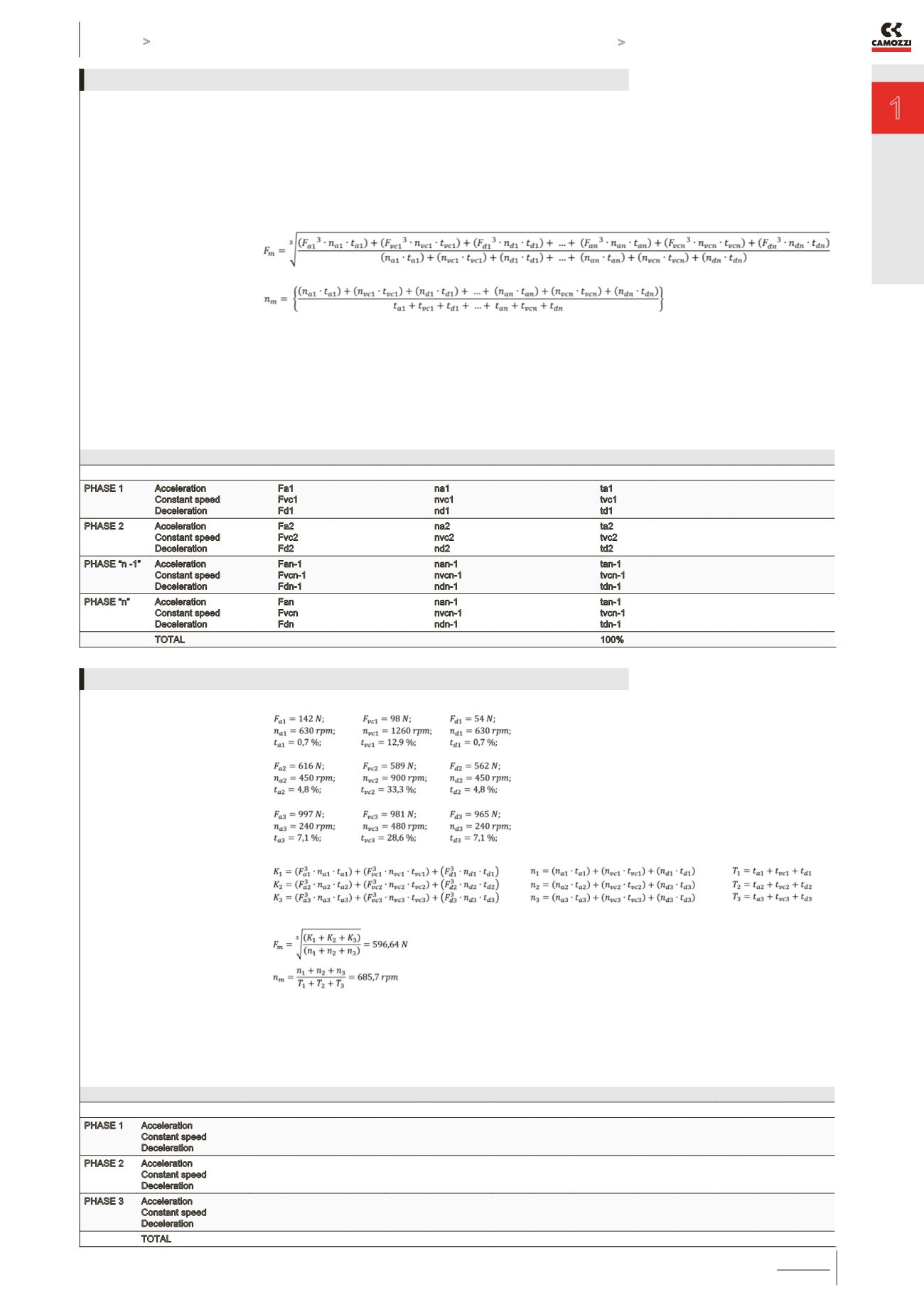

ANALYSIS OF THE DUTY CYCLE AND OF SYSTEM PAUSES

Phase 1

Phase 2

Phase 3

in this way it is possible to determine:

Concluding, we know that:

F [N]

n [rpm]

time %

PHASE 1 Acceleration

Constant speed

Deceleration

142

98

54

630

1260

630

0.7

12.9

0.7

PHASE 2 Acceleration

Constant speed

Deceleration

616

589

562

450

900

450

4.8

33.3

4.8

PHASE 3 Acceleration

Constant speed

Deceleration

997

981

965

240

480

240

7.1

28.6

7.1

TOTAL

100.0

APPLICATION EXAMPLE