228

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

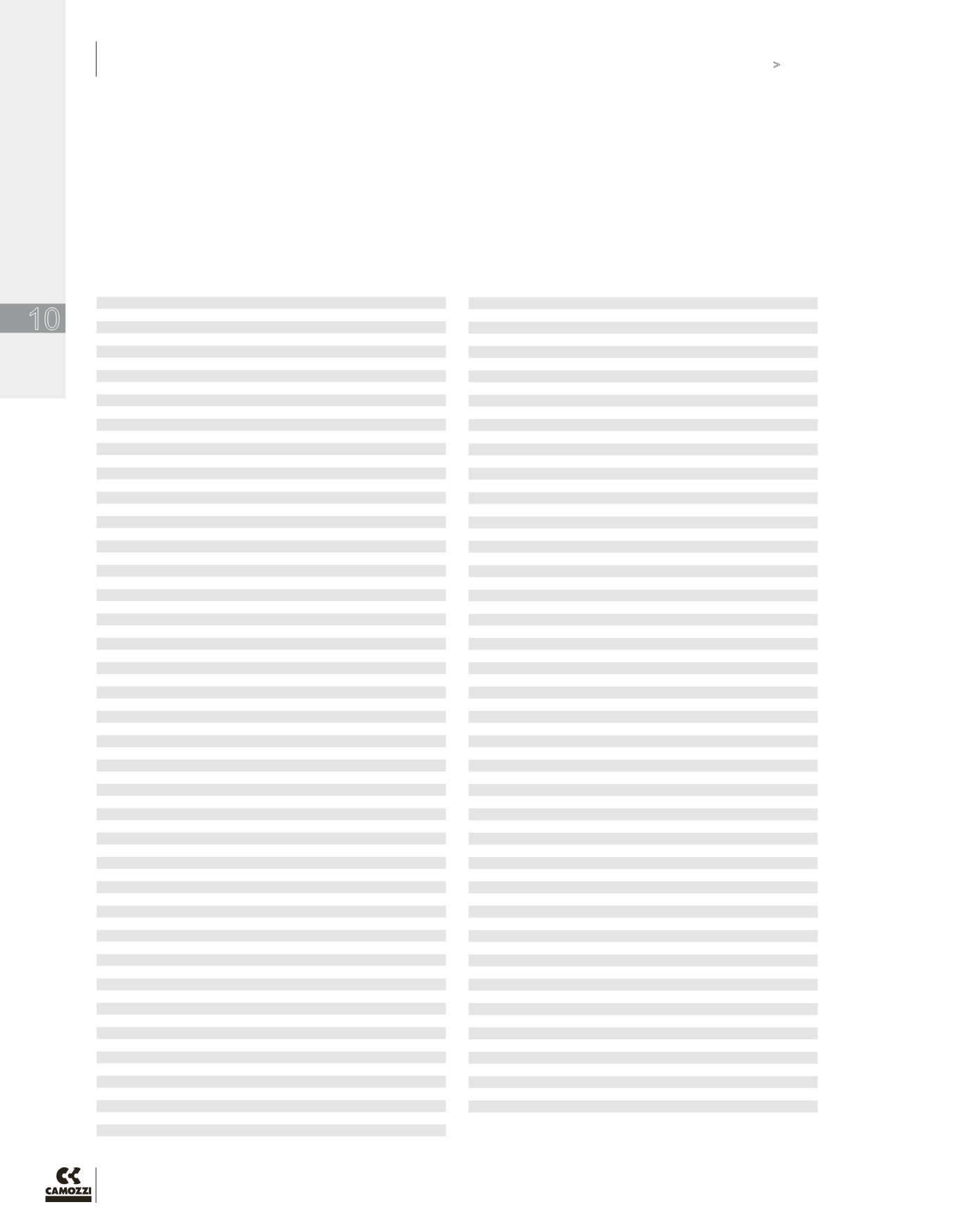

TECHNICAL DATA

Technical Data

10

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

Substance

%

Concentration

Temp.

