VALVES

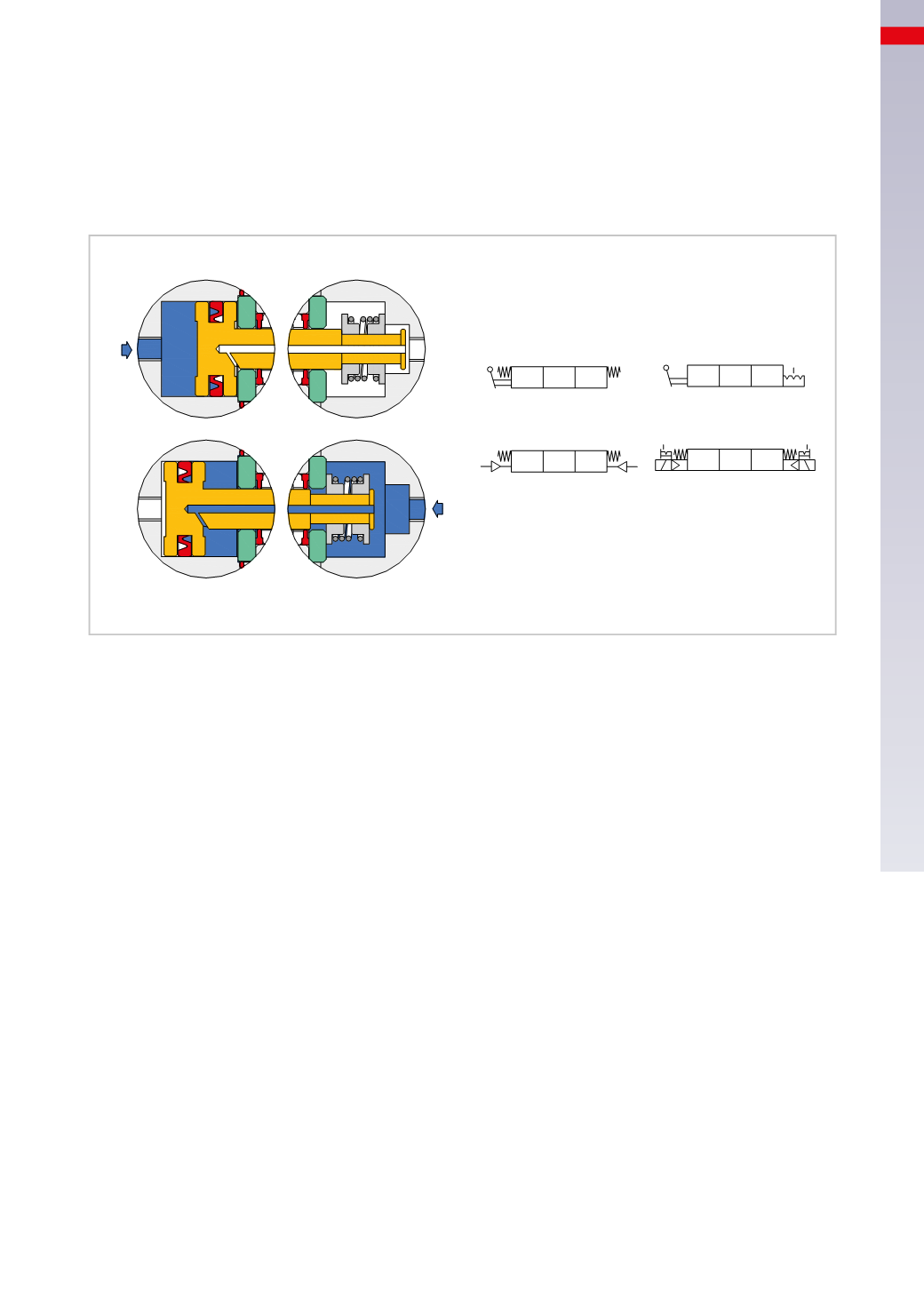

Figure 43

Operation valves 5/3

The command coming from

A

acts on the left side of the pilot piston, moving the spool to the right, changing the

direction of passage of the compressed air and compressing the return spring. Once the command is interrupted,

the spring repositions the spool, which returns to the center position. The command coming from

B

passes through

the hole in the spool, it reaches the left side of the pilot piston moving it to the left, compressing the repositioning

spring. After removing the command, the spring repositions the spool to the central position.

The 5/3 CO valves and 5/3 CP valves may be replaced by a double 3/2 NC and 3/2 NO valve.

A

B

Fig. 43

Blocking valves

One of the functions required of pneumatic cylinders is the ability to stop the cylinder during both its positive and/

or negative stroke. As we have seen, this function can be achieved with a 5/3-way closed centers (CC) valve, which

closes both the supply inlet and valve exhaust. This function can also be obtained with blocking valves, which can

be mounted directly on the cylinder ports. These valves, if appropriately mounted, offer similar results but with

a higher degree of safety. The 5/3-way CC valve is subject to possible leakage over the spool seals, or between

the fittings and tubes that could compromise the function of the CC valve. The blocking valves, being mountable

directly on the cylinder ports, are not affected by problems on the tubes or fittings; having no intermediate

connections they are less prone to leaks.

The function of the blocking valves is to interrupt the exhaust and air supply to the cylinders.

Blocking valves are categorised into two types:

unidirectional

and

bidirectional

.

Unidirectional blocking valves

Figure 44

Pos. A

:

the valve is in rest position, with no pilot signal.

Outlet 2 of the valve is mounted directly on the cylinder. The exhaust air from the chamber of the cylinder enters

the blocking valve, which, in this state, is closed. This condition is generated by the effect of the spring and the

pressure from the compressed air inside the cylinder acting on the plunger pushing it upwards, favouring the closure.

The plunger acts as a unidirectional valve as it allows for the passage in one direction.

Pos. B

:

the valve is in rest position with no pilot signal; C/A is connected through inlet 1.

The C/A from the main valve enters the blocking valve through inlet 1 and exits from outlet 2 which, being

connected to the cylinder chamber, allows the C/A to fill it. The passage from inlet 1 to outlet 2 is open because

the pressure of the C/A from input 1 is sufficient to open the plunger.

Pos. C

:

presence of pilot signal, the valve is in exhaust position.

The C/A exiting the exhaust chamber of the cylinder enters the blocking valve through outlet 2, passes the depressed

plunger, exits from inlet 1 and continues on to the main valve where it can be exhausted. To achieve the transition

from outlet 2 to inlet 1, it is necessary to actuate the pilot piston of the blocking valve through the pilot signal 21.

The pilot signal 21, acting on the control piston, moves the unidirectional poppet downwards and opens it.

4

111

CAMOZZI

>

VALVES