234

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

TECHNICAL DATA

Technical Data

10

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

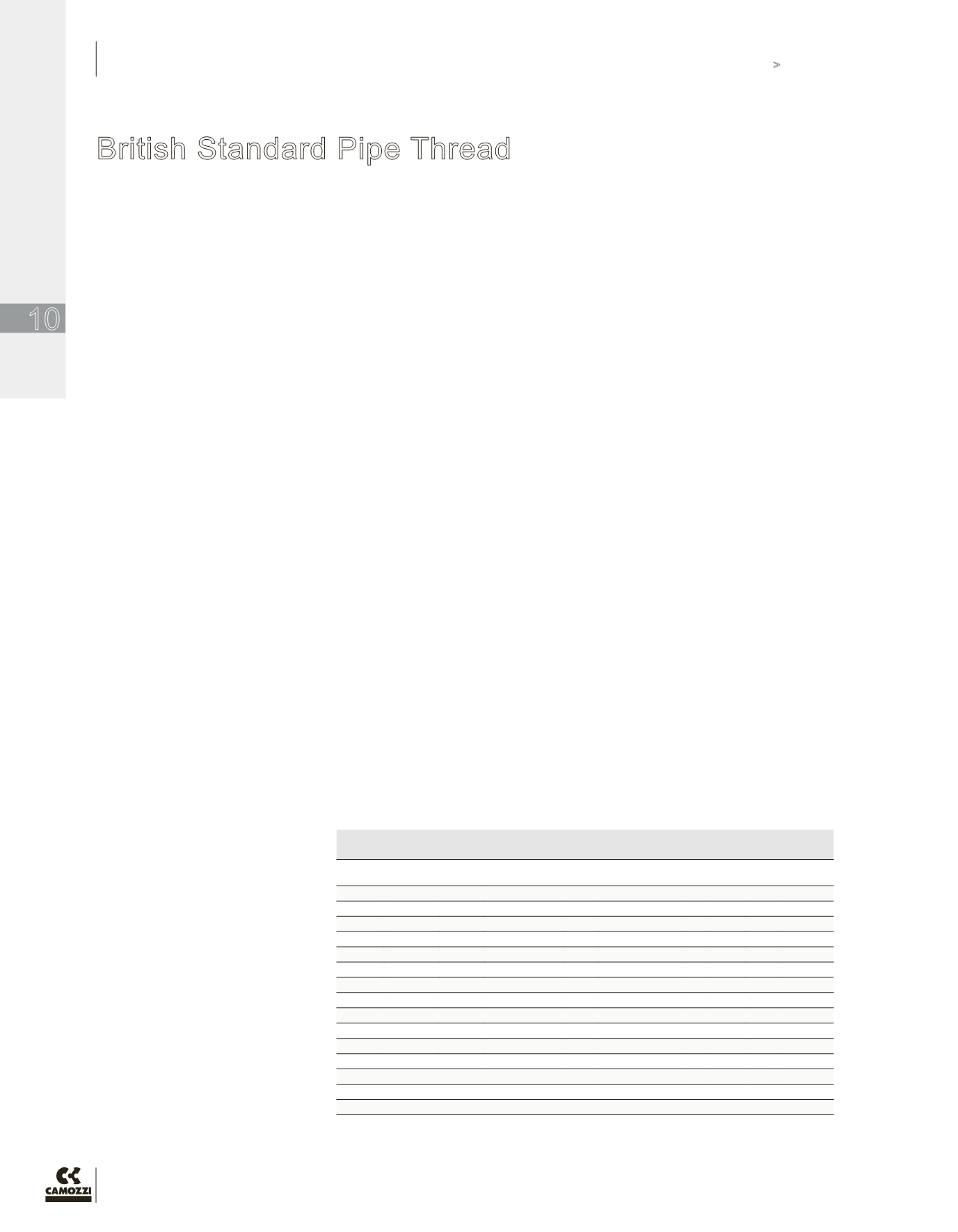

Thread

Size

Threads

Per Inch

Pitch Major Diameter of the

Thread

Gauge Length

Corresponding Pipe

[mm]

