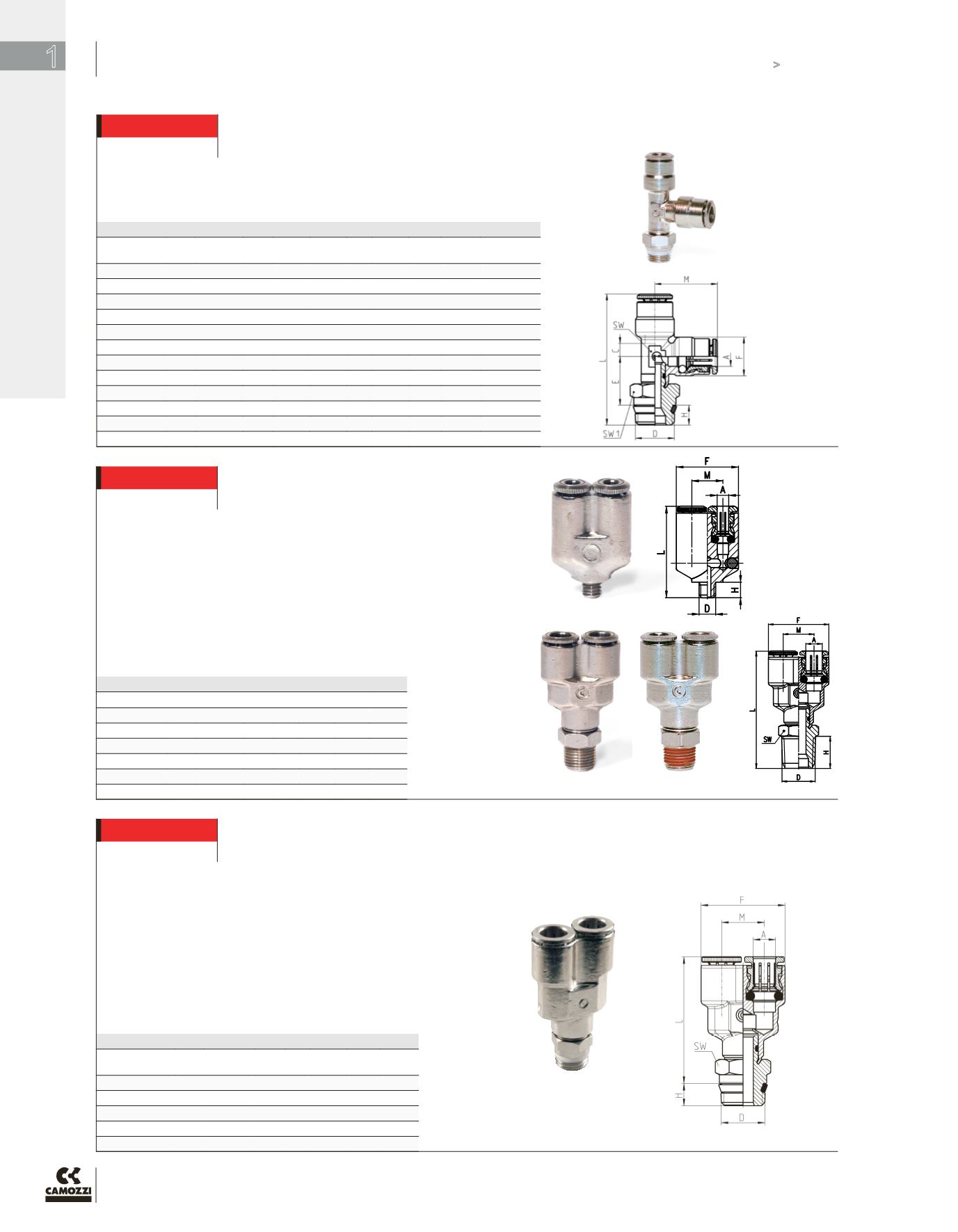

Fittings Mod. 6700...

