Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.Series 52 cylinders

CATALOGUE

1

/8.10.03

1

>

Release 8.8

MOVEMENT >

MOVEMENT

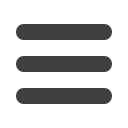

COMPLEX LOADS

If more than one force and torque is

applied simultaneously, they have

to be calculated according to the

following formula: L/L (max)+ Ls/Ls

(max)+ M/M (max)+ Ms/Ms (max)+

Mv/Mv (max ) ≤1.

For models 52M, the load and torque

values refer to the center of the tube.

For models 52G/52R the load and

torque values refer to the center

point of the external guide. It is

also necessary for these models to

guarantee on the fixing surface a max

0.1 flatness’s value.

The load and torque values

refer to a velocity of: Models

52M/52G/52M/52G ≤ 0,2 m/s, models

52R ≤ 2 m/s.

For the adjustment coefficients of

loads see page 1.8.10.04

Table showing the maximum permitted loads and torque forces

Mod.

L Max ( N )

Ls Max ( N )

M Max ( Nm )

Ms Max ( Nm )

Mv Max ( Nm )

Mass at 0 mm stroke (kg)

Additional mass per 100 mm (kg)

52M2P25A - 52M8P25A 270

-

13

2,5

11

0,88

0,30

52M2C25A - 52M8C25A 270

-

8

2

7

0,62

0,30

52G2P25A - 52G8P25A 580

580

23

10

23

1,31

0,30

52G2C25A - 52G8C25A 340

340

9

5

9

0,88

0,30

52R2P25A - 52R8P25A

850

1300

65

35

105

1,97

0,42

52R2C25A - 52R8C25A 850

1300

29

35

64

1,33

0,42

52M2P32A - 52M8P32A 300

-

30

3

24

1,40

0,39

52M2C32A - 52M8C32A 300

-

15

3

12

0,96

0,39

52G2P32A - 52G8P32A 850

850

33

15

33

2,09

0,39

52G2C32A - 52G8C32A 460

460

14

6,5

14

1,35

0,39

52R2P32A - 52R8P32A

900

1500

79

40

125

2,96

0,48

52R2C32A - 52R8C32A 900

1500

36

40

76

1,91

0,48

LOADS AND TORQUE FORCES Ø 25 - 32

