229

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

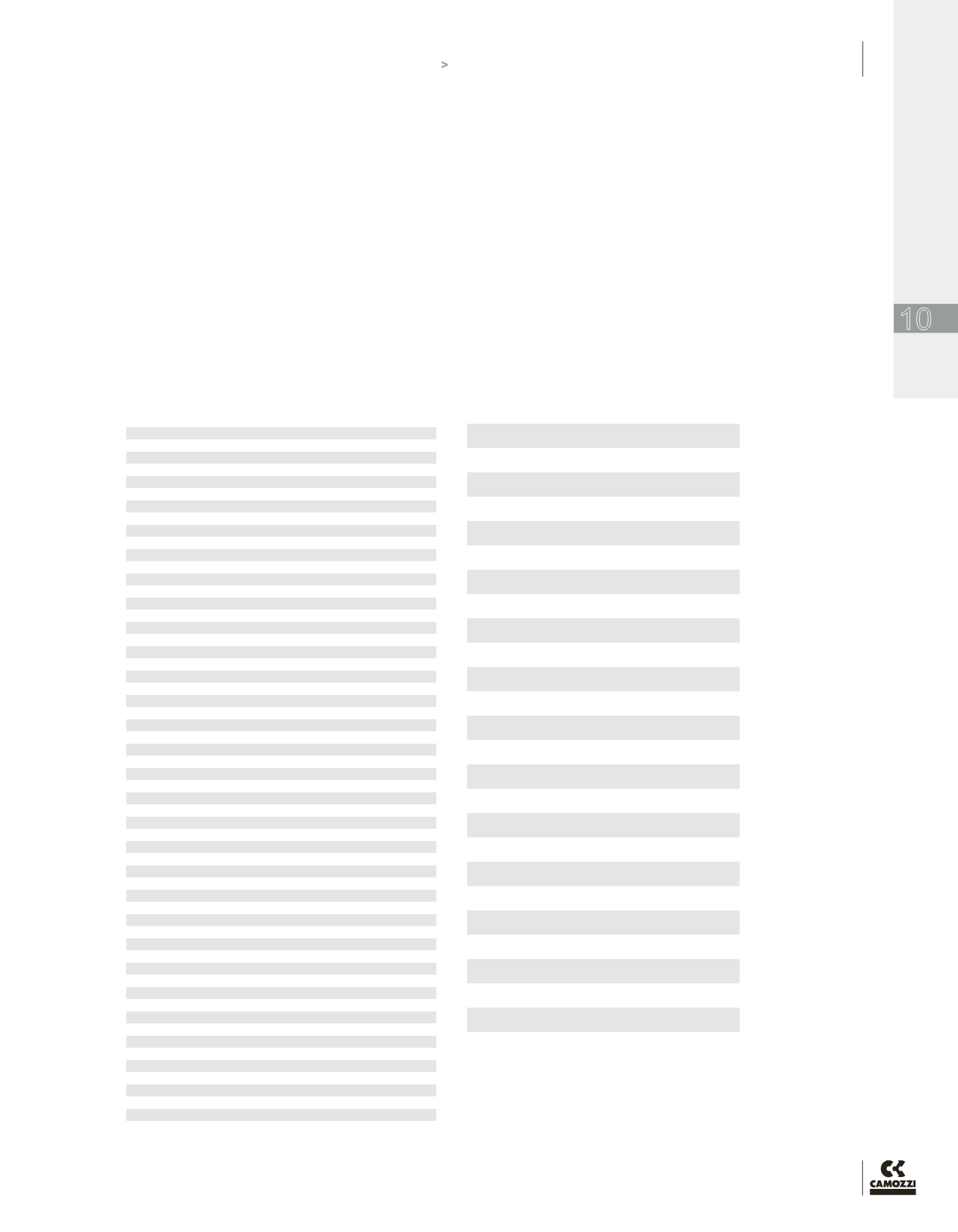

Technical Data

10

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

TECHNICAL DATA

Substance

pH

Value

Test

Volume

(ML)

Test Time

(HRS)

Penetration

(microns/yr)

Apple Juice

3.1

850

1702

1.2

Bean Soup

500

1702

0.7

Canadian Whiskey

5.2

150

3910

1.6

Canned Corn

6.2

250

1702

0.7

Canned Peaches

3.5

400

1681

0.2

Canned Peas

6.1

450

1702

0.2

Canned Pineapple

500

1681

0.3

Canned Potatoes

5.8

350

1681

1.9

Cherry

3.8

150

3910

6.4

Chicken Broth

6

200 312/502

1

(3 tests @ 95 degrees C)

