Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.Series CST-CSV-CSH-CSB-CSC-CSD sensors

CATALOGUE

1

/9.05.17

1

>

Release 8.8

MOVEMENT >

MOVEMENT

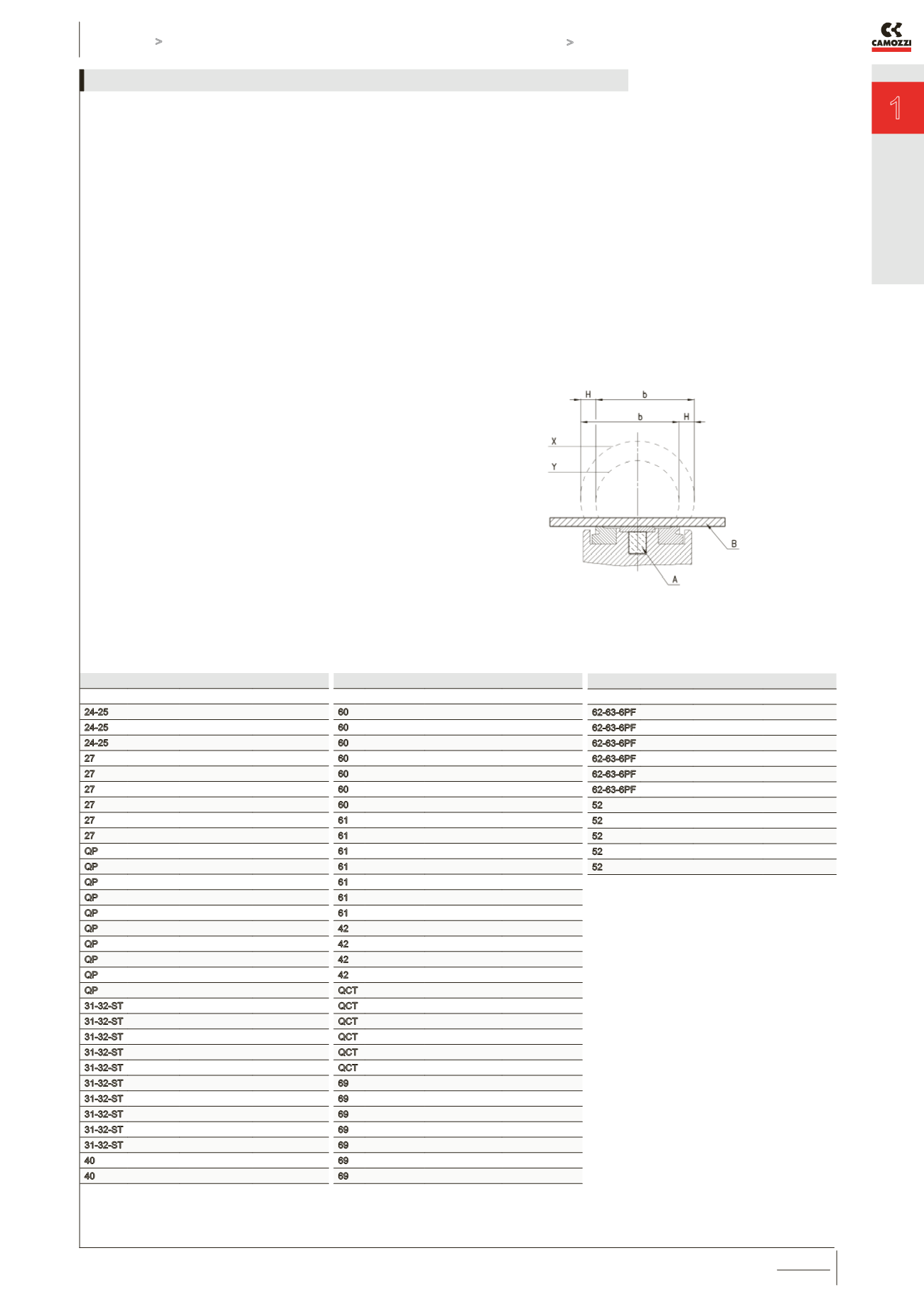

CONTACT STROKE AND HYSTERESIS - correct use of magnetic sensors

The magnetic sensors consist of a reed switch which is contained in a glass bulb

filled with a rarefied gas. The switches (or contacts) that are made of magnetic

material (nickel-iron) are flexible and are coated, at the contact points, with high

quality non-arcing materials. Switching is effected by means of a suitable magnetic

field and actuation is achieved by means of the permanent magnet

inside the piston.

