CATALOGUE >

Release 8.8

APPENDIX >

Camozzi products

a

APPENDIX

a

/2.01

Information for the use of Camozzi products

In order to guarantee a proper functioning of its products, Camozzi S.p.A. herewith provides some general information.

Air quality

Beyond respecting the limit values as pressure, force, speed, voltage,

temperature and others values that are indicated in the general tables

of each product, another aspect to consider is the quality of the

compressed air. While resources as electricity, water and gas are

normally supplied by external companies that guarantee the standard,

air is produced inside a company and therefore it’s the user that has

to guarantee its quality.

This characteristic is essential for a proper functioning of pneumatic

systems. One m³ of air at the atmospheric pressure contains various

substances:

- more than 150 million of solid particles with dimensions

from 0,01 µm to 100 µm,

- fumes due to combustion,

- water vapour, which quantity depends from the temperature,

at 30° there are about 30 g/m³ of water

- oil, up to about 0,03 mg

- micro organisms

- as well as different chemical contaminants, odours etc …

Compressing the air, in the same volume of 1 m³, we find “n” m³

of air, therefore the substances indicated before increase.

In order to limit this, at the inlet and outlet of the compressors filters,

driers and oil separators are installed.

In spite of these precautions, the air, during its transport inside tubes

or storage in tanks, can collect flakes of rust, a part of the water

vapour contained in the air, cooling down, can pass from a gaseous

state into a liquid state, but can also transform the oil fumes

that were not retained by the previous filters.

For this reason it is advisable to equip the systems or machinery

with air treatment groups.

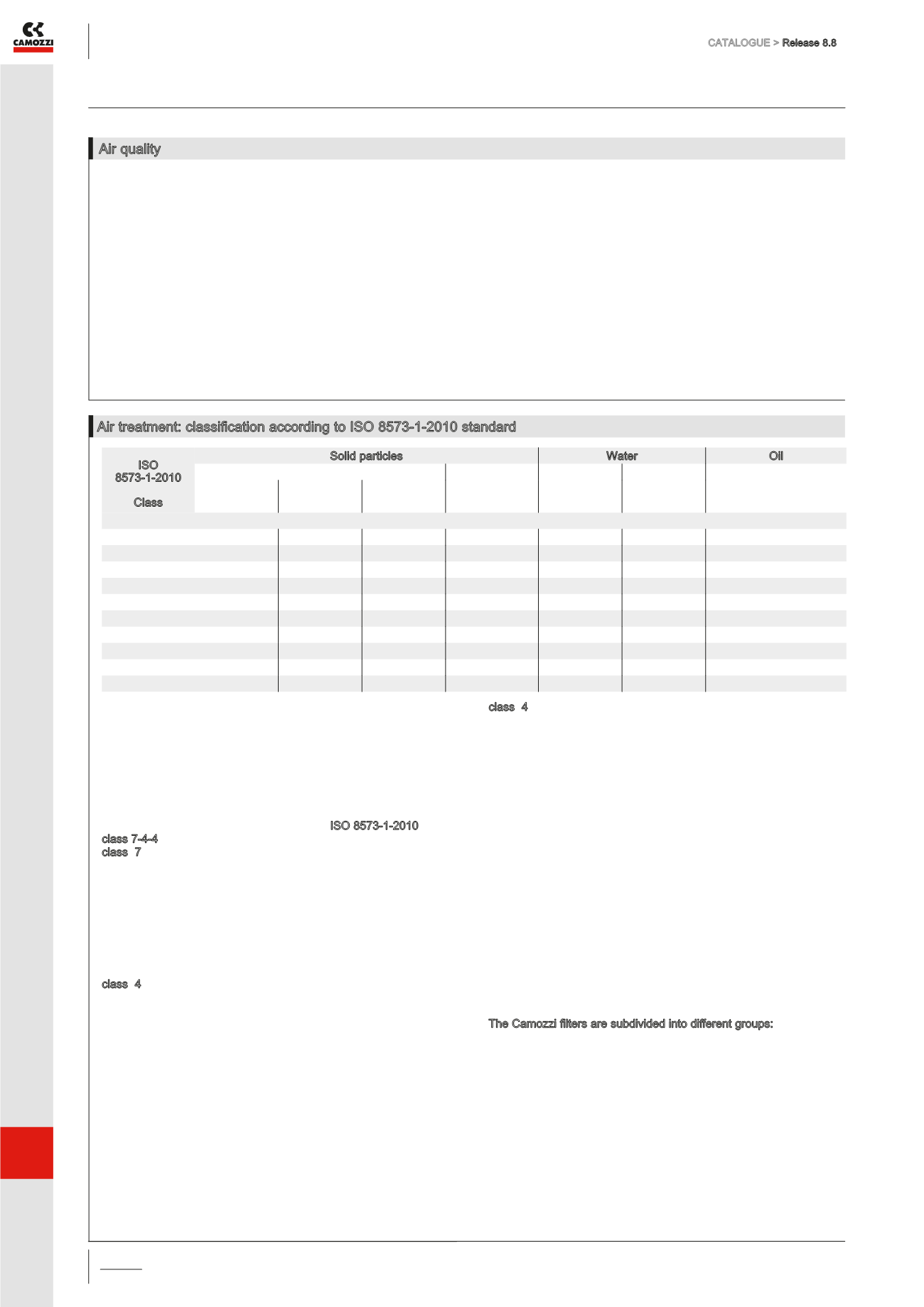

Air treatment: classification according to ISO 8573-1-2010 standard

These groups can have different functions: isolation valves,

pressure regulators, soft-start valves and of course filters.