Chocolate Candy

250

1681

Coffee

5.3

700

1729

9.9

Coffee

4.8

200 312/554

4.7

(4 tests @ 95 degrees C)

Cooked Onions

450

1702

0.8

Cranberry Juice

950

1702

0.5

Eggs

8.3

300 1248/1633

0.2

(2 tests @ 2 degrees C)

Gin (2 tests)

7.5

150

3910

0.02

Grape Juice

4

800

1702

1.8

Grapefruit Juice

3.2

900

1702

0.5

Lemon Juice

2.3

800

1702

1

Lemonade

950

1702

11.4

Molasses

350

1702

0.2

Margarine (2 degrees C)

200

1633

Mayonnaise

3.7

470

1681

0.2

Meat Gravy

400

16581

0.6

Milk

6.4

950 1248/1633

0.04

(2 tests @ 2 degrees C)

Mushroom Soup

250

1702

0.3

Mushrooms

150

1681

0.6

Peanut Butter

450

1702

Peeled Tomatoes

4.2

400

1681

0.5

Plum Juice

1000

1702

1

Pork and Beans

5.5

350

1681

0.3

Quark Cheese

300 1248/1633

0.4

(2 tests @ 2 degrees C)

Rum

5.8

150

3910

0.2

Sardines in Soybean Oil

30 (oil)

1681

Scotch Whiskey

5.3

150

3910

1.8

Sliced Radishes

5.2

400

1681

1.8

Sour Kraut

3.5

150

1681

4.4

Spanish Olives

3.7

250

1702

0.3

Tea

2.6

750

1729

4.2

Tea

2.6

200 312/554

9

(4 tests @ 95 degrees C)

Tequila (2 tests)

4.8

150

3910

0.4

Tomato Juice (2 tests)

4.2

710 1321/1336

0.5

Tomato Soup

250

1702

0.5

Tomato Soup

3

200

502

6.1

(2 Tests @ 95 degrees C)

Tropical Punch

950

1702

1.3

Vegetable Oil

470

1729

Vegetable Soup

250

1702

1.2

Vinegar

2.9

470

1729

7

Vodka

8.2

150

3910

Substance

Test

Volume

(ML)

Test Time

(HRS)

Penetration

(microns/yr)

Acacia 1%,

500

5570

0.2

4.4 pH

Acetic Acid,

500

2616

13.7

5% CH3COOH (2 tests)

Alum,

450

1609

4.3

5% (A12S04) 3

Ammonia,

500

3624

12.6

28% NH40H

Asorbic Acid,

500

2660

16.7

10% C4H605

Asorbic Acid,

500

4990

6.6

5% C6H806

Carbon Dioxide,

450

4891

4.3

5% Fenol

Citric Acid,

500

2660

14.7

5% C6H807

Deionized Water,

200

211

(2 tests @ 95 degrees C)

Deionized Water,

900 4536/5089

1.9

(1MQ-cm% tests)

Dextrine,

500

5570

0.1

1%, 3.8 pH

Drinkable Water,

900 4536/5089

0.05

8.0 pH (4 tests)

Fecula,

500

3839

0.5

1%

Lactic Acid,

500

1337

1.3

85% C3H603

Phosphoric Acid,

450 2599/2618

12.6

1% H3P04 (2 tests)

Potassium Carbonate, 450 2302

0.2

25% K2C02

Saline Water,

450 1337/3478

2

26% NaCl (2 tests)

Saline Water,

450 1198/3335

0.1

40% CaCl2 (2 tests)

Salt,

450

1198

0.5

5% NaCl, 6.3 pH

Sea Water,

500

1272

1

Artifical, 8.2 pH (2 tests)

Sodium Bicarbonate,

500

3839

6.4

2% NaHC03

Sodium Hyroxide,

500

5042

0.2

1% NaOH

Sodium Hypochlorite,

450

460

0.5

1% NaOCL

Sodium Nitrate,

450

574

12

42% NaNO2

Sodium Nitrate,

450

1198

47% NaNO3

Water,

450

404

7.9

700mg/1CO2, 3.9 pH (2 tests)

LEGEND:

• Very satisfactory result, rate of removal from corrosion less than 2.5 microns per year.

• Useful result, rate of removal from corrosion less than 12.5 microns per year.

• To be decided in each case individually, rate of removal from corrosion less than 25 microns

per year.

• Application not recommended for long periods, rate of removal from corrosion more than 25

microns per year.

Corrosion Resistance of Electrolytic Nickel Plating

for Foods

Camozzi fittings

are plated at a

thickness of 5-8

µm (microns).