CATALOGUE >

Release 8.7

APPENDIX >

Camozzi products

Information for the use of Camozzi products

a

APPENDIX

Just browsing through the pages of our website

www.camozzi.com,you will have the possibility to

download GSD files for the configuration of Valve

Islands, all relative use and installation manuals

and the configuration software of the product codes.

Moreover, here you can find all 2D and 3D files

in the most commonly used formats.

Air treatment

Filtering

The temperature affects the capacity of air to maintain water particles

(relative humidity).

Warm air contains a larger quantity of water than the same volume

filled with cold air.

An excess of humidity causes the formation of condensate.

Cooling of the air modifies the structure of the water it contains,

by turning it from a gaseous to a liquid state.

Specific apparatus can be used to cool (refrigerator) and heat (drier)

the air and are, as a rule, assembled on the outlet of the compressor.

The filtering elements mounted inside the filters for compressed air,

are only partly able to separate the condensate from the air, in fact,

their main function is to eliminate any solid particles.

During the production of compressed air, compressors can introduce

oil into the distribution network. The characteristics of this oil are not

compatible with the seals of pneumatic components.

The market trend towards miniaturized products imposes the

requirement to use coalescing filters.

It is advisable to provide for automatic drains on the filters.

Lubrication

This is not necessary as the components are already greased with

special products. Only use oils with a viscosity of 32 cSt at 40°C.

The oil quantity has to be a maximum of 1 drop per minute, this

regulation has to be made with the machine in normal operation.

The lubrication, once applied, must never be interrupted. If not,

the seals of the components could degenerate, compromising their

function.

For a correct use of our products, refer to the values shown in the

table of the Air Quality classes according to the Standard DIN ISO

8573-1.

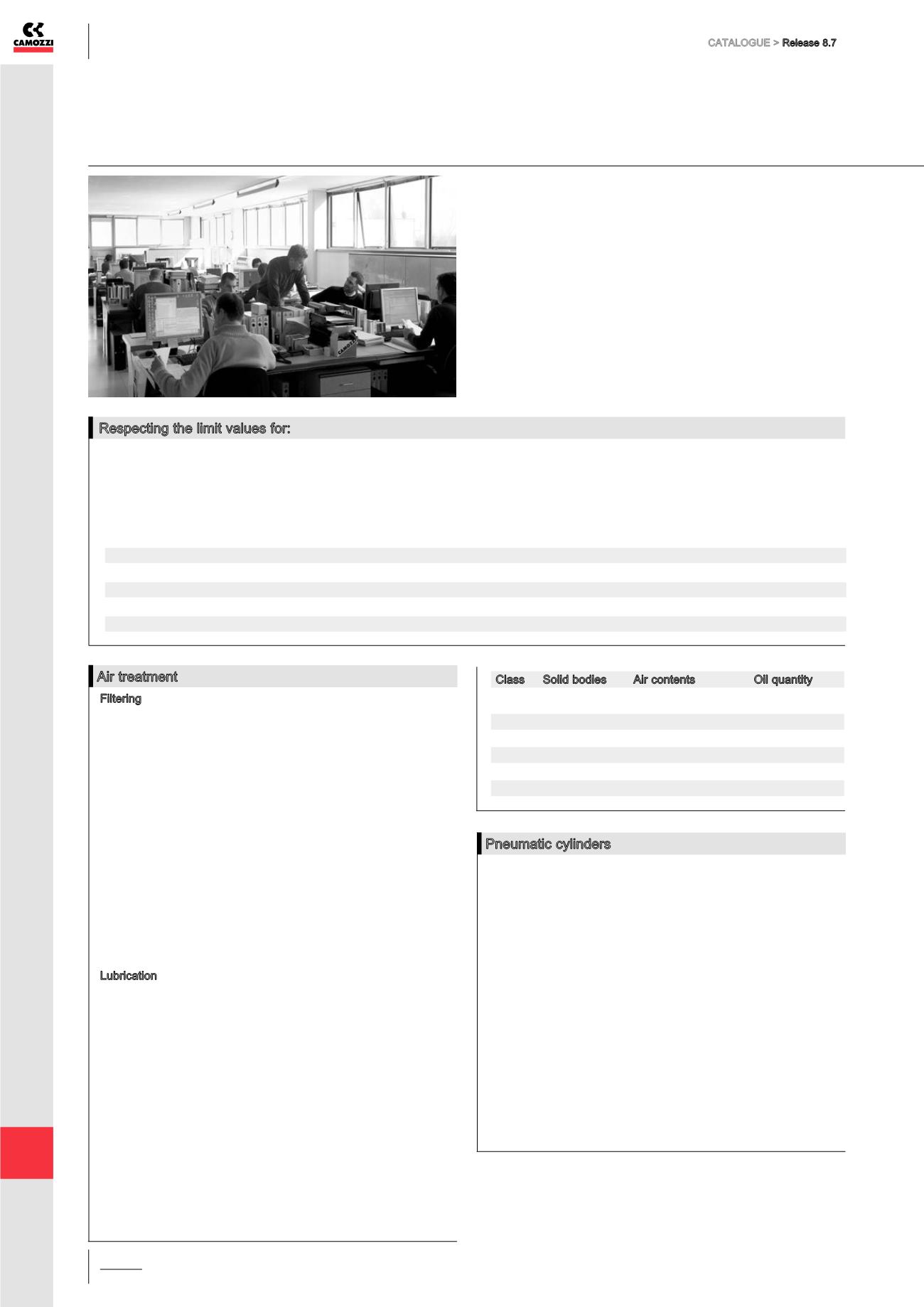

Class Solid bodies Air contents

Oil quantity

Max. dimension dew-point

Max

of the particles

concentration

1

0,1 µ

-70 °C

0,01 mg/m

3

2

1 µ

-40 °C

0,1 mg/m

3

3

5 µ

-20 °C

1 mg/m

3

4

15 µ

+3 °C

5 mg/m

3

5

40 µ

+7 °C

25 mg/m

3

Pneumatic cylinders

The choice of the correct cylinder mounting to the structure

and also that of the rod attachment to any moving parts, are as

important as the control of parameters relating to speed, mass and

radial loads. The control of these parameters has to be guaranteed

by the user. The location of position sensors (reed switches),

and their switching response times to magnetic fields, is dependant

upon the type and bore size of cylinder and the appropriate

precautions need to be taken when fixing these items.

(see notes on the pages relative to the sensors).

We do not advise the use of a cylinder application as a shock

absorber or as pneumatic cushioning. If used at the maximum

speed, we recommend gradual deceleration to avoid a violent impact

between piston and the cylinder end cover.

As a general value, we calculate a maximum average speed of

1 m/sec. In this case no lubrication is required as the lubrication

introduced during assembly is sufficient to guarantee good operation.

If faster speeds are required, we suggest lubrication in the

quantities described above.

Respecting the limit values for:

• Pressure

• Speed

• Mass

• Voltage

• Actuating force

• Temperature

The pneumatic components have to be used with properly prepared compressed air. The type of preparation depends on the environmental

characteristics and the sector of industry in which they will be used. Except for different imformation shown on the technical data sheet for the

single products, in general the air characteristics should be:

Fluid temperature:

-10 ÷ +60°

Environmental temperature:

-20 ÷ +80°

Air filtering according to DIN ISO 8573-1:

not superior to the classes 5/5/4 (see table)

Lubrication:

not necessary, in case use ISOVG32 oil and do not interrupt the lubrication once applied.

Oil contents:

From 1 to 5 drops every 1000 litres of air

a

/2.01

01