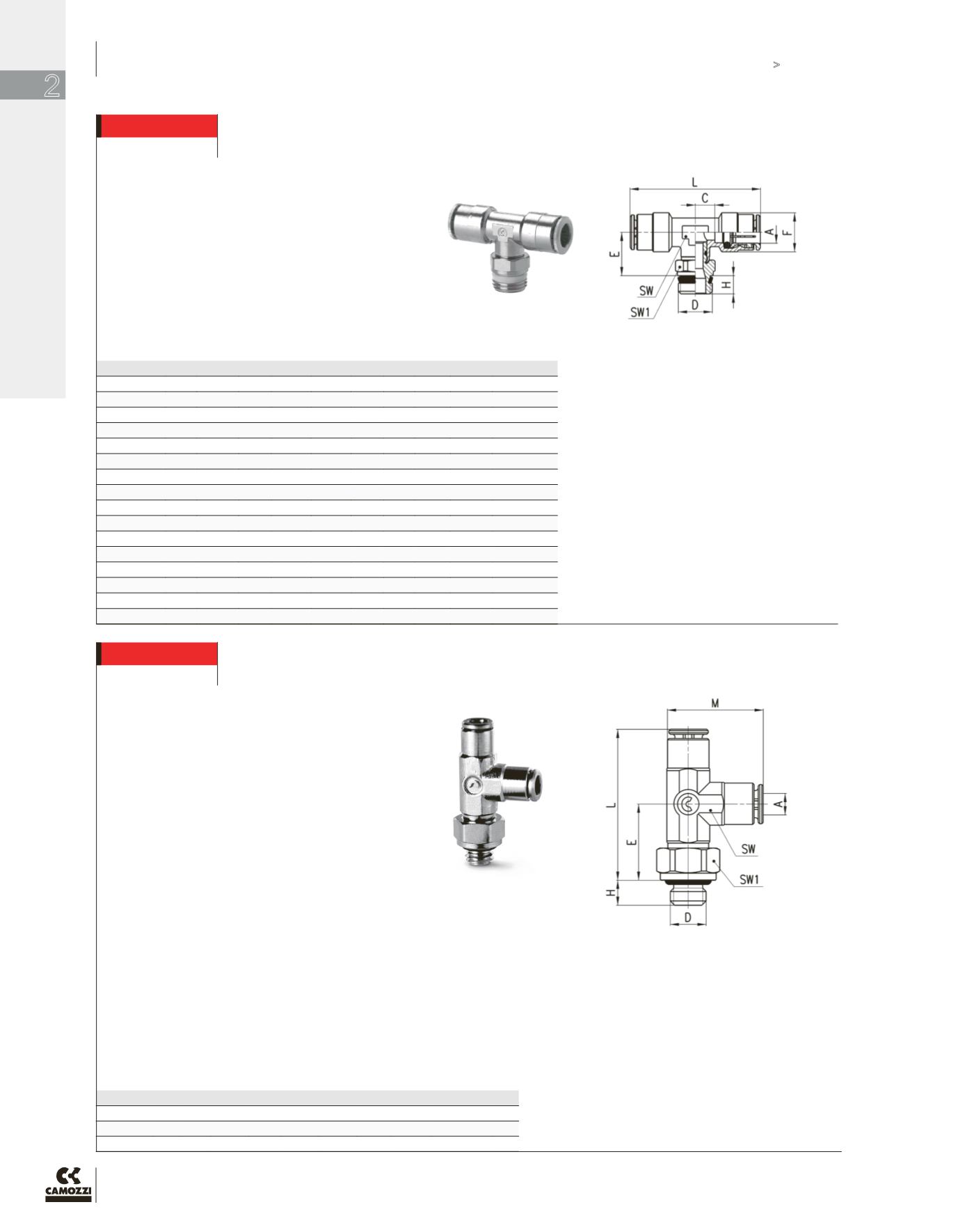

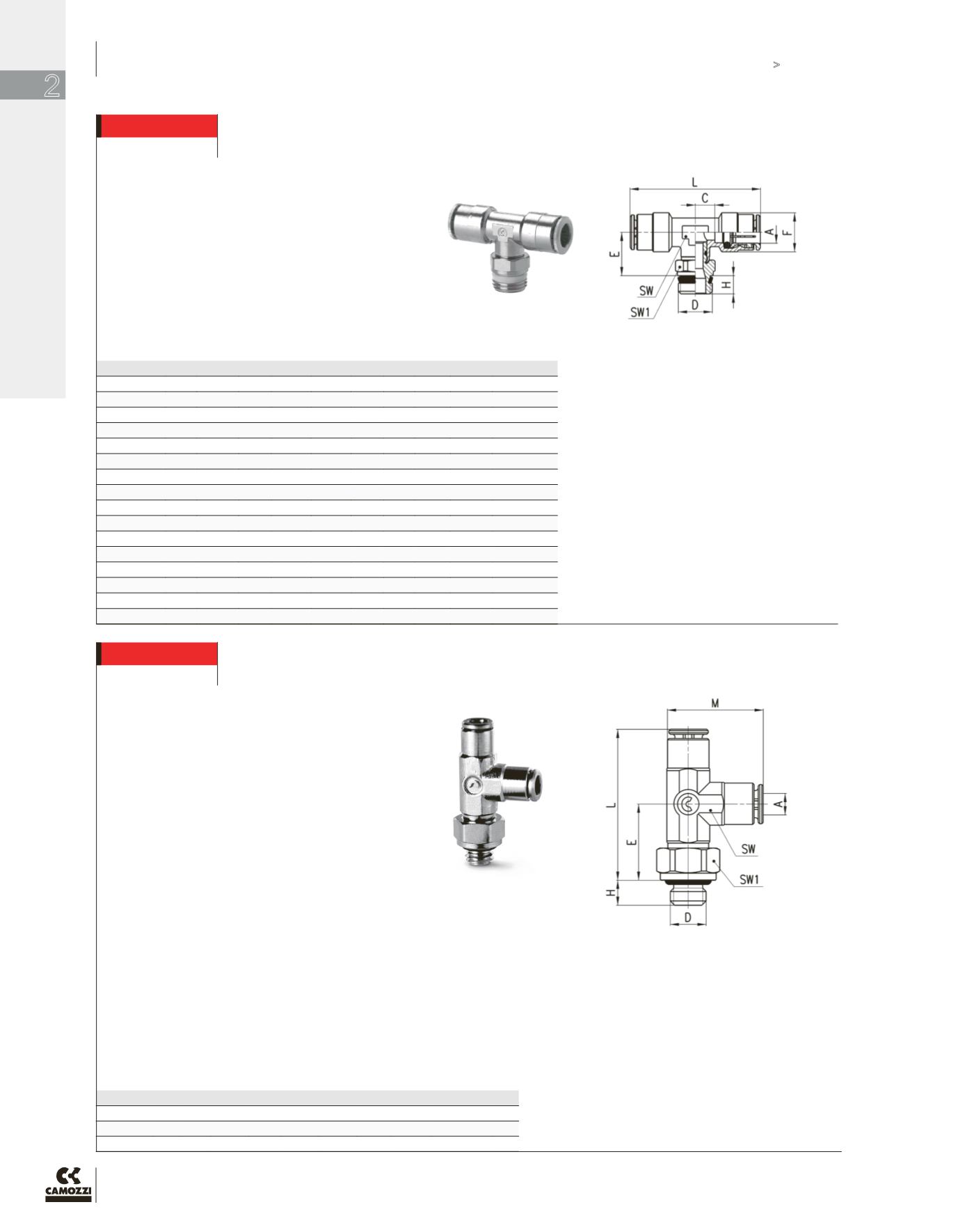

Composite Fittings:

BSP Threads with Spot-Face O-Ring Seal

The technical solution:

Camozzi has maintained the technically advanced and world-renowned collet solution by further

optimizing the dimensions and the design from Series 6000 Fittings and Flow Control Valves.

Durable Metal Collet:

Nickel-Plated brass collet provides superior

resistance to shock, wear and fatigue compared to inferior plastic col-

lets. Proven metal design offers a higher holding force with easier tube

release that won’t scratch tubing like plastic “bite-ring” designs. Tube

OD size is stamped on collet face.

Composite Body:

Glass-fiber reinforced, thermoplastic material is

incredibly strong and lightweight with improved resistance to UV expo-

sure, abrasion and other chemical substances. Molded composite mate-

rial allows for integral mounting holes and a broader range of complex

shapes.

Spot-Face O-Ring Thread Seal Design:

Reusable Buna-N seal

reduces assembly time by up to 45% and eliminates exposed threads,

making it ideal for food processing, robotics, packaging & manifold

assemblies. Eliminates risk of pneumatic system contamination from

antiquated thread sealants.

Features

Collet

•

Nickel-Plated, All-metal Collet and Release ring

•

Brass insert for collet support and tube grip strength

•

Collet design offers greater grip strength under higher pressure or

tubing tension

•

Collet release mechanism based on relaxed slope of grip teeth, as

opposed to disengaging “bite-rings” from partially cut tubes

•

Removable Collet and tube o-rings

Body

•

Glass-fiber reinforced, thermoplastic compact injection-molded

body

•

All-Metal, Nickel-Plated Threads

•

Standard Buna-N or Specialized O-ring choices for High-Temp,

Low-Temp, Special Fluids, Food-Grade compatibility

