VALVES

1

1

2

2

12

12

REST

ACTUATED

A

B

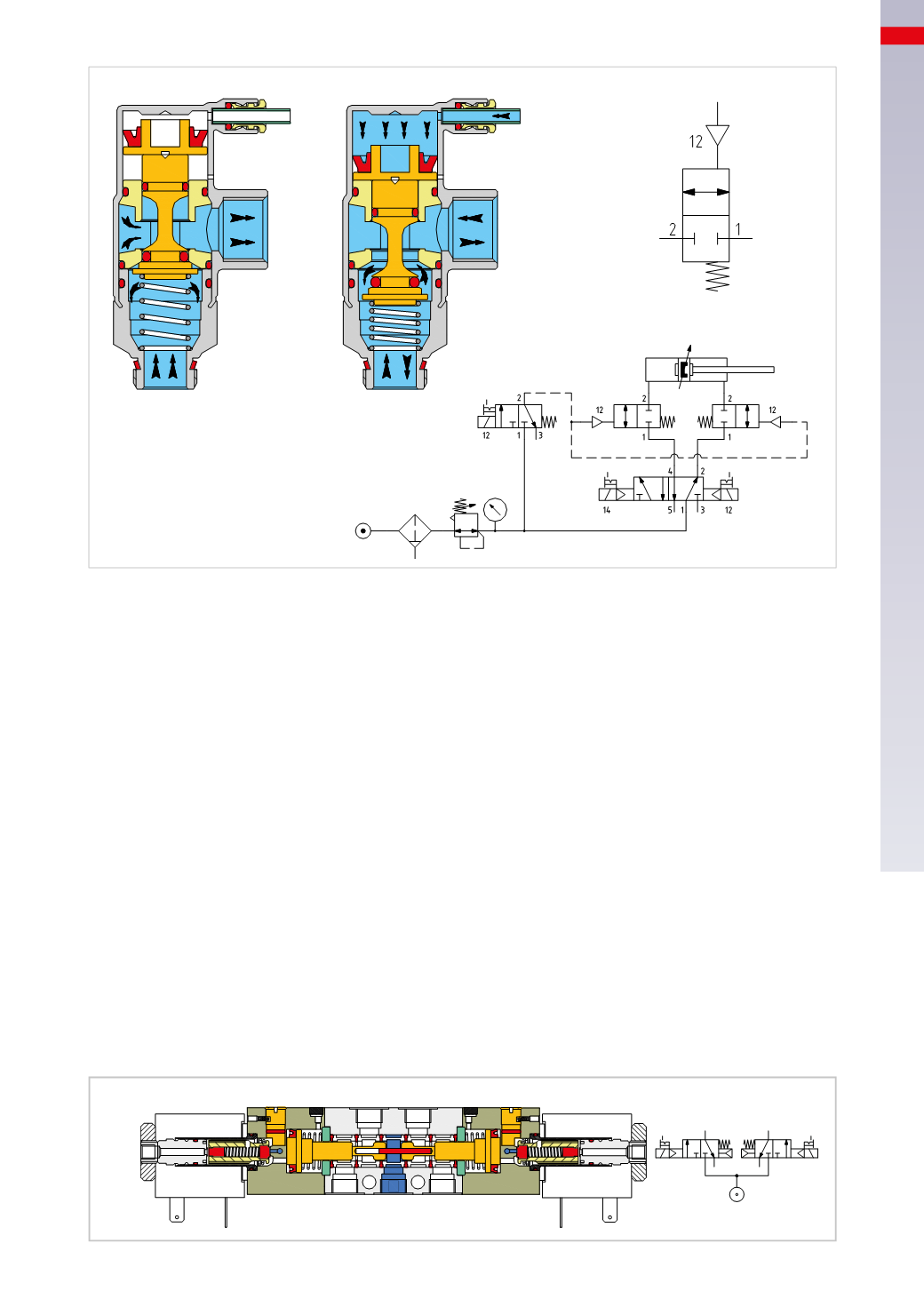

Fig. 45

Double 2/2-way and 3/2-way valves

Optimising space is often an important aspect for machine designers and as a consequence, reducing the overall

dimensions for each function is an important parameter for the valve manufacturer to consider. To optimize the

dimensions of valve blocks/valve islands, it is possible to integrate two 2/2-way or 3/2-way spools in one valve

body. In this way the overall dimensions are not those of two individual valves side by side, but those of a bistable

valve. Each 2 x 3/2-way or 2 x 2/2-way can comprise:

• two NC valves

• two NO valves

• one NO valve and one NC valve

Each valve, which is a part of the double 2/2-way or 3/2-way valve, is independent from the other and has its own

pilot signal, which can be pneumatic or electric.

Figure 46

2 x 3/2-way NC valve electrically operated

In the body of the double valve there are two spools with a 3/2-way NC function with return springs and two

sets of electric pilot signals. In the absence of pilot signals 12 and 14 (rest position) the channels from inlet 1

to outlets 2 and 4 are closed. With the pilot signal 12, the spool on the right side moves to the left, opening the

passage of compressed air from inlet 1 to outlet 2, when the pilot signal is interrupted, the spring repositions the

spool closing inlet 1, and connects outlet 2 to exhaust 3. With pilot signal 14, the spool on the left side moves to

the right, opening the passage of compressed air from inlet 1 to outlet 4, when the pilot signal is interrupted, the

spring repositions the spool closing inlet 1 and connects outlet 4 with exhaust 5. With the two pilot signals 12 and

14 activated simultaneously, the passages from inlet 1 to outlets 2 and 4 are open; in this case the airflow rate is

reduced, as both outlets are open simultaneously.

1

4

5

3 1

2

14

12

14

12

1

5

3

2

4

Fig. 46

4

113

CAMOZZI

>

VALVES