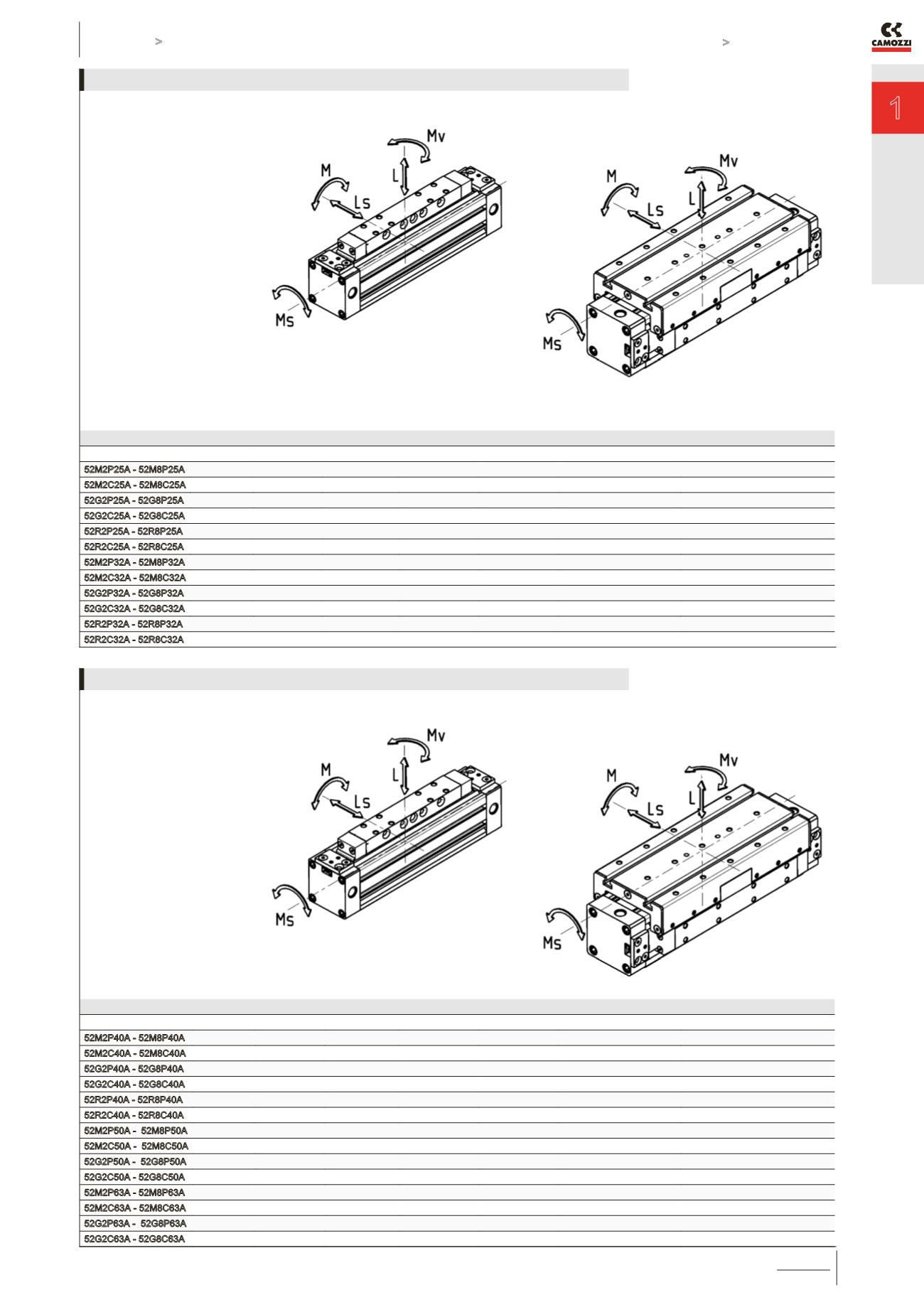

COMPLEX LOADS

If more than one force and torque is

applied simultaneously, they have

to be calculated according to the

following formula: L/L (max)+ Ls/Ls

(max)+ M/M (max)+ Ms/Ms (max)+

Mv/Mv (max ) ≤1.

For models 52M, the load and torque

values refer to the center of the tube.

For models 52G/52R the load and

torque values refer to the center point

of the guide.

The load and torque values refer

to a velocity of: Models 52M/52G

≤0,2 m/s

Models 52R ≤2 m/s

If the velocity exceeds 0.2m/s for

the models 52M/52G, the load and

torque values have to be multiplied

by the coefficients according to the

table.

For the adjustment coefficients of

loads see page 1.8.10.04

Table showing the maximum permitted loads and torque forces

Mod.

L Max ( N )

Ls Max ( N )

M Max ( Nm )

Ms Max ( Nm )

Mv Max ( Nm )

Mass at 0 mm stroke (kg)

Additional mass per 100 mm (kg)

52M2P40A - 52M8P40A

650

-

60

4

54

2,41

0,52

52M2C40A - 52M8C40A 650

-

30

4

27

1,65

0,52

52G2P40A - 52G8P40A 1120

1120

60

25

60

3,58

0,52

52G2C40A - 52G8C40A

600

600

25

11

25

2,30

0,52

52R2P40A - 52R8P40A

1200

2000

190

67

118

5,89

0,74

52R2C40A - 52R8C40A 1200

2000

85

67

72

3,84

0,74

52M2P50A - 52M8P50A 800

-

80

17

74

5,30

0,96

52M2C50A - 52M8C50A 800

-

38

17

32

3,50

0,96

52G2P50A - 52G8P50A 1550

1500

200

70

200

7,28

0,96

52G2C50A - 52G8C50A

820

800

60

40

60

4,63

0,96

52M2P63A - 52M8P63A 1400

-

110

17

100

8,10

1,32

52M2C63A - 52M8C63A 1400

-

50

17

48

5,40

1,32

52G2P63A - 52G8P63A 2200

2000

300

102

300

11,02

1,32

52G2C63A - 52G8C63A 1100

1100

105

56

105

7,10

1,32

LOADS AND TORQUE FORCES Ø 40 - 50 - 63