CYLINDERS

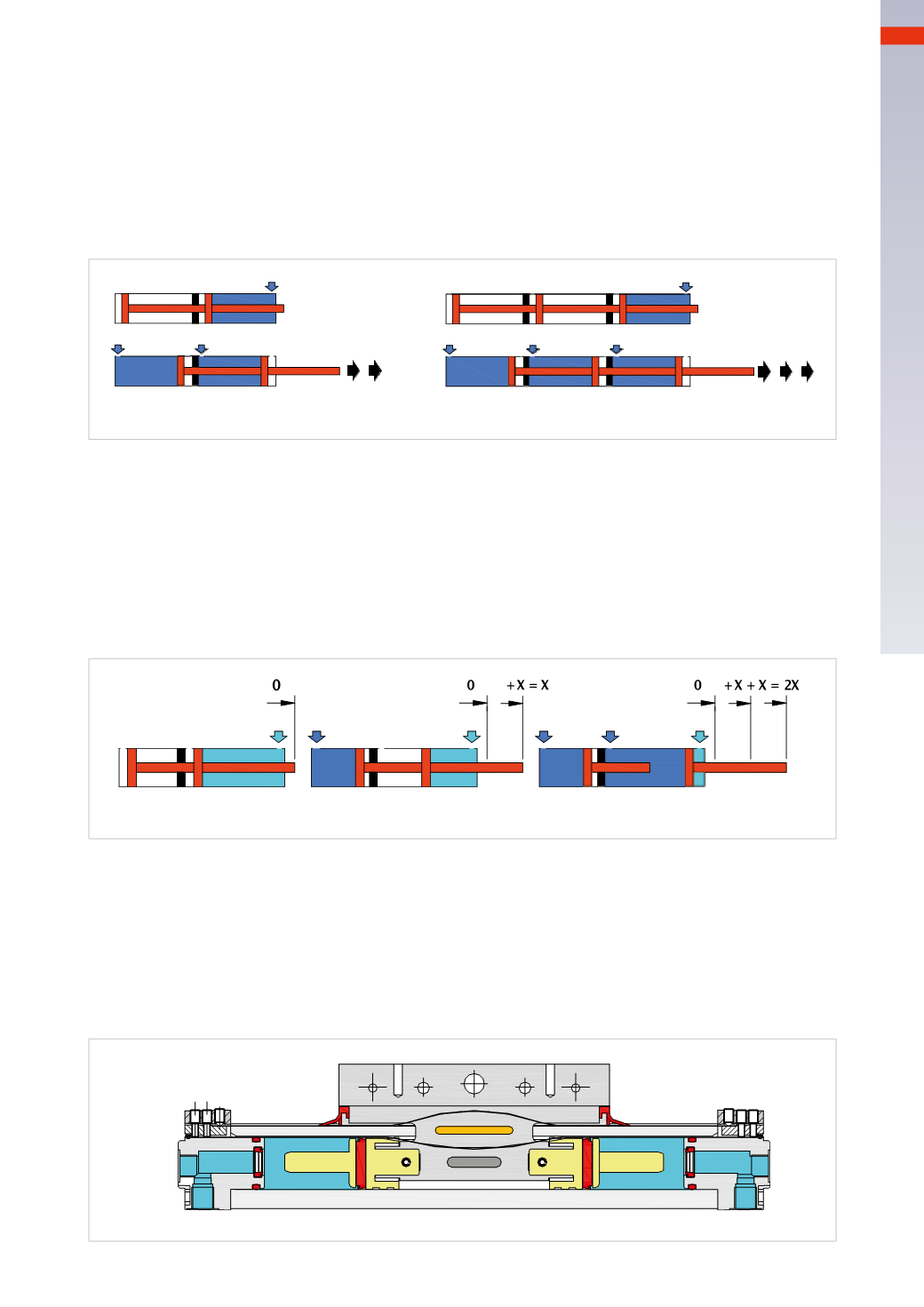

Figure 35

Tandem cylinders

We have already verified that the Force generated by a cylinder depends on the pressure and the (surface area)

diameter of the piston.When a large Force is required but the space available for a cylinder with a large piston is

limited, an alternative solution can be cylinders in tandem (tandem cylinders).

The tandem cylinder consists of a single cylinder with two positive and negative chambers and two pistons where

the piston rod of the first piston ismechanically connected to the second one. The resulting thrust Force is given,

(slightly reduced by the friction), by the sum of the surface areas of the two pistons and the pressure acting on

them. Tandem cylinders can have many consecutive pistons and are defined as with 2, 3 or 4 phases based on

their number of pistons.

Fig. 35

Figure 36

Multi-position cylinders

When different positions are required at the piston rod piston, the cylinder used is amultiple-position cylinder.

It is comparable to the solution where the first piston pushes the adjacent one, which pushes the one

adjacent to it and so on. The cylinder strokes can be all the same, or different. Pneumatically feeding the

front chamber of the piston an effect of air spring is created, which repositions all the pistons at the rear end.

Maintaining limited pressure on the front chamber and subsequently feeding the rear chambers you can attain

various stroke lengths. The same situation occurs in the reverse direction, after exhausting the rear chambers.

It is important tomaintain constant pressure (of a relatively low value) in the front chamber of the cylinder to avoid

unwanted positions.

Fig. 36

Figure 37

Rod-less cylinders

In this type of cylinder, there is no rod, but there is an external carriagemechanically connected to the piston inside

the cylinder is end block. The end block is cut longitudinally and the seals aremade of steel plates, or soft seals

with a specific profile. Since there is no rod, the thrust and traction surfaces are perfectly equal and therefore,

with the same pressure, the cylinder Force is exactly the same. The benefit of this type of construction is the

reduced dimension, compared to that required of a normal cylinder, which doubles its length when the piston

rod is extended. These cylinders are mainly used in long stroke applications and where there is a limited space.

When the stroke length is short however, this characteristic is not valid.

Fig. 37

3

81

CAMOZZI

>

CYLINDERS