Treatment of compressed air

Characteristics of air

The presence of dust, moisture and oil vapours in the air contribute to the deposition of scale, which can create

problems for the components as well as deterioration of the distribution network.

Themost frequent problems are:

•Deterioration of the sealing elements in the pneumatic components and the consequent increase in friction.

• Increasedmaintenance costs of components and equipment.

• Increase in cycle time.

• Increased pressure drop and decrease in the final yield.

These impurities must be removed from the compressed air network, as the barriers installed at the compressor

outlet are insufficient, therefore it is essential to fit a

filtering device

at the inlet points.

The filtering devicesmust ensure an optimal air purificationminimizing the drop in pressure.

Characteristics of the fluid

The impurities in the air can be of different types, and depending on the application sector, different purification

needs are required.

In our case, we consider only the elements indicated above, we don’t take bacteriological contaminations into

consideration as we are referring to components and filtration systems used in traditional industries.

The

International Standard ISO-DIN8573-1

defines the characteristics of the fluid on the basis of the classes and

the traditional impurities. The classification ismade according to:

•Number of

solid particles

present in a

m

3

of air relative to their diameter.

• Temperature at which, at constant pressure, the compressed air starts to condense thewater vapour.

Moisture is always present in the air in the form of

water vapour

, to be able to remove it, it is necessary to lower

the temperature by using coolers or dryers.

•Maximum concentration of

oil

.

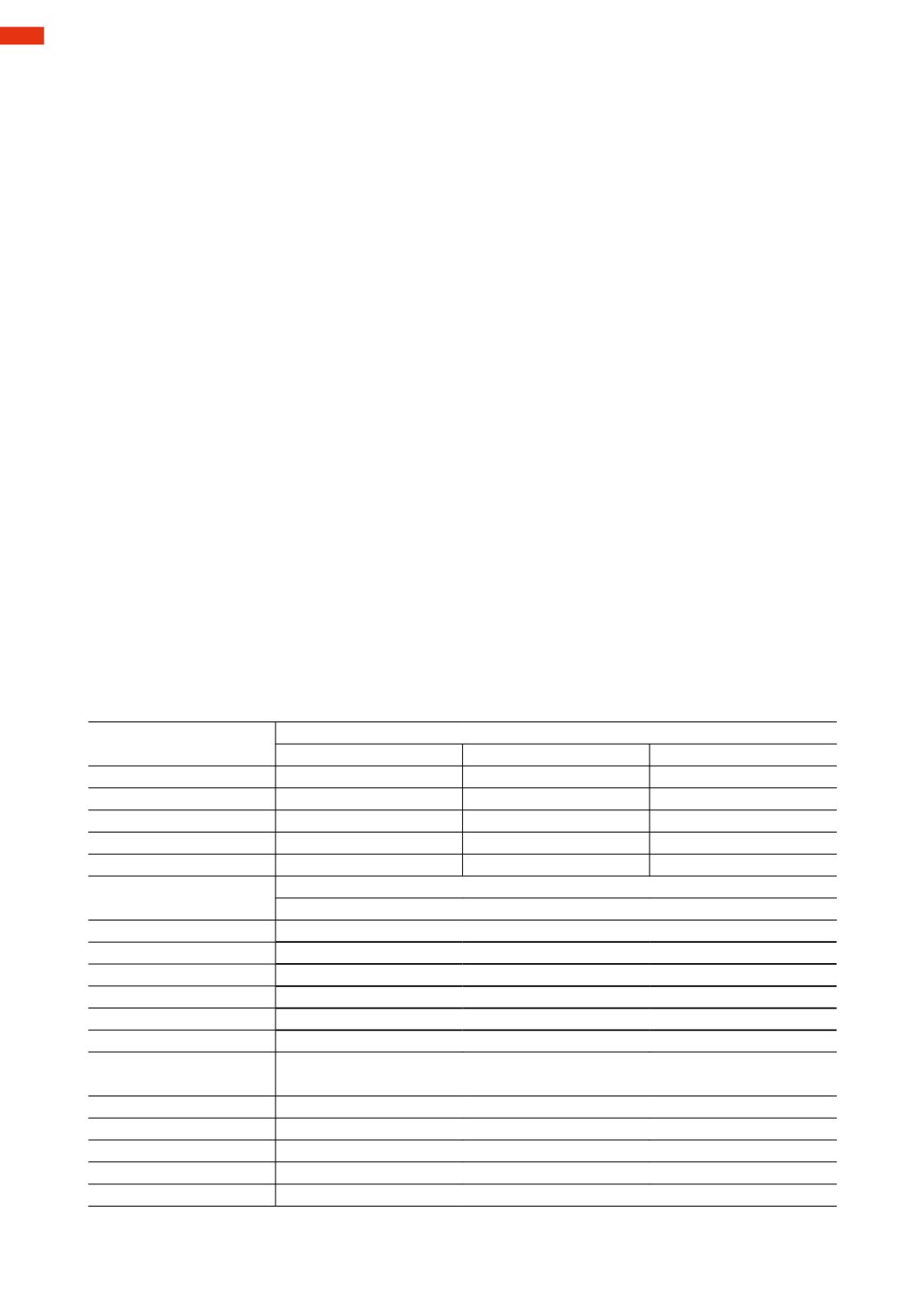

The table shows themaximum allowable values for all elements according to the defined class.

The quality of air required by components suited for amining environment is not the same as the quality request

from components designed for applications in the food or pharmaceutical sectors.

There are specific filtration systems for the different contaminants, and groups comprised of varying filtration

elements with different characteristics can bemade.

Class

Maximum number of particles present in a

m

3

according to their diameter

0,1 µ

m< d

≤

0,5 µ

m

0,5 µ

m

< d

≤

1 µ

m 1 µm< d

≤

5 µm

1

≤

20.000

≤

400

≤

10

2

≤

400.000

≤

6000

≤

100

3

≤

90.000

≤

1000

4

≤

10.000

5

≤

100.000

Class

Content of water

Temperature of water condensation

1

≤

-70°

2

≤

-40°

3

≤

-20°

4

≤

+3°

5

≤

+7°

6

≤

+10°

Class

Concentration of oil mg/m

3

1

≤

0,01

2

≤

0,1

3

≤

1

4

≤

5

5

≤

5

2

44

CAMOZZI

>

AIRPRODUCTIONANDPREPARATION