Only in some applications, lubricators are still used.

Regarding filtering, there are standards of reference

as ISO 8573-1-2010 that classify air according to its quality.

This standard defines the relevant class of compressed air according

to the presence of three contaminating categories: solid parts,

water or water vapour, concentration of micro mist or oil vapours.

In general, if not specified otherwise in the characteristics of the single

component, the Camozzi products require an ISO 8573-1-2010

class 7-4-4 air quality, this wording indicates that:

class 7

A maximum concentration of solid particles of 5 mg/m³ is allowed

and the dimension is not declared.

The standard Camozzi filters are declared as class 7 even if the

filtering elements are realized with a technology that enables to

separate solid particles with a dimension of more than 25 µm.

The air exiting from our filters and therefore the air at the inlet of

all other components can contain solid particles with a maximum

concentration of 5 mg/m³ but with a maximum dimension of 25 µm.

class 4

The temperature has to arrive at ≤ 3° in order for the water vapor

to condense and become liquid.

The classical filters have characteristics that separate the humidity

in the air only if it is in a liquid state or nearly.

It is the cooling of the air that enables condensation and then

the elimination of the water present in the form of water vapour.

The air flow entering the bowl of the filter sustains a minimum

expansion phase, (according to the gas law when gas sustains

a sudden expansion its temperature lowers) followed by a vortex,

this enables the heavier particles and the water vapour,

that is condensed due to the expansion, to adhere to the sides

of the bowl and slide down towards the drainage system.

Except for specific versions, the Camozzi filters are declared

to be in class 8.

This means that the user has to provide in installing driers in its

compressed air production system that, by cooling the air, dehumidify it.

class 4

The concentration of oily parts must be of maximum 5 mg/m³.

The compressors use oil that during the process can be introduced

into the system in the form of aerosol, vapour or liquid.

This oil, as all other pollutants, is transported by the air into the

pneumatic circuit, enters in contact with the seals of the components

and subsequently in the environment through the outlets of the

solenoid valves. In this case coalescing filters are used that have an

operating principle and filtering cartridges that are different compared

to others and this allows to aggregate those micro-molecules of oil

suspended in the air and remove them.

The Camozzi coalescing filters enable to reach classes 2 and 1.

It is important to keep in mind that the best performance is reached

only by means of a filtering process with subsequent phases.

As illustrated, there are filters with different characteristics,

a very efficient filter for a certain contaminant, but may not be so

for other contaminants.

The filtering elements determine the class of the filters,

these elements should be replaced after a certain period or after

a certain number of working hours.

These parameters vary according to the characteristics

of the incoming air.

The Camozzi filters are subdivided into different groups:

- Filtering element of 25 µm, class 7-8-4

- Filtering element of 5 µm, class 6-8-4

- Filtering element of 1 µm, class 2-8-2

with pre-filter class 6-8-4

- Filtering element of 0,01 µm, class 1-8-1

with pre-filter class 6-8-4 residual oil content of 0,01 mg/m³

- Activated carbon, class 1-7-1

with pre-filter class 1-8-1 residual oil content of 0,003 mg/m³

The components are previously greased with special products and do

not need an additional lubrication. In case it should be necessary,

use ISO VG 32 oil.

The quantity of oil introduced into the circuit depends on the different

applications, we suggest a dosage of max. 3 drops per minute.

ISO

8573-1-2010

Class

Solid particles

Water

Oil

Max. Number of Particles per m³

Max

Concentration

mg/m³

Water pressure

dew point

°C

Liquid

g/m³

Total content

(liquid, aerosol and vapour)

mg/m³

0,1 - 0,5

µm

0,5 - 1

µm

1 - 5

µm

0

More strict than class 1, defined by the device user

1

≤ 20,000

≤ 400

≤ 10

-

≤ - 70°

-

≤ 0,01

2

≤ 400,000

≤ 6,000

≤ 100

-

≤ - 40°

-

≤ 0,1

3

-

≤ 90,000

≤ 1,000

-

≤ - 20°

-

≤ 1

4

-

-

≤ 10,000

-

≤ + 3°

-

≤ 5

5

-

-

≤ 100,000

-

≤ + 7°

-

-

6

-

-

-

≤ 5

≤ + 10°

-

-

7

-

-

-

5 - 10

-

≤ 0,5

-

8

-

-

-

-

-

0,5 - 5

-

9

-

-

-

-

-

5 - 10

-

X

-

-

-

> 10

-

> 10

-