Valve group

3-way/2-position

Construction

Shuttle slide

Mounting

In/line thread ports

Materials

Nickel-Plated brass body, Buna-N seals

Threaded port sizes

M5, 1/8”, 1/4”, 3/8”, 1/2” 3/4" NPTF

Installation

In-line

Operating temperature

32°F - 175°F, (dry air necessary down to 14° F)

Fluid

Filtered air

Lubricant

Not required; otherwise oil compatible with Buna-N, (3°- 10° E) (ISOVG32 grade: 32 centistrokes)

Operating pressure

0 - 10 bar (0 - 145 psi))

Nominal pressure

6 bar (87 psi)

Nominal flow

*Qn Series VMS: P

→

A M5 = 140 NL/min (4.9 SCFM)

1/8” = 600 NL/min (21.2 SCFM)

1/4” = 1200 NL/min (42.4 SCFM)

3/8” = 2100 NL/min (74.1 SCFM)

1/2” = 3350 NL/min (118.5 SCFM

3/4” = 5350 NL/min (189 SCFM

A

→

R M5 = 145 NL/min (5.12 SCFM)

1/8” = 740 NL/min (26.2 SCFM)

1/4” = 1780 NL/min (62.9 SCFM)

3/8” = 1830 NL/min (64.7 SCFM)

1/2” = 4030 NL/min (142.5 SCFM)

3/4” = 5000 NL/min (176.8 SCFM)

Cv Rating (Inlet flow)

Series VMS:

M5 = 0.15

1/8” = 0.63

1/4” = 1.26

3/8” = 2.21

1/2” = 3.53

3/4” = 5.62

*Qn flowrate (SCFM) determined with a supply pressure of 6 bar (87 psi), and with a pressure drop of 1 bar (14.5 psi).

Exhausting flowrate (A

→

R), determined with an inlet pressure of 6 bar (87 psi), while exhausting to atmosphere.

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

24

m a n u a l v a l v e s

1

Dimensions in millimeters (mm)

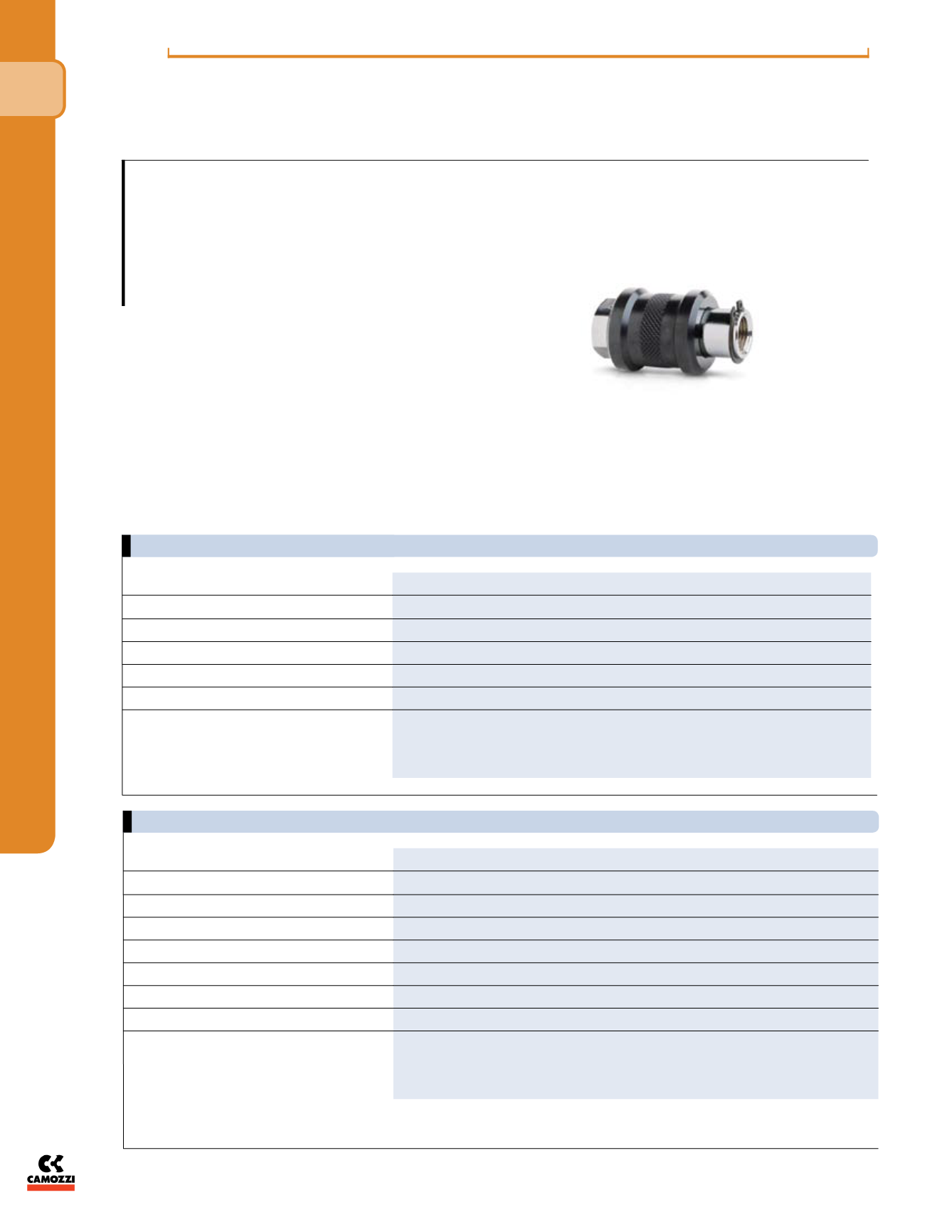

Series VMS

Cv = .73 - 4.10

Slide Valve

Series VMS, 3-way/2-position

Ports M5, 1/8”, 1/4”, 3/8”, 1/2”, 3/4" NPTF

The VMS series slide valves are commonly

used upstream of FRL units to ease repair and

replacement. They can also be used in

situations requiring the exhausting of

all downstream air. This would assist in

maintenance applications where ball valves

may be too large and bulky

to maneuver in tight assembly spaces. The

exhausting of downstream air while

simultaneously blocking inlet flow helps in

building component groups to be tested in

stages, and assembled later onto the main

body of a machine.

TECHNICAL SPECIFICATIONS

PNEUMATIC DATA

Cv = .73 - 4.10