232

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

TECHNICAL DATA

Technical Data

10

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

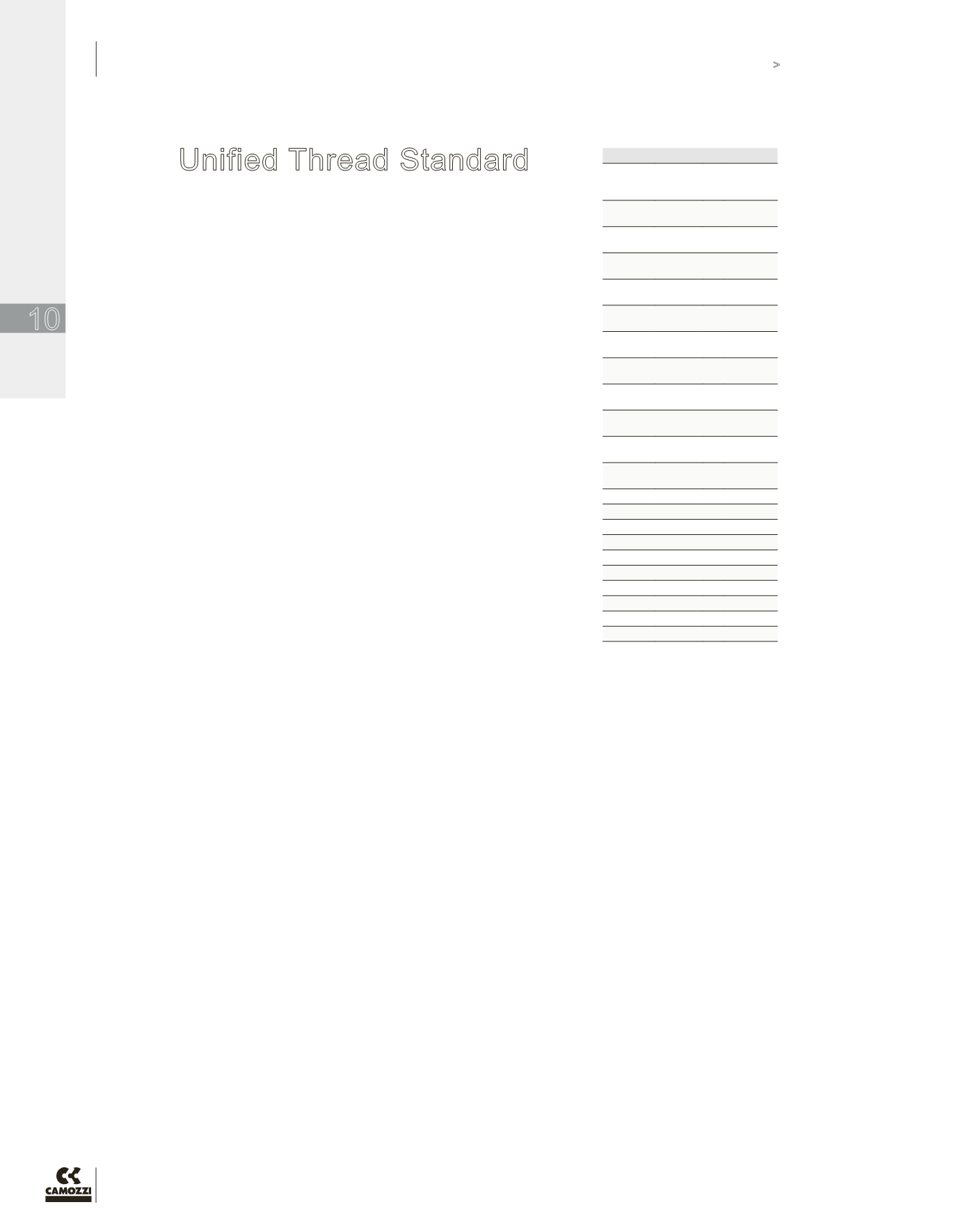

UTS PREFERRED SIZES

Major

diameter

[in]

Pitch

[1/in]

Major

diameter

[mm]

Coarse

UNC

Fine

UNF

#0 =

0.0600

–

80 1.5240

#1 =

0.0730

64 72 1.8542

#2 =

0.0860

56 64 2.1844

#3 =

0.0990

48 56 2.5146

#4 =

0.1120

40 48 2.8448

#5 =

0.1250

40 44 3.1750

#6 =

0.1380

32 40 3.5052

#8 =

0.1640

32 36 4.1656

#10 =

0.1900

24 32 4.8260

#12 =

0.2160

24 28 5.4864

1/4

20 28 6.3500

5/16

18 24 7.9375

3/8

16 24 9.5250

7/16

14 20 11.1125

1/2

13 20 12.7000

9/16

12 18 14.2875

5/8

11 18 15.8750

3/4

10 16 19.0500

7/8

9

14 22.2250

1

8

12 25.4000

Tolerance classes

A classification system exists for ease of manufacture and interchangeability of fabricated threaded

items. Most (but certainly not all) threaded items are made to a classification standard called the

Unified Screw Thread Standard Series. This system is analogous to the fits used with assembled

parts.

Classes 1A, 2A, 3A

apply to external threads; Classes 1B, 2B, 3B apply to internal threads.

Class 1

threads are loosely fitting threads intended for ease of assembly or use in a dirty environ-

ment.

Class 2

threads are the most common. They are designed to maximize strength considering typi-

cal machine shop capability and machine practice.

Class 3

threads are used for closer tolerances.

Thread class

refers to the acceptable range of pitch diameter for any given thread. The pitch

diameter is shown as d2 in figure 1 above. There are several methods that are used to measure

the pitch diameter. The most common method used in production is by way of a Go-NoGo gauge.

References

ASME/ANSI B1.1 – 2003 Unified Inch Screw Threads, UN & UNR Thread Form

ASME/ANSI B1.10M – 2004 Unified Miniature Screw Threads

ASME/ANSI B1.15 – 1995 Unified Inch Screw Threads, UNJ Thread Form

Unified Thread Standard

The Unified Thread Standard (UTS)

defines a standard thread

form and series—along with allowances, tolerances, and desig-

nations—for screw threads commonly used in the United States

and Canada. It has the same 60° profile as the ISO metric screw

thread used in the rest of the world, but the characteristic dimen-

sions of each UTS thread (outer diameter and pitch) were cho-

sen as an inch fraction rather than a round millimeter value. The

UTS is currently controlled by ASME/ANSI in the United States.

Designation

The standard designation for a UTS thread is a number indicat-

ing the nominal (major) diameter of the thread, followed by the

pitch measured in threads per inch. For diameters smaller than

¼ inch, an integer number defined in the standard indicates the

diameter. For all other diameters, the inch figure is given.

This number pair is optionally followed by the letters UNC and

UNF if the diameter-pitch combination is from the “coarse" or

“fine" series, and may also be followed by a tolerance class.

Example:

6-32 UNC 2B (major diameter: 0.1380 inch, pitch:

32 tpi)