General terms and conditions for sale are available on

www.camozzi.com.Series LR digital proportional servo valves

C_FLUID CONTROL CATALOGUE

2

134

>

2018

CONTROL >

CONTROL

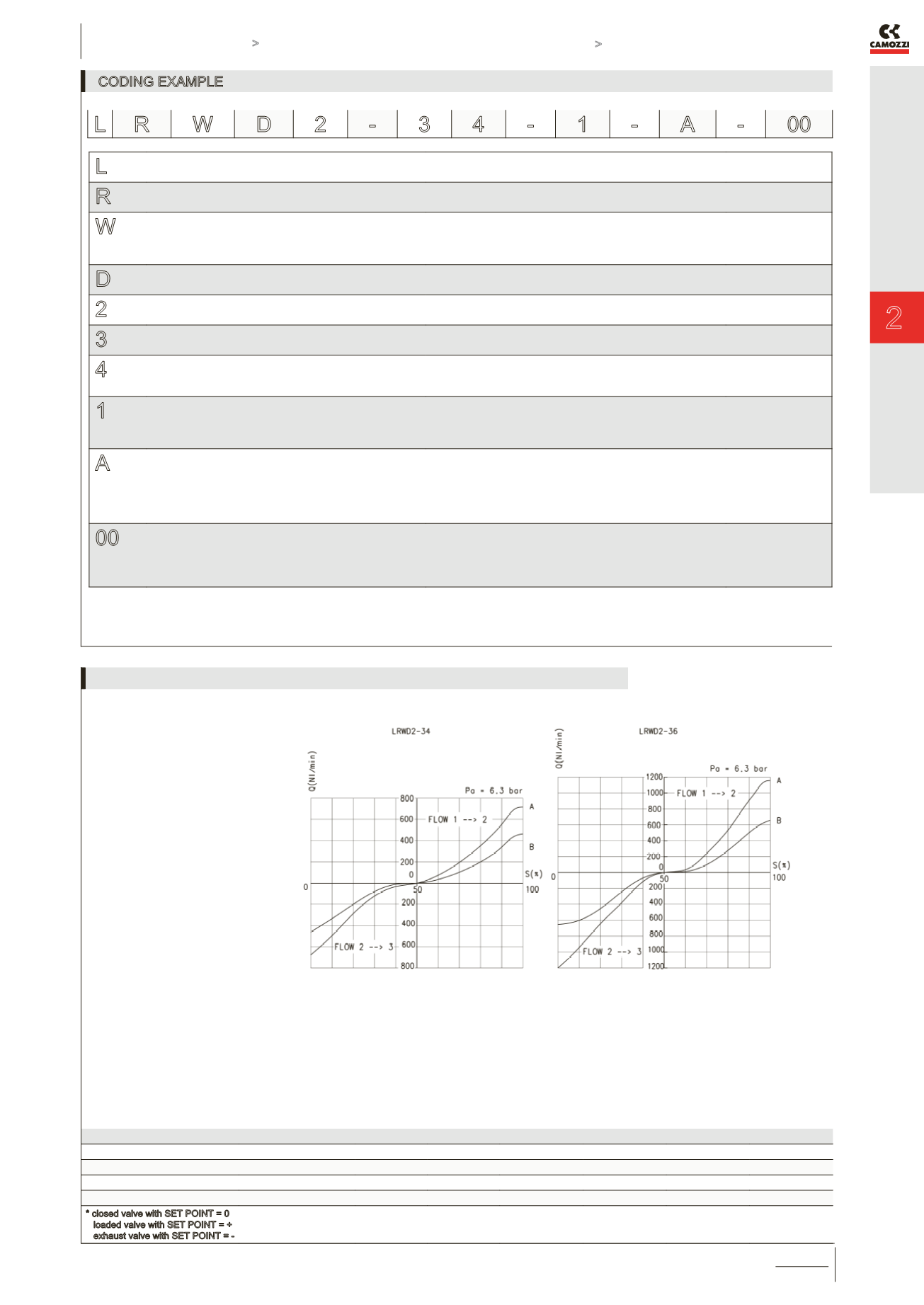

CODING EXAMPLE

L

SERIES:

L = proportional servo valves

R

TECHNOLOGY:

R = rotating spool

W

VERSION:

W = flow control

P = pressure control

X = position control

D

ELECTRONICS:

D = digital

2

MODEL:

2 = compact DIN-RAIL

3

FUNCTION:

3 = 3/3-way

4

NOMINAL DIAMETER:

4 = 4 mm

6 = 6 mm

1

COMMAND SIGNAL (Setpoint):

1 = +/- 10 V

2 = 0 - 10 V

4 = 4 - 20 mA

A

INPUT SIGNAL:

2 = 0 - 10 V (LRPD2 and LRXD2 only)

4 = 0 - 5V (LRPD2 and LRXD2 only)

5 = 4 - 20mA (LRPD2 and LRXD2 only)

A = internal encoder (LRWD2 only)

B = 1 bar (internal sensor - LRPD2 only)

D = 10 bar (internal sensor - LRPD2 only)

E = 250 mbar (internal sensor - LRPD2 only)

F = +1/-1 bar (internal sensor - LRPD2 only)

00

CABLE:

00 = no cable

2F = straight cable of 2 m

2R = 90° cable of 2 m

5F = straight cable of 5 m

5R = 90° cable of 5 m

L R W D 2 -

3 4 -

1 -

A -

00

LEGEND:

A = free flow

B = ∆P1

Q = flow (Nl/min)

S = set point (%)

Pa = inlet pressure (bar)

RESPONSE TIMES ACCORDING TO THE COMMAND SIGNAL IN COMPLIANCE WITH THE ISO 10094-2 STANDARD

COMMAND SIGNAL

-5% ÷ +5% +5% ÷ -5% -25% ÷ +25% +25% ÷ -25% -90% ÷ +90% +90% ÷ -90%

Time [ms] LRWD2-34

4

5

6

9

10

10

Time [ms] LRWD2-36

5

5

6

6

10

10

* closed valve with SET POINT = 0

loaded valve with SET POINT = +

exhaust valve with SET POINT = -

FLOW DIAGRAMS FOR VALVES LRWD2-34 AND LRWD2-36