From the compressor to the air receiver

The compressed air (C/A) cannot be used immediately, but must be treated to remove impurities such as solids,

water vapour and oil mist. Adequate ventilation, ensuring the air entering the compressor is “clean” and good

maintenance of the compressor, are simplemeasures, which can be taken to limit these impurities.

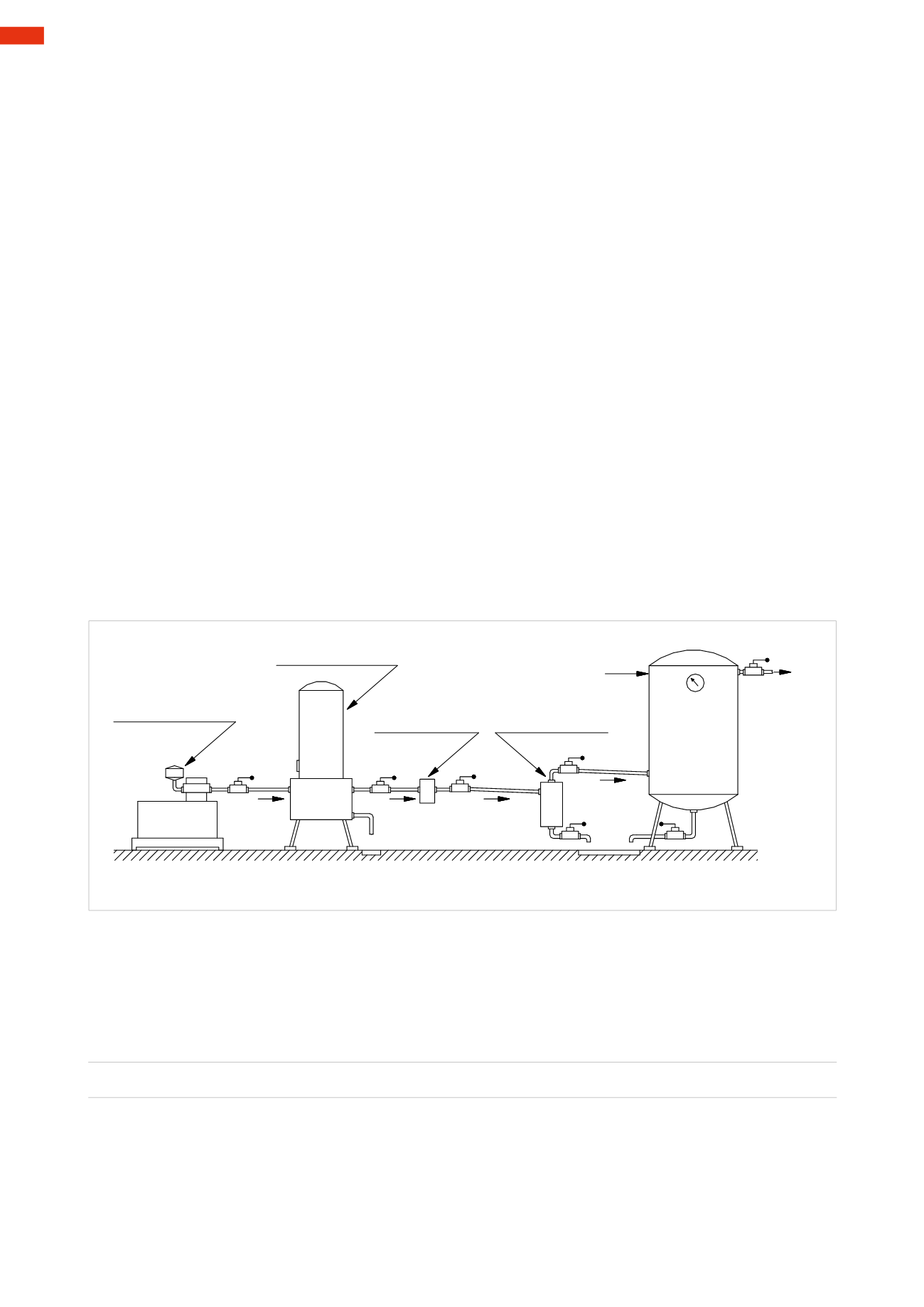

Figure 4

The air drawn into the compressor must pass through intermediate components before reaching the tank:

Suction/Intake filter

: its function is to retain solid particles and themajority of impurities present in the air being

passed into the compressor.

“After-cooler/Refrigerator”

: once the air is compressed, its temperature at the outlet can reach 200

°C

.

The refrigerator cools the air, and as a result converts thewater particles in the air froma gaseous to a liquid state.

Normally, for the operation of cylinders, valves and pneumatic tools the air temperaturemust not exceed 40

°C

.

Tank/Air receiver

: this must be certified, subject to periodic inspection and testing by approved agencies, and

equippedwith a safety valve (which automatically discharges the air if the air pressure exceeds a certain value).

It has several functions:

• dampens the pulsations caused by the reciprocating type air compressors

• allows the temporary use of air at a quantity which exceeds the flow capacity of the compressor

• allows a reserve of compressed air in the event of a power failure

• ensures pressure stability in the network

• favours the storage of condensation

The Tank/air receiver normally has a number of ports or connection points:

• pressure gauge connection in the top cover

• C/A outlet screwed or flanged at the top

• C/A inlet, screwed or flanged at the bottom

• condensate discharge in the lower cover

Along the distribution line of theC/A,

condensation collectors

, are positioned; these are smaller containers, which

collect the condensate, which is formed along the distribution line.

Filter on thecompressor

After-cooler/Refrigerator

Supplementary filter

Condensationcollector

Tank

Fig. 4

Figure 5

Pos. 1

: the air we breathe contains humidity from the evaporation of theworld’s surfacewater. This is particularly

evident during the summer months when high humidity canmake it difficult to breathe.

1

m

3

of free air at 25°

C

contains 23 g of water in the form of steam.

To obtain 1

m

3

of air at 6 bars pressure, 7

m

3

of free air must be compressed.

23 * 7=161grams of water for every

m

3

of compressed air

This water vapour, if not eliminated, will enter the distribution system, condense and then contaminate the

equipment resulting in reduced working life and component failure. In the after-cooler, cooling the C/A can be

done in twoways: by air or water.

The principle of operation of the refrigerator is based on the exchange of heat by conduction. The hot C/A passes

through a cylinder in which there is a network of tubes in which water circulates. The air, when in contact with

these pipes, decreases in temperature and this reduction in temperature reduces the ability of the air to hold

water in its vapour form and a large proportion of the vapour condenses into the liquid. The accumulatedwater is

channeled to the outlet.

2

40

CAMOZZI

>

AIRPRODUCTIONANDPREPARATION