119

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

Flow Control Valves NPTF

3

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

FLOW CONTROL VALVES NPTF

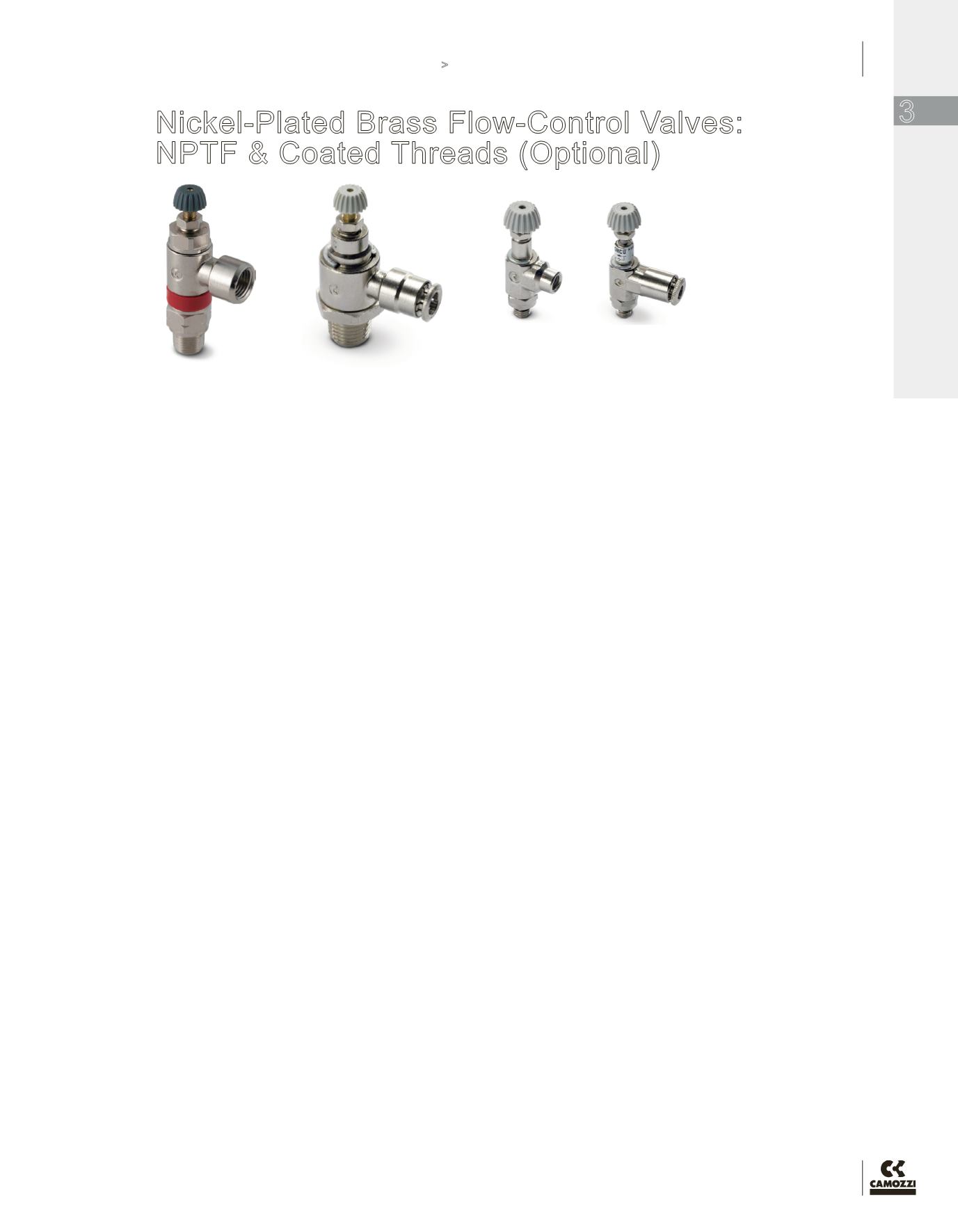

Nickel-Plated Brass Flow-Control Valves:

NPTF & Coated Threads (Optional)

Features

• Nickel-Plated, All-metal Collet and Release

ring

• All-Metal, Nickel-Plated body and Threads,

• Compact Brass bodies from Brass forgings

• Specialized O-ring choices for High-Temp,

Low-Temp, Special Fluids, Food-Grade

compatibility

• Multiple Thread sealant systems: Vibra-Seal

Coated (Optional), Std NPTF & O-Ring Spot

Face seals

• Broad Range of configurations

• Removable Collet and tube o-rings

• Highly accurate Flow-rate repeatability &

Higher Flow

• Manual Adjustment knob w/ internal hex-key

slot or Screw-Driver slot

• Hex Locking-nut

• Precise Manual knob, w/ Internal hex-key

• Full Swivel design, NPTF and Metric/BSP,

with integrated Push-In Fittings or Female

thread ports

• Alternate Non-Swivel design with Banjo Tube

connections and thread adapters

• Meter-IN, Meter-OUT and Needle-Orifice

flow designs for assembly on valves,

cylinders or in-line use

• Alternate sintered bronze banjo for fully

adjustable silencer/muffler with speed control

for exhaust port mounting, ( see Part No.

2905 to add to any banjo flow control body)

Benefits

Collet

• Won’t break like plastic release rings and bodies; More Durable design

• Higher holding force, with easier release

• Won’t scratch tubes like “bite-ring” designs

• Less chance of micro-leakage and bubble-leaks over time due to damaged

tubing

Body

• Resistant to UV exposure

• Better resistance to stress-cracking, abrasion, solvents, detergents,

hydrocarbons and other fluid media

• FDA/NSF approved materials, ( Including customized Nickel-Plating and

o-ring options)

• Simplified manifold circuits with broader variety of fitting combinations and

shapes to select

• Lighter weight for End-of-Arm tooling & Robotic handling,

• Compact design reduces overall dimensions for valve & cylinder

assemblies, packaging applications and control cabinets

• 25 % Reduction in overall Body size, compared to previous Brass-Banjo

line

Design

• Accuracy and Repeatability of Flow-Control valves allows timing circuits

to be design, faster OEM set-up and simplified MRO field installation and

replacements

• Simplified manifold circuits with broader variety of Tube – Thread

combinations to select

• Lighter weight for End-of-Arm tooling & Robotic handling

• Compact design reduces overall dimensions for valve assemblies,

packaging applications and control cabinets

• More compact flow capacity reduces cylinder spacing with improved overall

speed

• Fine tuning of flow with manual knob or screw-driver adjustment

• Convertible into “Tamper-Proof” by removing manual knob or sealing

screw-driver slot

• Interchangeable Inch and Metric Tube O.D. banjo connections and thread

adapters for “hybrid” Fittings and Flow-control valve requirements