f l ow con t ro l v a l v e s & a c c e s sor i e s

4

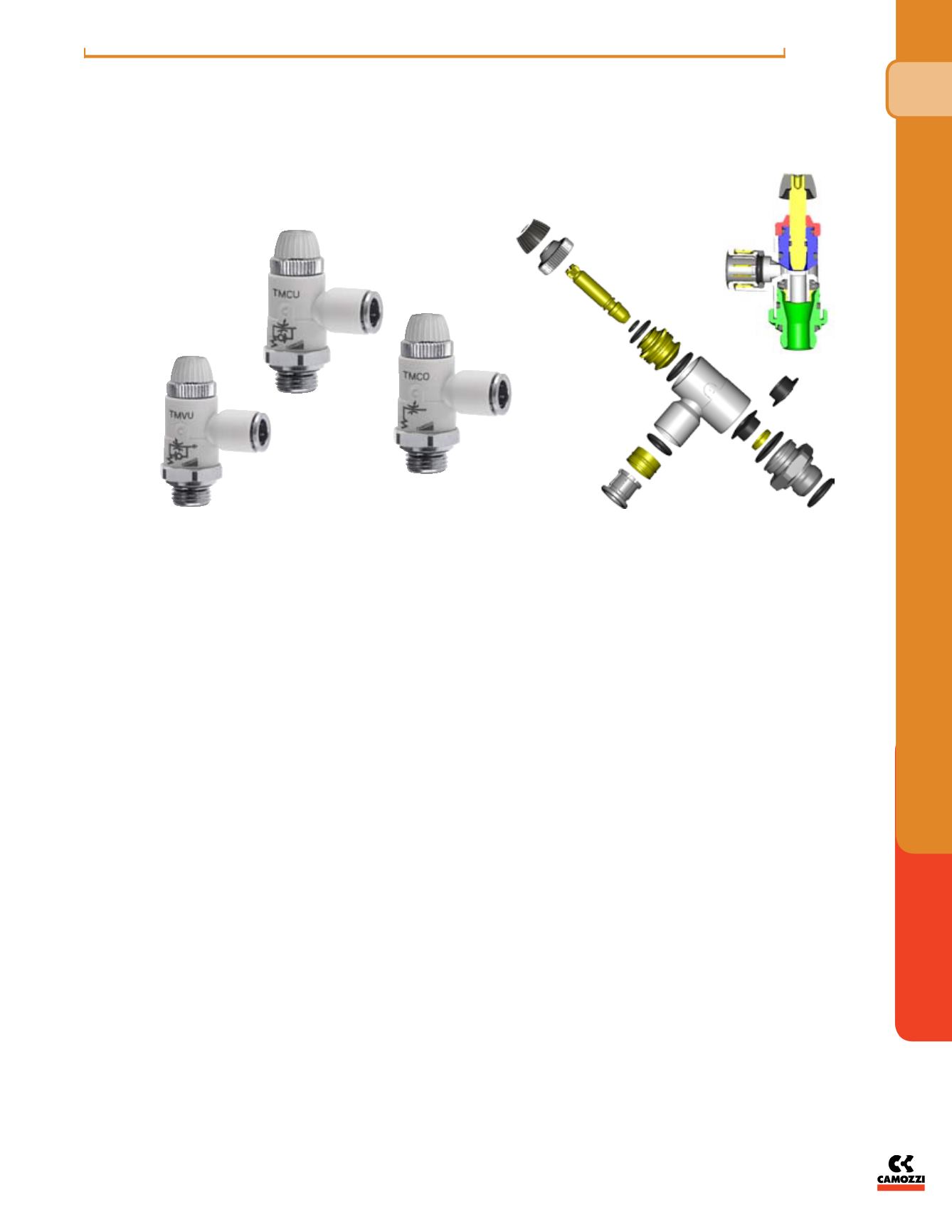

Composite Flow Control Valves:

BSP Threads with Spot-Face O-Ring Seals

Features

• All metal, Nickel-Plated collet and threads

• Strong, specialized Nylon

®

compound body

material

• Specialized O-ring choices for High-Temp,

Low-Temp, Special Fluids, Food-Grade com-

patibility

• Multiple Thread sealant systems: O-Ring

Spot Face seals effectively on BSPP, BSPT or

JIS ( Rpt or Rc , G or Rg) thread ports

• Broad Range of Tube / Thread combinations

• Removable Collet and tube o-rings

• Highly accurate Flow-rate repeatability &

Higher Flow than typical brass bodied flow

control valves

• Large ¼-Turn Locking-nut

• Precise Manual knob, w/ Internal hex-key

• Full Swivel design, NPTF and Metric/BSP,

with integrated Push-In Fittings

• Meter-IN, Meter-OUT and Needle-Orifice flow

designs for assembly on valves, cylinders or

in-line use

• ANSI symbol stamped on all bodies

• Tube O.D. size stamped on all collet faces

• Meter-IN, Meter-OUT and Needle-Orifice flow

designs for assembly on valves, cylinders or

in-line use

Benefits

Collet

• Won’t break like plastic release rings and bodies; More Durable design

• Higher holding force, with easier release

• Won’t scratch tubes like “bite-ring” designs

• Less chance of micro-leakage and bubble-leaks over time due to damaged tubing

Body

• Resistant to UV exposure

• Better resistance to stress-cracking, abrasion, solvents, detergents, hydrocarbons and

other fluid media

• FDA/NSF approved materials, ( Including customized Nickel-Plating and o-ring options)

• Simplified manifold circuits with broader variety of fitting combinations and shapes to

select

• Lighter weight for End-of-Arm tooling & Robotic handling,

• Compact design reduces overall dimensions for valve & cylinder assemblies, packaging

applications and control cabinets

• 10% Reduction in Flow-Control size over previous brass bodies

Design

• Accuracy and Repeatability of Flow-Control valves allows timing circuits to be design,

faster OEM set-up and simplified MRO field installation and replacements

• Simplified manifold circuits with broader variety of Tube – Thread combinations to

select

• Lighter weight for End-of-Arm tooling & Robotic handling

• Compact design reduces overall dimensions for valve assemblies, packaging applica-

tions and control cabinets

• More compact flow capacity reduces cylinder spacing with improved overall speed

• Fine tuning of flow with manual knob or hex-key adjustment

• Convertible into “Tamper-Proof” by removing manual knob and sealing hex-key slot

• Interchangeable Inch and Metric Thread adapters for “hybrid” Fittings and Flow-control

valve requirements. ( Pro-Fit NPTF threads and BSP Spot-Face o-ring seals in opposite

port standards)

compos it e f l ow - con t ro l v a l v e s

b s p/me t r i c

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

149

B S P / M E T R I C

Dimensions in millimeters (mm)