[mm]

[in]

[mm]

DN OD

[mm]

OD

[in]

Thickness

[mm]

1/16

28

0.907

7.723

0.304

4

1/8

28

0.907

9.728

0.383

4

6 10.2 0.40

2

1/4

19

1.337

13.157

0.518

6

8 13.5 0.53

2.3

3/8

19

1.337

16.662

0.656

6.4

10 17.2 0.68

2.3

1/2

14

1.814

20.995

0.825

8.2

15 21.3 0.84

2.6

3/4

14

1.814

26.441

1.041

9.5

20 26.9 1.06

2.6

1

11

2.309

33.249

1.309

10.4

25 33.7 1.33

3.2

1¼

11

2.309

41.910

1.650

12.7

32 42.4 1.67

3.2

1½

11

2.309

47.803

1.882

12.7

40 48.3 1.90

3.2

2

11

2.309

59.614

2.347

15.9

50 60.3 2.37

3.6

2½

11

2.309

75.184

2.960

17.5

65 76.1 3.00

3.6

3

11

2.309

87.884

3.460

20.6

80 88.9 3.50

4

4

11

2.309

113.030

4.450

25.5

100 114.3 4.50

4.5

5

11

2.309

138.430

5.450

28.6

125 139.7 5.50

5

6

11

2.309

163.830

6.450

28.6

150 165.1 6.50

5

British Standard Pipe Thread

The British Standard Pipe thread (BSP thread) is a family of standard screw thread types that has been

adopted internationally for interconnecting and sealing pipe ends by mating an external (male) with an

internal (female) thread.

Types

Two types of threads are distinguished:

• Parallel threads, which have a constant diameter. (G)

• Taper threads, whose diameter increases or decreases

along the length of the thread. (R)

They can be combined into two types of joints:

• Jointing threads: These are pipe threads for joints made

pressure-tight by the mating of the threads. They always

use a taper external thread, but can have either parallel or

taper internal threads. (In Continental Europe, taper inter-

nal pipe threads are not commonly used.)

• Longscrew threads: These are parallel pipe threads used

where a pressure-tight joint is achieved by the compression

of a soft material (gasket) on to the surface of the external

thread by tightening a backnut against a socket.

Threadform

For both the taper and the parallel pipe threads, the

Whitworth thread form is used, which has the following char-

acteristics:

• symmetrical V-thread in which the angle between the

flanks is 55° (measured in an axial plane)

• one-sixth of this sharp V is truncated at the top and the

bottom

• the threads are rounded equally at crests and roots by cir-

cular arclend tangentially with the flanks

• the theoretical depth of the thread is therefore 0.64times

the nominal pitch the relation between

Pipe thread sizes

The major diameter listed is the

outer diameter of the external

thread. For a taper thread, it

is the diameter at the ”gauge

length” from the small end of

the thread. The taper is “1 to

16”, meaning that for each 16

mm increase in the distance

from the end, the diameter

increases by 1 mm.

A list of 15 thread sizes is defined by the standards,

ranging from 1/16 to 6. The size number was originally

based on the inner diameter measured in inches

(25.4 mm) of a steel tube for which the thread was

intended, but is in the modern metric version of the

standard simply a size number.

Pipe thread designations

These standard pipe threads are formally referred to by

the following sequence of blocks:

• the words “Pipe thread”,

• the document number of the standard (e.g., ”ISO 7”

or ”EN 10226”)

• the symbol for the pipe thread type:

G = external+internal parallel (ISO 228)

R = external taper (ISO 7)

Rp = internal parallel (ISO 7)

Rc = internal taper (ISO 7)

• the thread size

Threads are normally right-hand. For left-hand threads,

the letters ”LH” are appended.