207

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

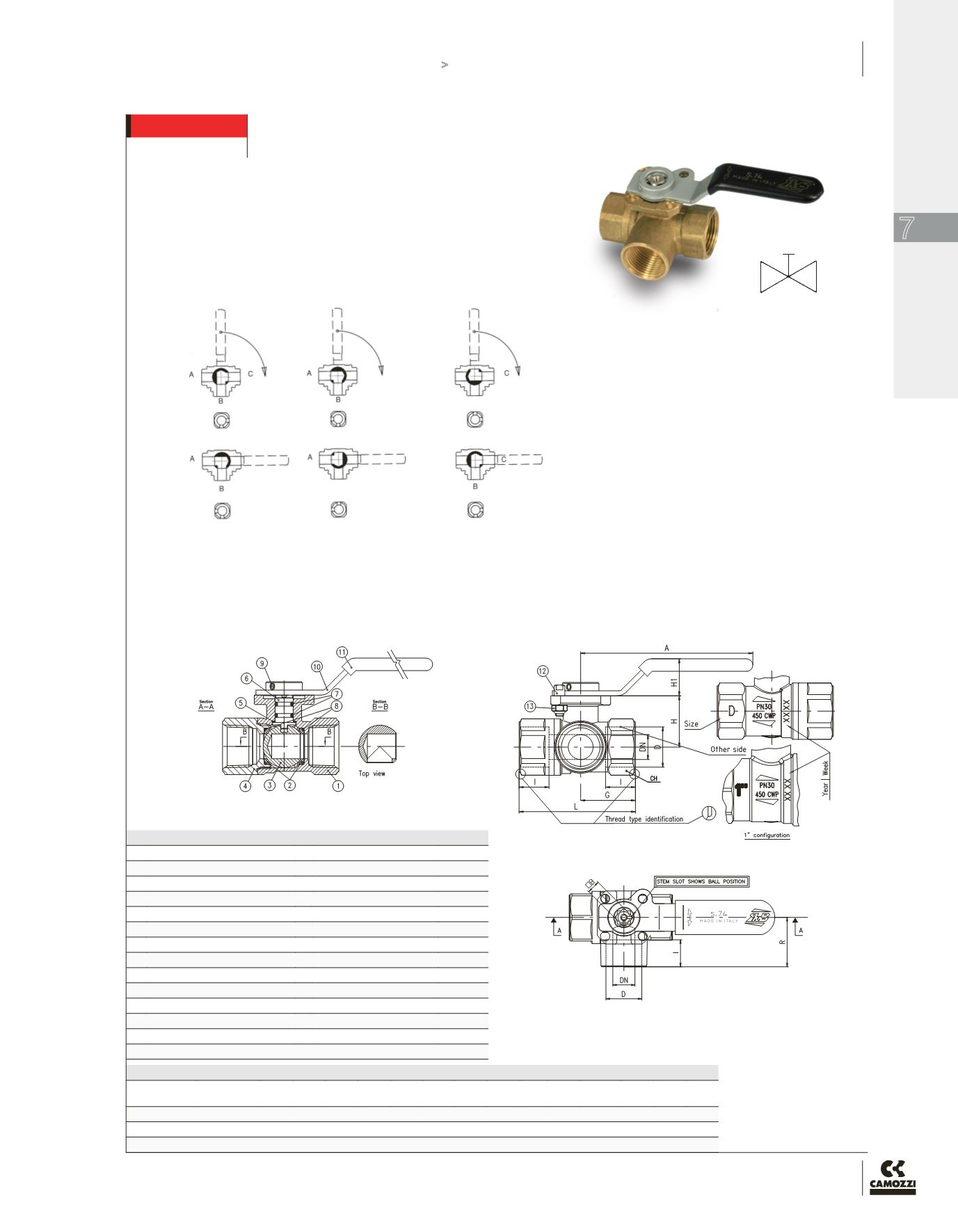

Ball Valves NPTF

7

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

BALL VALVES NPTF

MATERIALS

Part Description

Qty

Material

Standard

1 Sand blasted unplated body

1 CW617N

EN12165

2 Seat

2 PTFE Graphite filled 15%

3 Chrome-plated ball

1 CW617N

EN12164

4 Sand blasted unplated end cap 1 CW617N

EN12165

5 Washer

1 PTFE Carbon filled 25%

6 Nickel-plated stem O-ring design 1 CW617N

EN12164

7 Stem O-ring

2 FPM

8 Seat O-ring

2 FPM

9 Handle screw

1 Steel 4.8

ISO 4026

10 Geomet® steel handle

1 DD11

EN10111

11 Black dipped coating (RAL 9005)

1 PVC

12 Unplated stop

1 CW617N

EN12164

13 Zinc-plated nut

1 Steel 8S

UNI 7474

DIMENSIONS (in inches)

Mod.

D (NPT)

DN I

L

G H H1 CH □ B A R Flow rate

(GPM)

Cv Kg PSI

2960 1/2PT

1/2"

0.591 0.610 2.638 1.299 1.220 0.876 1.220 0.354 4.055 1.220 15

7.0 0.55 450

2960 3/4PT

3/4"

0.591 0.709 2.736 1.299 1.220 0.876 1.220 0.354 4.055 1.319 15

7.0 0.65 450

2960 1PT

1"

0.748 0.827 3.228 1.614 1.516 0.876 1.496 0.354 4.055 1.614 19 12.83 1.20 450

Selector Ball Valve, Series 2960 L-Passage, 3-way/2-position, Lockable

These valves are constructed of a brass body, a

steel handle, a hardened chrome-plated brass

ball, and a teflon seat. These valves are suitable

for industrial, pneumatic, hydraulic, and various

domestic installations. Among the various types of

compounds which can be transported through these

valves are steam, gasoline, fuel, oils, kerosene,

acids, and compressed air.

Ball bores position is by the stem’s milling: A B C = outlets

90û lever rotations

To change outlets combination operation as follow:

Remove the lever; turn the stem into the desired starting position); Reset the lever

Flow Rate in GPM (gallons/

minute H2O) determined with a

pressure drop of 1 psi