Deg.C Resistance

Acetic Acid

0-70

Ambient

B-C

Acetone

100

54

A-B

Acidic Well-Water

-

20-4

B

Aliphatic Acid

100

Ambient

B

Aluminum Chloride

saturated

Ambient

D

Aluminum Sulphate

saturated

Ambient

B

Ammonium Chloride

saturated

Ambient

B

Ammonium Hydroxide

5-28

Ambient

C

Ammonium Nitrate

saturated

Ambient

B

Amyl Alcohol

100

Ambient

A

Amyl Chloride

100

Ambient

A

Aviation Gasoline

100

Ambient

A

Barium Chloride

2-40

Ambient

A

Barium Hyroxide

2-50

60

A

Beer

-

10

A

Benzil Acid

saturated

Ambient

D

Benzyl

100

Ambient

A

Boiling Oil

100

Ambient

A

Borax

saturated

Ambient

B

Boric Acid

saturated

Ambient

C

Bromine

100

Ambient

B

Butane

100

25

A

Butyl Alcohol

100

Ambient

A

Calcium Chloride

saturated

Ambient

A

Calcium Hydroxide

saturated

60

A

Calcium Nitrate

saturated

Ambient

A

Carbon Dioxide

100

Ambient

B

Carbon Tetrachloride

100

@ boiling point

A

Chlorine

100

Ambient

B

Chloroform

100

@ boiling point

B

Chloroform

100

Ambient

A

Chromic Acid

2-100

Ambient

D

Citric Acid

5

Ambient

A

Coal Oil

100

Ambient

A

Coffee

@ boiling point

A

Copper Chloride

saturated

Ambient

D

Copper Nitrate

saturated

Ambient

D

Copper Sulphate

2-30

Ambient

C

Crude Oil

100

Ambient

A

Dichloro Ethylene

100

@ boiling point

A

Dichloro Ethynol

100

Ambient

A

Dimethyl Benzol

100

Ambient

A

Distilled Water

Ambient

A

Drinkable Water

80

A

Dry Chlorine

100

Ambient

A

Ethyl Acid

100

Ambient

A

Ethylene

100

Ambient

A

Ethylic Glycol

100

Ambient

A

“Exhaust Gas, Basic”

260

D

“Exhaust Gas, Oxidative”

540

A

Ferrous Chloride

saturated

Ambient

D

Ferrous Nitrate

saturated

Ambient

D

Ferrous Sulphate

saturated

Ambient

D

Formaldehyde

37

Ambient

B

Formic Acid

88

Ambient

B

Fruit Juice

Ambient

A

Gas

100

Ambient

A

Glucose

saturated

Ambient

A

Glycerine

100

Ambient

A

Hydrochloric Acid

30

Ambient

D

Hydrochloric Acid

conc.

Ambient

D

Hydrochloric Acid

10

Ambient

D

Hydrochloric Acid

20

Ambient

D

Hydrofluoric Acid

2-100

Ambient

D

Hydrogen Sulphide

100

Ambient

A

Iron Chloride

saturated

Ambient

D

Kerosene

100

Ambient

A

Lactic Acid

85

Ambient

A

Lactic Acid

10-50

Ambient

C

Lead Acetate

saturated

Ambient

B

Substance

%

Concentration

Temp.

Deg.C Resistance

Lead Nitrate

saturated

Ambient

A

Linseed Oil

100

Ambient

A

Lithium Chloride

saturated

Ambient

A

Magnesium Chloride

2-50

Ambient

A

Magnesium Hyroxide

2-50

Ambient

A

Molasses

100

B

Molasses

Ambient

A

Methyl Alcohol

100

Ambient

A

Methyl Chloride

100

Ambient

C

Milk

Ambient

A

Mineral Oil

100

Ambient

A

Natural Resin

100

50

A

Nickel Chlorine

saturated

Ambient

C

Nickel Sulphate

saturated

Ambient

C

Nitric Acid

2-100

Ambient

D

Oleic Acid

100

Ambient

A

Oleum

20

Ambient

D

Orange Juice

Ambient

A

Oxalic Acid

saturated

Ambient

A

Palm Oil

100

Ambient

A

Paraffin

100

Ambient

A

Peanut Oil

100

Ambient

A

Phenol

100

90

A

Phosphoric Acid

0-100

Ambient

0-10% C

Ambient

10-80 % B

Picric Acid

100

Ambient

D

Polymers

100

20...200

A

Potassium Carbonate

saturated

Ambient

A

Potassium Chloride

saturated

Ambient

A

Potassium Hydrate

2-50

Ambient

A

Potassium Ironcyanide

saturated

Ambient

B

Propane

100

Ambient

A

Rosin

100

@ boiling point

A

Sea Water

Ambient

A

Silver Chloride

saturated

Ambient

D

Soap

95

A

Sodium Bicarbonate

saturated

Ambient

B

Sodium Carbonate

saturated

Ambient

A

Sodium Chloride

saturated

Ambient

A

Sodium Cyanide

5

Ambient

B

Sodium Hydrate

2-73

>=60

A

Sodium Nitrate

10

Ambient

A

Sodium Phosphate

saturated

Ambient

A

Sodium Sulphate

saturated

Ambient

A

Sodium Sulphide

saturated

Ambient

A

Steam

425

A

Steam Condensate

80

A

Stearic Acid

saturated

Ambient

A

Sulphuric Acid

20

Ambient

C

Sulphuric Acid

50-70

Ambient

C

Sulphuric Acid

30-40

Ambient

C

Sulphuric Acid

90

Ambient

C

Sulphuric Acid

10

Ambient

D

Sulphuric Acid

80

Ambient

D

Sulphuric Acid

100

Ambient

D

Sulphurous Acid

2-60

Ambient

D

Tanning Solution

100

Ambient

A

Toluol

100

95

A

Trichlorethylene

100

95

A

Turpentine

100

Ambient

A

Urine

saturated

Ambient

A

Vinegar

100

Ambient

B

Vinyl Chloride

100

35

A

Whiskey

Ambient

A

Wine

100

Ambient

A

Zinc Chloride

saturated

Ambient

B

Zinc Nitrate

saturated

Ambient

B

LEGEND:

A: Very satisfactory result, rate of removal from corrosion less than 2.5 microns per year.

B: Useful result, rate of removal from corrosion less than 12.5 microns per year.

C: To be decided in each case individually, rate of removal from corrosion less than 25 microns per year.

D: Application not recommended for long periods, rate of removal from corrosion more than 25 microns per year.

Corrosion Resistance of Electrolytic Nickel Plating

for Chemicals

Camozzi fittings

are plated at a

thickness of 5-8

µm (microns).