•

Broad Range of shapes and configurations

•

Crimp design on Swivels maintains Full ID Flow path

•

Swivels offer Mechanical crimping lock based on brass design

Thread Design

•

Multiple Thread sealant systems: Pro-Fit/NPTF & BSP/O-Ring

Spot Face

•

Full ID Flow for Swivels with high relief on larger sizes

•

Swivels supported on two surfaces for stability and support of

captured swivel o-ring seal

Benefits

Collet

•

Won’t break like plastic release rings, More Durable design

•

Brass insert maintains collet stability, tube grip strength and consis-

tent tube-release performance

•

Higher holding force, with easier release

•

Won’t scratch tubes like “bite-ring” designs

•

Less chance of micro-leakage and bubble-leaks over time due to dam-

aged tubing

•

Higher pressures actually offer greater grip-strength with high-pressure

Nylon tubing

•

OD Tube Size stamped on Collet face

Body

•

Thermoplastic Nylon composite more resistant to UV exposure

•

Better resistance to stress-cracking, abrasion, solvents, detergents &

hydrocarbons

• 15%

Reduction in overall Body size, (24% in Assembly height / 8%

in Tube Radius), compared to recently reduced-size Brass line

Spot-Face O-Ring Thread Design

•

Reduced assembly time without taping of threads

•

Re-usable seal design, with no exposed threads

•

FDA/NSF approved materials

•

Simplified manifold circuits with broader variety of fitting combina-

tions and shapes to select

•

Lighter weight for End-of-Arm tooling & Robotic handling

•

Compact design reduces overall dimensions for valve assemblies,

packaging applications and control cabinets

Metal Collet

Metal Collet

Insert

Spot-Face Seal

Composite Body

Metal

Thread

O-Ring

Seal

B S P / M E T R I C

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

65

F I T T I N G S

2

compos i t e F I T T I NGS