Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.1

Series CGPT self-centering parallel grippers with T-guide

MOVEMENT >

CATALOGUE

>

Release 8.8

/7.17.01

1

MOVEMENT

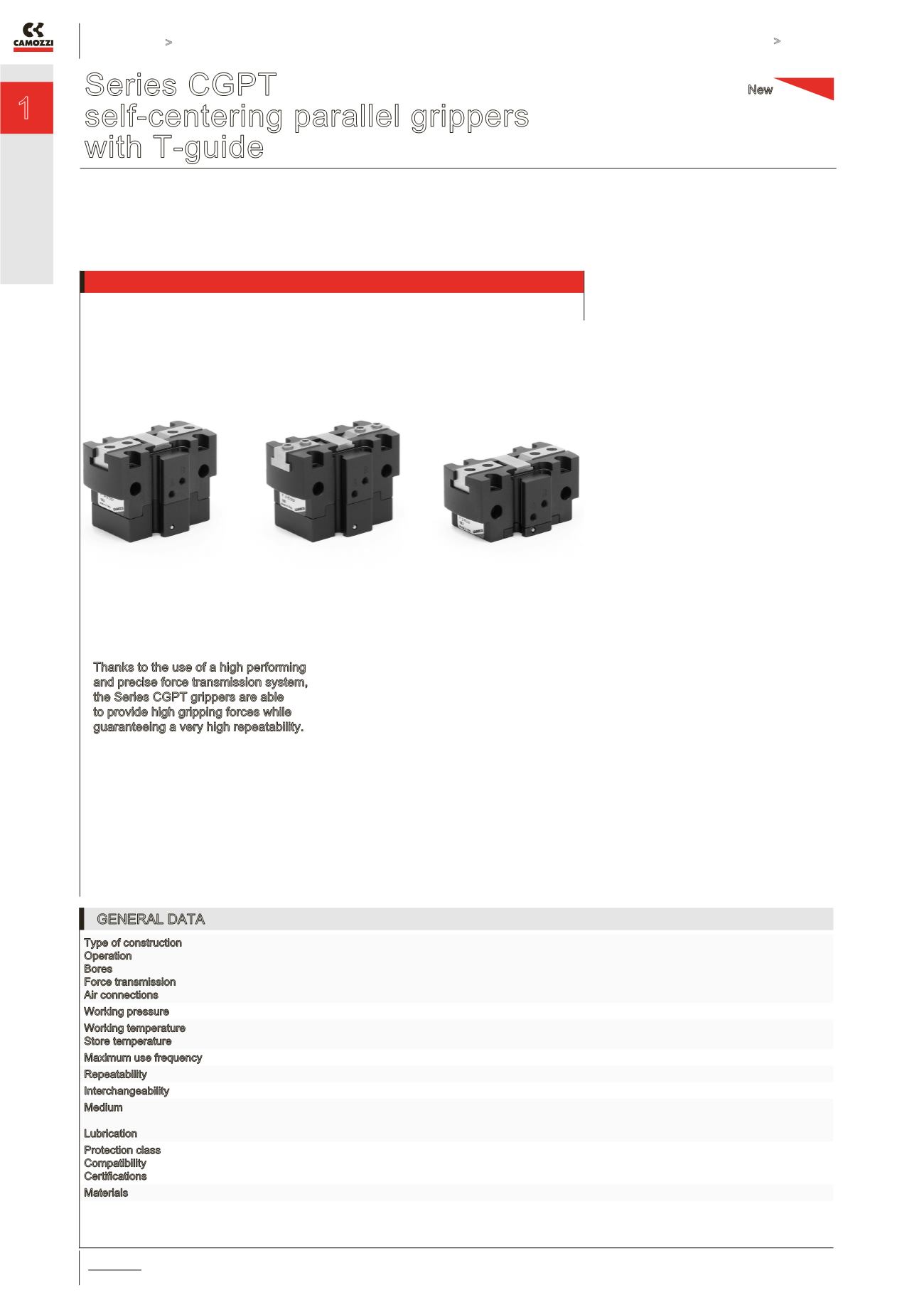

Series CGPT

self-centering parallel grippers

with T-guide

Single and double acting, magnetic, self-centering

Bores: ø 16, 20, 25, 32, 40 mm

Thanks to the use of a high performing

and precise force transmission system,

the Series CGPT grippers are able

to provide high gripping forces while

guaranteeing a very high repeatability.

The wide range of sizes available

allows you to find the best solution for

any need of movement. The grippers

are supplied with centering bushes

(tolerance H8) which, once positioned on

the body and/or on the jaws, are able to

guarantee, during maintenance, a high

interchangeability of the gripper and of

the extensions.

»

»

Robust, compact

and light design

»

»

High closing/opening forces

»

»

Fixing from the top, from

below and from the side

»

»

Supply on the side or

on the bottom (even

without using tubes)

»

»

Self-centering jaws

»

»

High closing and

opening repeatability

»

»

High interchangeability

(centering bushes)

»

»

Position detection thanks

to the use of magnetic

proximity switches.

»

»

In compliance with

ROHS directive

»

»

PTFE, Silicone and

Copper free

»

»

High reliability

»

»

High resistance to external

loads thanks to the T-guide

»

»

Variants available for

use in ATEX zones and

for high temperatures

GENERAL DATA

Type of construction

Operation

Bores

Force transmission

Air connections

Self-centering parallel gripper with T-guide

Single acting (NO, NC), double acting

Ø16, 20, 25, 32, 40 mm

Lever

M3 (Ø16), M5 (Ø20, 25, 32), G1/8 (Ø40)

Working pressure

2 ÷ 8 bar (double acting), 4 ÷ 8 bar (single acting)

Working temperature

Store temperature

5°C ÷ 60°C (standard) - 5°C ÷ 150°C (high temperature version)

-10°C ÷ 80°C

Maximum use frequency 3 Hz (ø 16, 20, 25, 32), 2 Hz (ø 40)

Repeatability

0.02 mm

Interchangeability

0.1 mm

Medium

Lubrication

Filtered air in class 7.4.4 according to ISO 8573-1. In case lubricated air is used, we recommend ISOVG32 oil and to never

interrupt lubrication.

After 10 million cycles, grease the sliding zones using Molykote DX grease.

Protection class

Compatibility

Certifications

IP 40

ROHS Directive

ATEX (II 2GD c IIC 120°C(T4)-20°C≤Ta≤80)

Materials

PTFE, Silicone and Copper free

N.B. Pressurize the pneumatic system gradually in order to avoid uncontrolled movements

New