Products designed for industrial applications.

General terms and conditions for sale are available on

www.camozzi.com.Series 5E electromechanical axis

C_Electrics

1

35

>

2017

MOVEMENT >

MOVEMENT

The correct dimensioning of the axis 5E, used individually or

in a cartesian system with several axes, you need to consider

some facts, both static and dynamic. Among these, the most

important are described on the following pages.

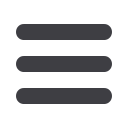

CALCULATION OF LIFE [km]

L

eq

= Life of the axis 5E [km]

C

ma

= Maximum admissible load [N]

C

eq

= Equivalent load [N]

f

w

= safety coefficient according to

the working conditions

CALCULATION OF EQUIVALENT LOAD

When compression/traction and side loads as well as bending

or torque moments act on the system, you need to calculate

the equivalent load acting on the system.

C

eq

= Equivalent load [N]

F

y

= Force acting along the Y-axis [N]

F

z

= Force acting along the Z-axis [N]

C

ma

= Max admissible load [N]

M

x

= Moment along X-axis [Nm]

M

y

= Moment along Y-axis [Nm]

M

z

= Moment along Z-axis [Nm]

M

(x,ma)

= Max admissible moment along X-axis [Nm]

M

(y,ma)

= Max admissible moment along Y-axis [Nm]

M

(z,ma)

= Max admissible moment along Z-axis [Nm]

How to calculate the life of the axis 5E

The electromechanical axis 5E is a self-supporting system and

can also be used between 2 or more supports without the need

of a continuous contact surface.

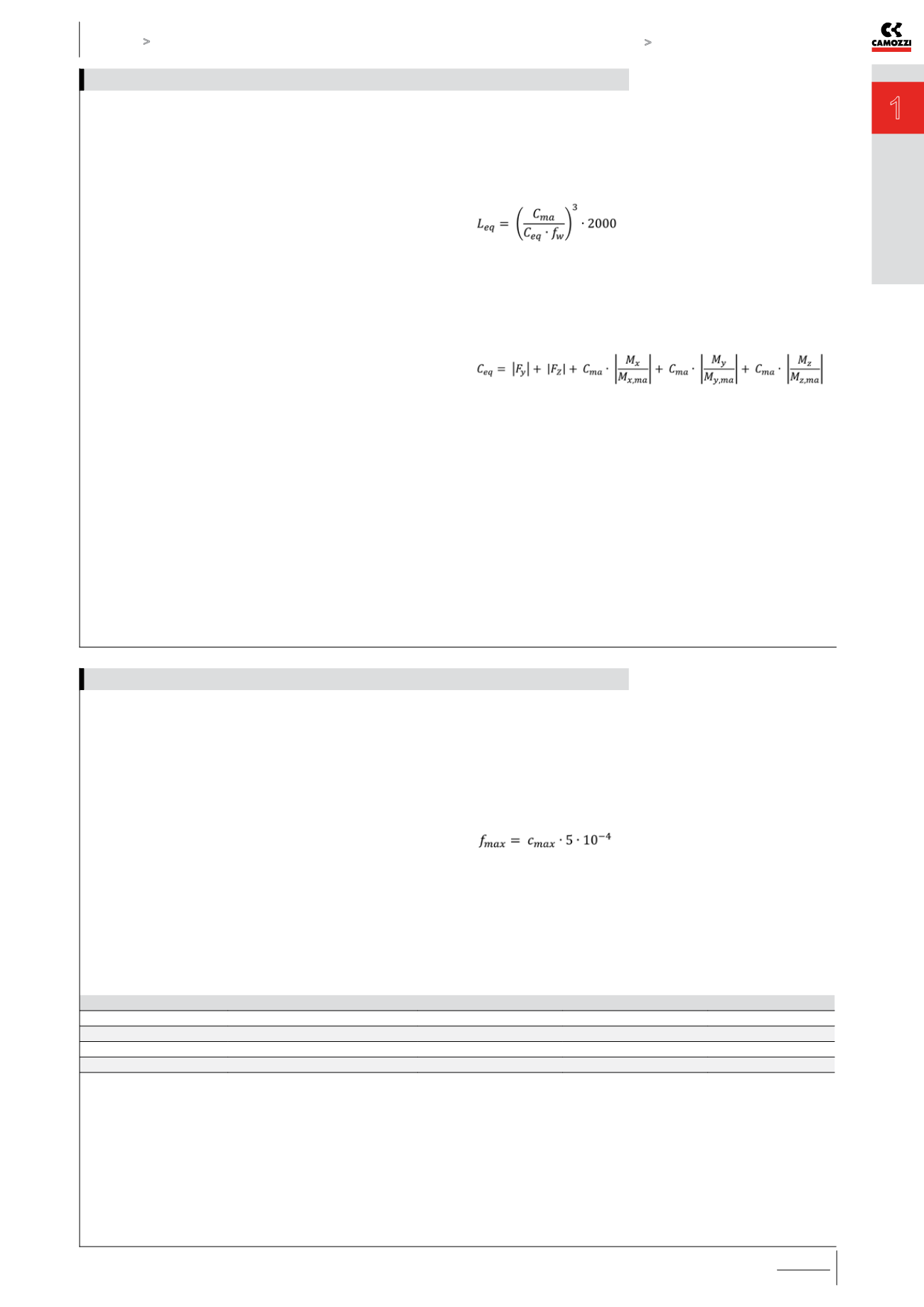

The maximum value of the deflection generated by the

deformation of the system must never exceed the following

calculation:

f

max

= Maximum admissible deflection [mm]

c

max

= Maximum stroke of axis 5E [mm]

NOTE: for a quicker choice, please see the graphs on the

following pages.

APPLICATION

ACCELERATION [ m/s² ]

SPEED [ m/s ]

DUTY CYCLE

fw

light

< 10

< 1.5

< 35%

1 ÷ 1.25

normal

10 ÷ 25

1.5 ÷ 2.5

35% ÷ 65%

1.25 ÷ 1.5

heavy

> 25

> 2.5

> 65%

1.5 ÷ 3

How to calculate the max deflection and verification of distance between supports