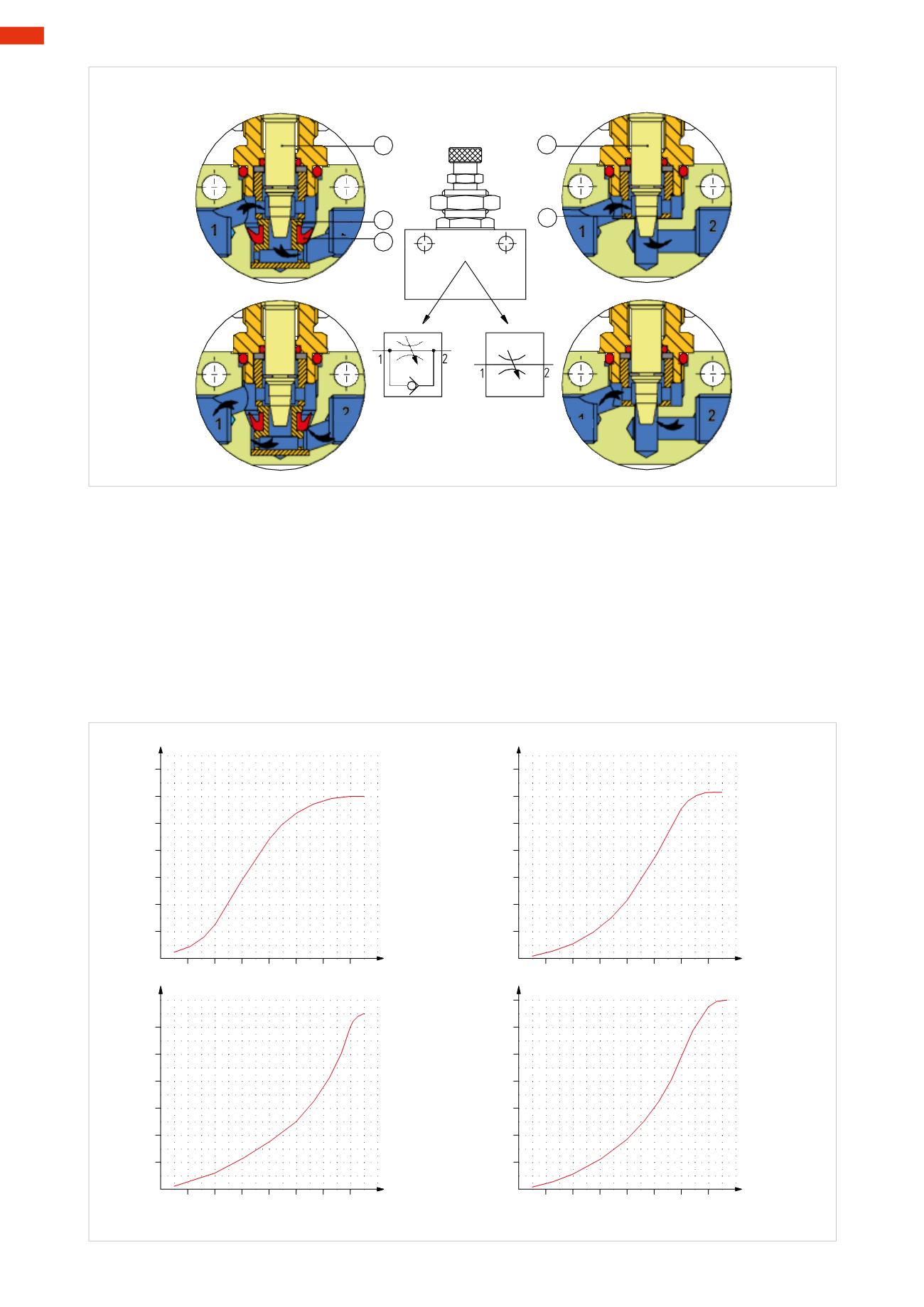

Unidirectional

Bidirectional

A

C

B

D

A

A

B

C

D

1

2

1

2

1

2

1

2

Fig. 61

Figure 62

To select the correct dimensions of the flow regulator, it is advisable to consider the following:

• The value of themaximum flow ratewith the adjusting screw fully open.

•The flow rate in the non adjustable direction: a certain amount of compressed airmust reach the thrust chamber

of the cylinder to ensure constant pressure. During the movement of the cylinder, the volume of the thrust

chamber continually changes and the amount of compressed air enteringmust always be able to compensate

for this volume change, otherwise themovement would be erratic.

• The gradient of the curve indicates the flow rate based on the number of turns of the adjusting screw:

the volume of compressed air within the chambers of the cylinder depends on the diameter, the stroke and the

supplied pressure. Referring to graphs illustrating the flow characteristics, allows for the selection of the most

appropriate flow regulator that enables themost optimal and precise adjustment..

0 2 4 6 8 10 12 14

200

400

600

800

1000

1200

0 2 4 6 8 10 12 14

20

40

60

80

100

120

1400

0 2 4 6 8 10 12 14

100

200

300

400

500

600

0 2 4 6 8 10 12 14

65

130

195

260

325

390

455

140

N° turns

adjusting screw

N° turns

adjusting screw

N° turns

adjusting screw

N° turns

adjusting screw

Qn

Nl/min.

Qn

Nl/min.

Ø 4mm

Ø 6mm

Ø 8mm

Ø 10mm

800

Fig. 62

4

126

CAMOZZI

>

VALVES