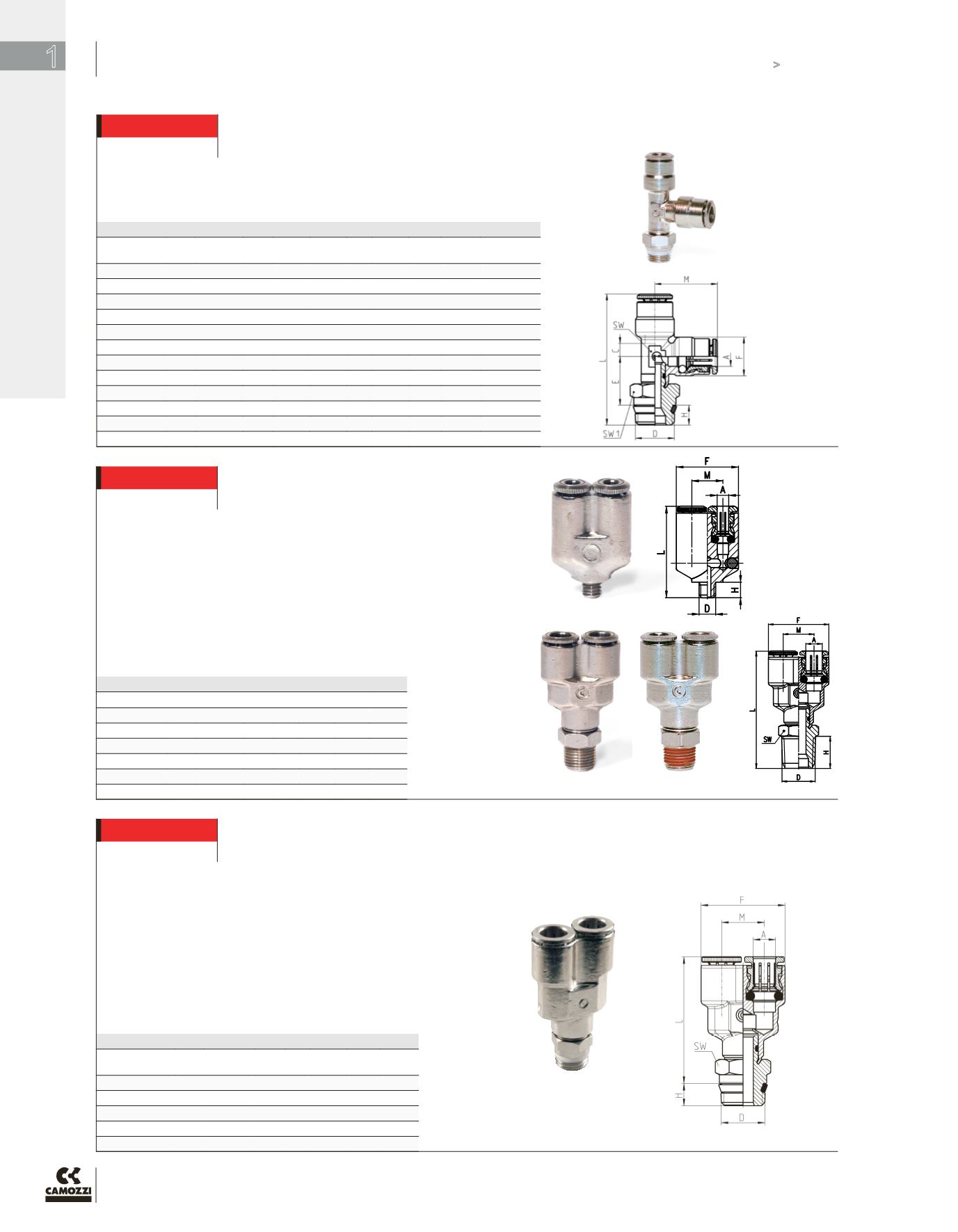

Fittings Mod. 6800...

DIMENSIONS

Insertion Force

Mod.

OD A F

G

L

S

H

B

Kg.

Min

Kg.

Max D

H2

DE

6700 02-00

1/8

0.339 0.346 0.571 0.343 0.433 0.138 314

439

0.347 0.122 0.551

6700 53-00

5/32 0.339 0.346 0.571 0.343 0.433 0.138 314

439

0.347 0.122 0.551

6700 04-00

1/4

0.465 0.472 0.669 0.468 0.473 0.158 314

533

0.473 0.142 0.669

6700 05-00

5/16 0.543 0.551 0.709 0.549 0.551 0.236 345

471

0.551 0.122 0.748

6700 06-00

3/8

0.622 0.630 0.807 0.625 0.650 0.315 439

485

0.630 0.122 0.827

6700 08-00

1/2

0.740 0.748 0.776 0.746 0.689 0.413 430

520

0.748 0.122 0.945

DIMENSIONS

Mod.

OD

A

G

C

F

L

T

6800 02-04

1/8

1/4 0.610 0.354 1.161 0.709

6800 53-04

5/32

1/4 0.610 0.354 1.161 0.709

6800 04-06

1/4

3/8 0.819 0.500 1.457 0.906

6800 04-08

1/4

1/2 0.681 0.504 1.319 0.945

6800 06-08

3/8

1/2 0.787 0.650 1.575 0.945

Cartridge

*

Hole tolerances: +0.002-0.000 [in.]

*

For plastic [non-metal] manifolds, reduce all hole dimensions “S” by 0.02 mm [0.001 in.]

*

INSTALLATION: Drill or bore hole per specifications per size of cartridge (dimensions H and S).

*

Smooth or ream hole dimensions to hole tolerances.

*

Simply press fit cartridge into hole with an evenly distributed force over the top surface.

*

Removal of the collet ring is not necessary.

*

Cartridge fittings are useful for installations in various manifolds and/or distribution blocks

when drilling and tapping are not desirable.

Reducer

NOTE: The Dimension ‘H2’ for the press-tool should be noted and followed, which creates a

specific mechanical stop. This serves the purpose of avoiding, (in case of any excessive insertion

force used), damage to the collet body, shape or design. Without which, could lead to some dam-

age or distortion of the collet bite/release ring.

All Dimensions in millimeters. Surface Finish of the gland seat required : Ra </= 0.8 microns.

**

Final Fit and Finish requires that the top most ridge/bite-ring of the cartridge body be at least

1

mm below the surface of the gland chamfer.

Gland Width “S” Tolerances **

+ .002’’ / - .000’’ Metal Seat Tolerance

+ .001’’ / - .001” Plastic Seat Tolerance

0.5

x 45

°

Chamfer Required

For the Ø3 Cartridge, Chamfer 0.3 x 45

°

Insertion Force - KG

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

22

F I T T I N G S

1

N I C K E L - P L A T E D B R A S S P USH - I N F I T T I NGS