NOTE: THE PRESENCE OF IRON MASSES NEAR THE CYLINDER OR THE

GRIPPERS (LIKE IRON SCREWS AND FIXING PLATES) CAN CHANGE THE

DIRECTION AND THE POWER OF THE MAGNETIC FIELD.

The Reed sensors are Normally Open, therefore, when subjected to the effect of the

magnetic field, close the circuit.

Series

Ø

b ( mm )

H ( mm )

24-25

16

9.2

1.2

24-25

20

12

1

24-25

25

11.7

1.1

27

20

10.5

1.6

27

25

10.9

1.6

27

32

10.7

1.1

27

40

12.1

1.7

27

50

12.1

1.2

27

63

14.1

1.3

QP

12

10

1.3

QP

16

11.8

1.5

QP

20

11.1

1.6

QP

25

10.6

1.6

QP

32

12.7

1.2

QP

40

12.5

1.1

QP

50

15.4

1.6

QP

63

16.7

1.5

QP

80

13.2

1.7

QP

100

16.8

1.8

31-32-ST 12

9.2

1.4

31-32-ST 16

7.9

1.3

31-32-ST 20

9.1

1.5

31-32-ST 25

10.6

1.5

31-32-ST 32

11.9

1.7

31-32-ST 40

12.9

2.2

31-32-ST 50

14.7

1.2

31-32-ST 63

15.2

1.4

31-32-ST 80

16.6

1.8

31-32-ST 100

16,8

1,7

40

160

24

2

40

200

26

2

Series

Ø

b ( mm )

H ( mm )

60

32

9.9

1

60

40

8.9

1.2

60

50

10.7

1

60

63

12.9

1.2

60

80

11.5

1.4

60

100

14.9

1.4

60

125

22

1

61

32

9

1

61

40

9.3

1.3

61

50

11

1.6

61

63

13.4

1.3

61

80

13.2

1.6

61

100

15.2

1.7

61

125

22.1

1.3

42

32

10.8

1.5

42

40

11.2

1.6

42

50

12.6

1.7

42

63

14.1

1.7

QCT

20

10

1.7

QCT

25

11.4

1.8

QCT

32

12.1

1.8

QCT

40

12.4

1.8

QCT

50

13.7

1.9

QCT

63

13.5

1.8

69

32

34.5

3.8

69

40

29.6

4.1

69

50

31.5

4.6

69

63

32.3

3.1

69

80

24

2.9

69

100

25.6

2.9

69

125

30.1

1.7

Series

Ø

b ( mm )

H ( mm )

62-63-6PF 32

10

1

62-63-6PF 40

11

1

62-63-6PF 50

12

1.2

62-63-6PF 63

13

1

62-63-6PF 80

13

1

62-63-6PF 100

16

1

52

25

19.3

1.8

52

32

27.9

1.6

52

40

26

2.3

52

50

39.9

2.9

52

63

40.7

4.2

OPERATING FIELD OF SENSORS

WITH RESPECT TO THE MAGNETIC PISTON (below picture)

The maximum speed (in m/second) for a cylinder guided by magnetic sensors is given

by b/t = speed where:

b = contact stroke in mm (see the table) - this value indicates the amplitude of

the magnetic field or switching field when the circuit is closed.

t = total reaction time in milliseconds of the electric control components

connected downstream of the sensor

H = operational hysteresis of the sensor with respect to the shape and amplitude

of the magnetic field.

A = magnet

B = actuator

X =

Y =

The operating field, as a result of hysteresis, is displaced by the value H in the

opposite direction to movement of the cylinder. The maximum speed permitted for

each cylinder depends on value b and on reaction time of the different components

connected downstream of the sensor.