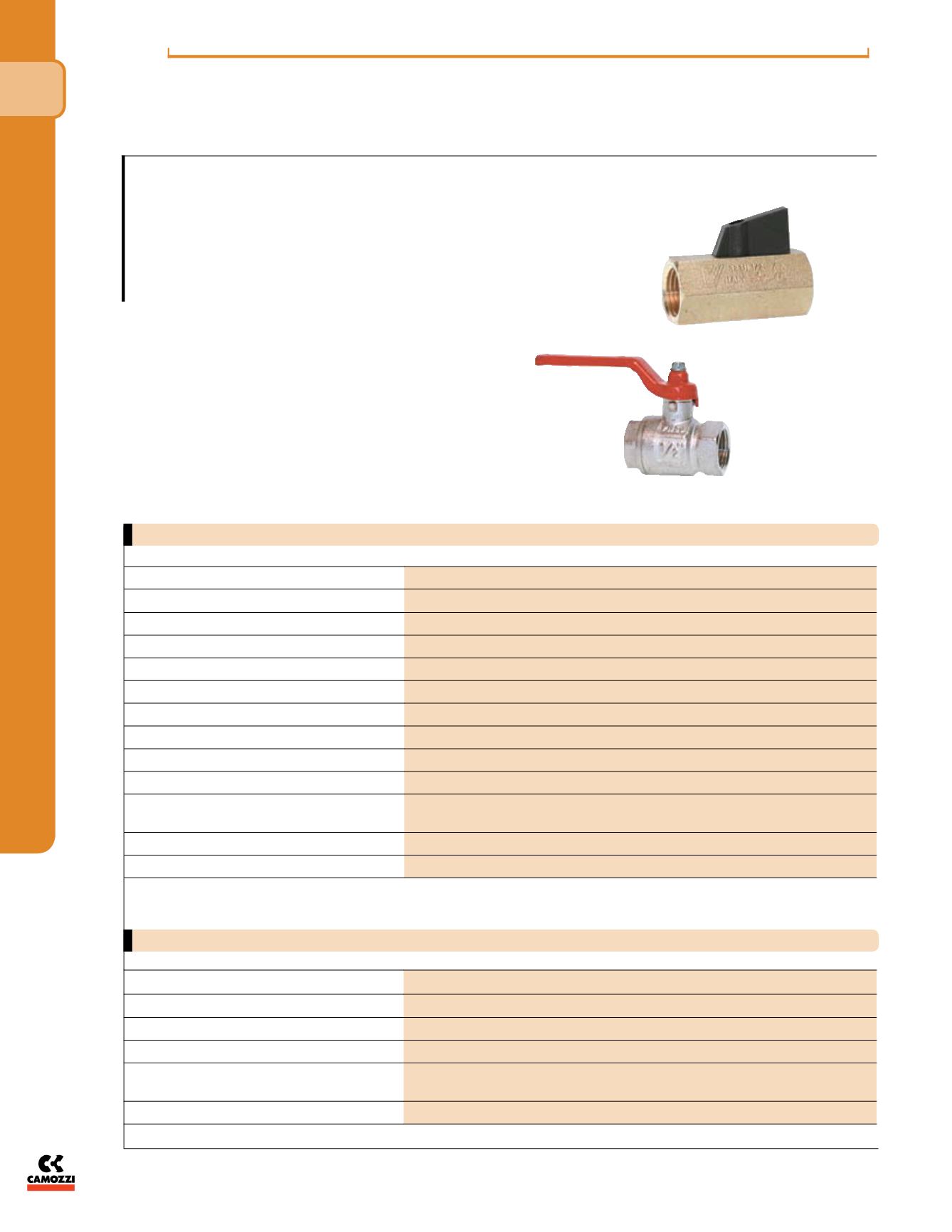

Valve group

2/2, (way/positions)

Construction

Ball valve

Mounting

In-line

Materials

Brass body (2960), Nickel-Plated brass body (2930 and 2940), Chrome-Plated Brass Body (2930N)

Zinc-plated steel handles (2940 and 2960), all others nylon

Plastic handles (2930), Hardened chrome-plated brass ball

Teflon seat (P.T.F.E.), O-rings in Viton

Threaded port sizes

1/8”, 1/4”, 3/8”, 1/2” NPTF (2930)

1/4”, 3/8”, 1/2”, 3/4”, 1”, 1-1/4”, 1-1/2”, 2” NPTF (2940)

Installation

In-line

Operating temperature

Series 2940 - 4°F to 300°F

Series 2960 - 4°F to 340°F

Series 2930 5° to 300°F

Fluid

Filtered air (for others, check with factory)

Working pressure

Series 2940: 1/4”, 3/8”, 1/2”

710 psi

2-1/2” -

260 psi

3/4”, 1”

570 psi

3”

-

230 psi

1-1/4”, 1-1/2”

430 psi

4”

-

200 psi

2” - 360 psi

Series 2930: 1/8”,1/4”, 3/8”, 1/2” 450 psi

Series 2960: All sizes

400 psi

Nominal flow

Full flow design

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

26

m a n u a l v a l v e s

1

Dimensions in millimeters (mm)

TECHNICAL SPECIFICATIONS

PNEUMATIC DATA

Series 2930, 2930N, 2940, 2960

Ball Valves - Full Flow Design - NPTF/INCH

Ports 1/4”, 3/8”, 1/2”, 3/4”, 1”, 1 1/4”,

1 1/2”, 2”, 2 1/2”, 3”, 4”, NPTF

Nickel-Plated (2930 and 2940), Chrome-Plated (2930N) and

Plain Brass (2960)

Electroless nickel-plated: this plating offers

excellent corrosion resistance, and is an FDA-

approved material, making the Camozzi ball

valve suitable for food packaging, chemical

processing, medical, dental, water treatment,

and printing markets, in addition to standard

application.