AIR PRODUCTION AND PREPARATION

Fig. 3

Fig. 2

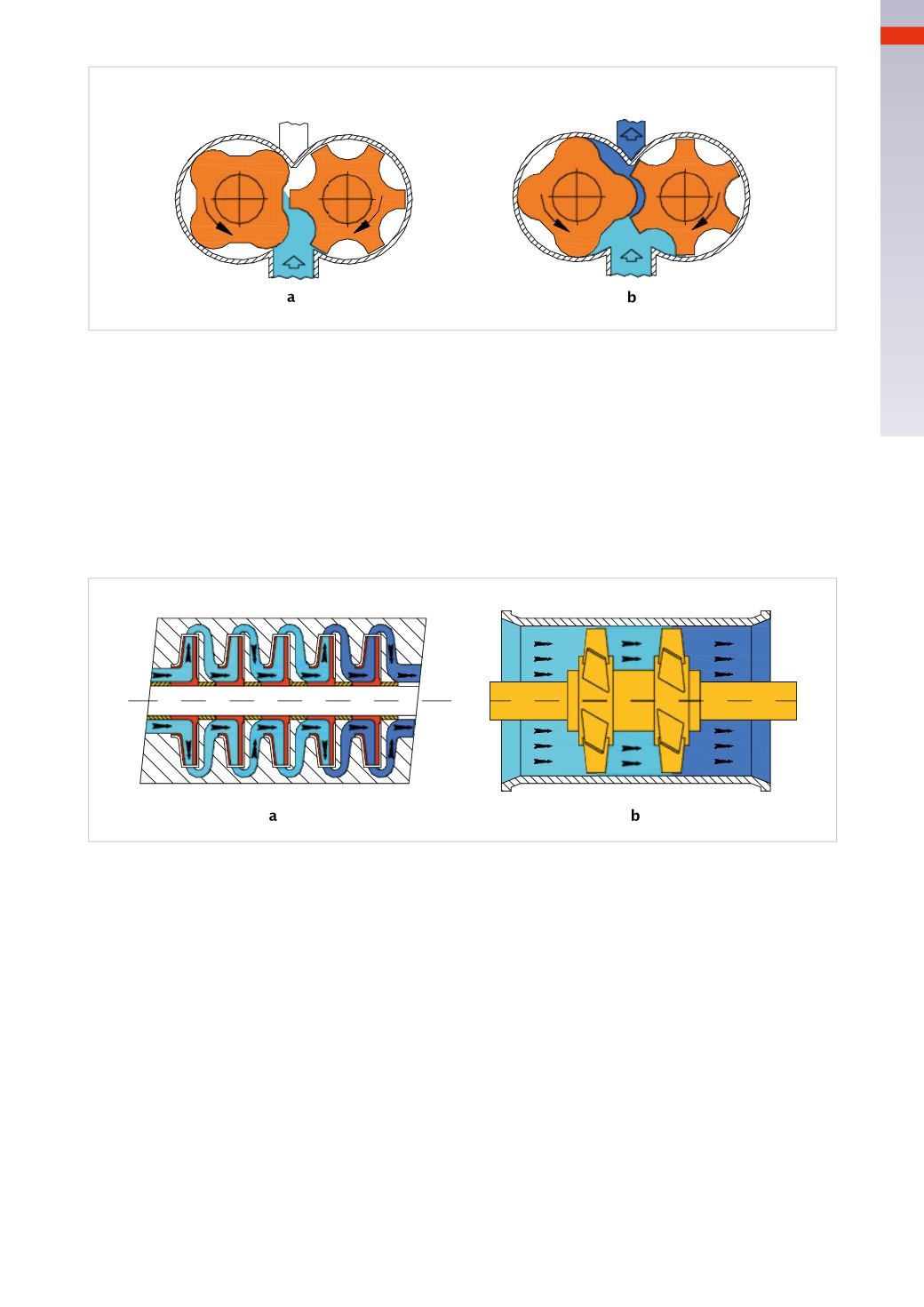

Figure 3

Operation of the dynamic compressors

.

These compressors areused to compress large quantities of air; theywork on the principle based on themovement

of air using impellerswith blades. The kinetic energy that the air acquires is converted into pressure energy before

it exits from the compressor.

Depending on the shape of the impeller the compressor is classified as

radial

or

axial

.

a)

Radial

The first impeller receives free air and projects it radially towards a pipe connected to the inlet of the second

impeller, and so forth. In each step there is an increase of pressure.

b)

Axial

Themovement of air maintains a directionwhich is parallel to the axis of the impeller.

Selecting your compressor

.

Themost important factor to define is the amount of air required (output capacity) which is calculated in

Nm³

/

h

.

Thismust correspond to the demands of the equipment to be operated.

The air consumption can be continuous or intermittent:

Continuous

: machinery, equipment, utilities that are kept in continuous operation throughout the day. To this

value, the sum of all leakage points from equipment as well as the air distribution system itself must be added.

Intermittent consumption

: includes drills, grinders, screwdrivers etc.

Themanufacturer of the latter type of equipment provides the air consumption as a function of pressure and time.

Knowing theperiod inwhich they areused, it is possible toquantify theamount of air consumed in this unit of time.

Regarding the cylinders and the respective connecting tubes, the calculation of the consumptionwill be discussed

later. In general it is advisable to choose a compressor capable of providing a quantity of air, which is 50% greater

than required, and to connect a tank downstream of the compressor itself.

2

39

CAMOZZI

>

AIRPRODUCTIONANDPREPARATION