CYLINDERS

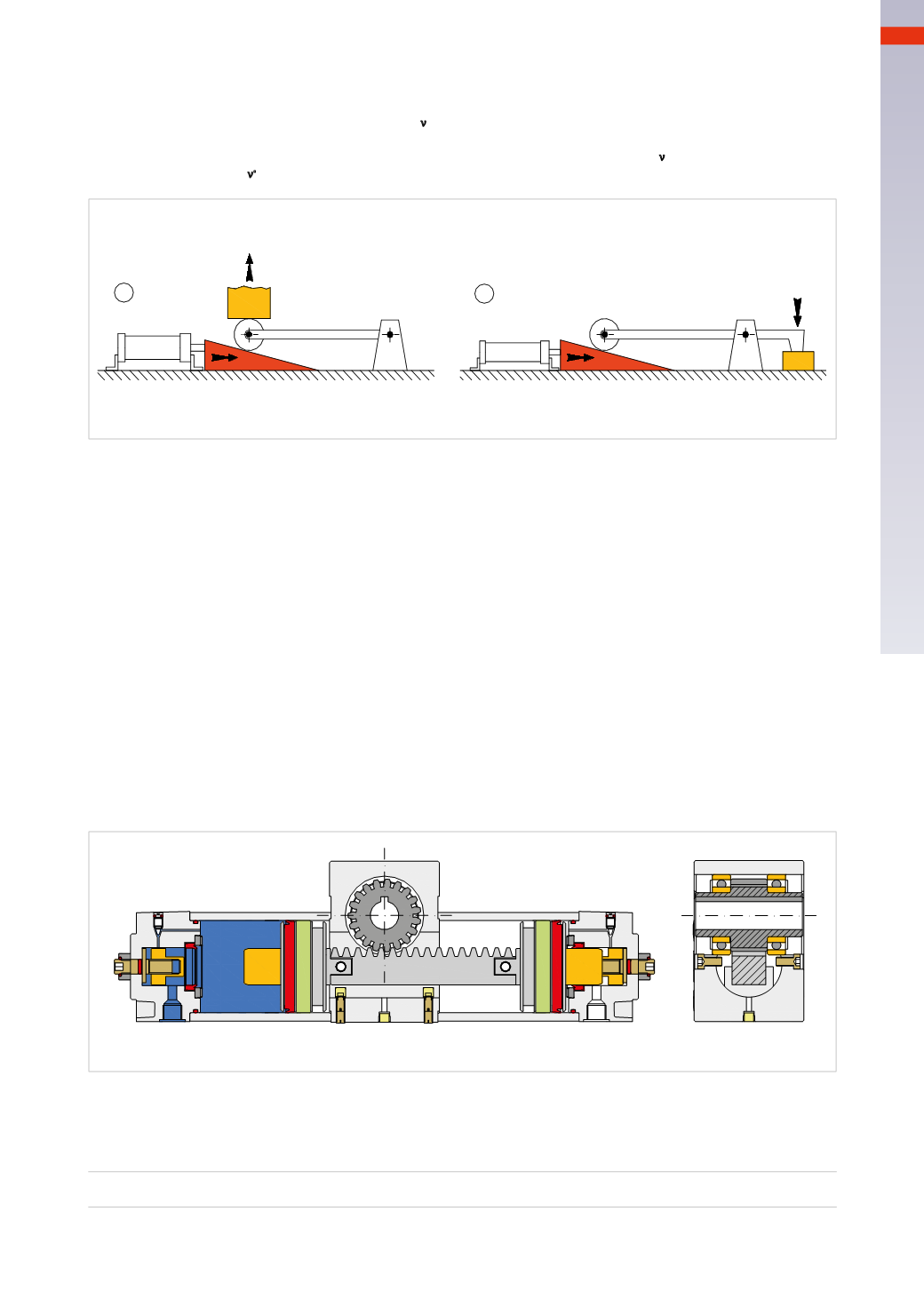

The figures below show how the wedge can be used.

Figure 27

Pos. A

: the sliding friction between load surface

F

ν

and the inclined plane during the lifting phase is transformed

into rolling friction by means of a round body supported by an arm, in this way improving the working conditions.

Pos. B

: this wedge/lever combination improves the ratio between Force

F

s

and Force

F

ν

. It also changes the point

of application of Force

F

ν

.

B

A

Fs

Fv

Fs

Examples of wedge application in equipment

Fv

Fig. 27

Rotary cylinders

Figure 28

The rotating cylinder possesses a number of the features discussed in previous chapters where we illustrated how

to connect a traditional cylinder to a crank or a gear. The pinion/rack group is an integral part of the rotary cylinder

and is connected to the two pistons which each have a magnetic ring in their respective chambers.

The movement of the pistons carries the movement of the rack. The heads are equipped with adjustable end

cushioning and angular adjustment screws; there are also set screws on the central body to offset the slack between

the rack and pinion. The angles of rotation on these cylinders are normally 90° and 180°.

The rotation angle depends on the length of the rack and the number of teeth of the pinion.

The

torque force

M

t

; of the rotary actuator is defined by the distance (in meters) between the axis of the pinion

and the rack, in combination with the thrust Force acting on the rack, this value is decisive in the choice of the

cylinder. This torque Force expressed

Kgm

or

Nm

is obtained by multiplying the thrust Force of the piston acting

on the rack, by the rolling pitch diameter.

Fig. 28

Figure 29

Pos. 1

:

a

indicates the distance between the axis of the pinion and the axis of the rack, and

F

1

indicates the Force

developed by the piston, the torque Force of the cylinder is equal to the product of the two values, namely:

M

t

=

F

1

* a

The Force is expressed as a derivative of the pressure, as is the torque.

3

77

CAMOZZI

>

CYLINDERS