VALVES

Figure 57

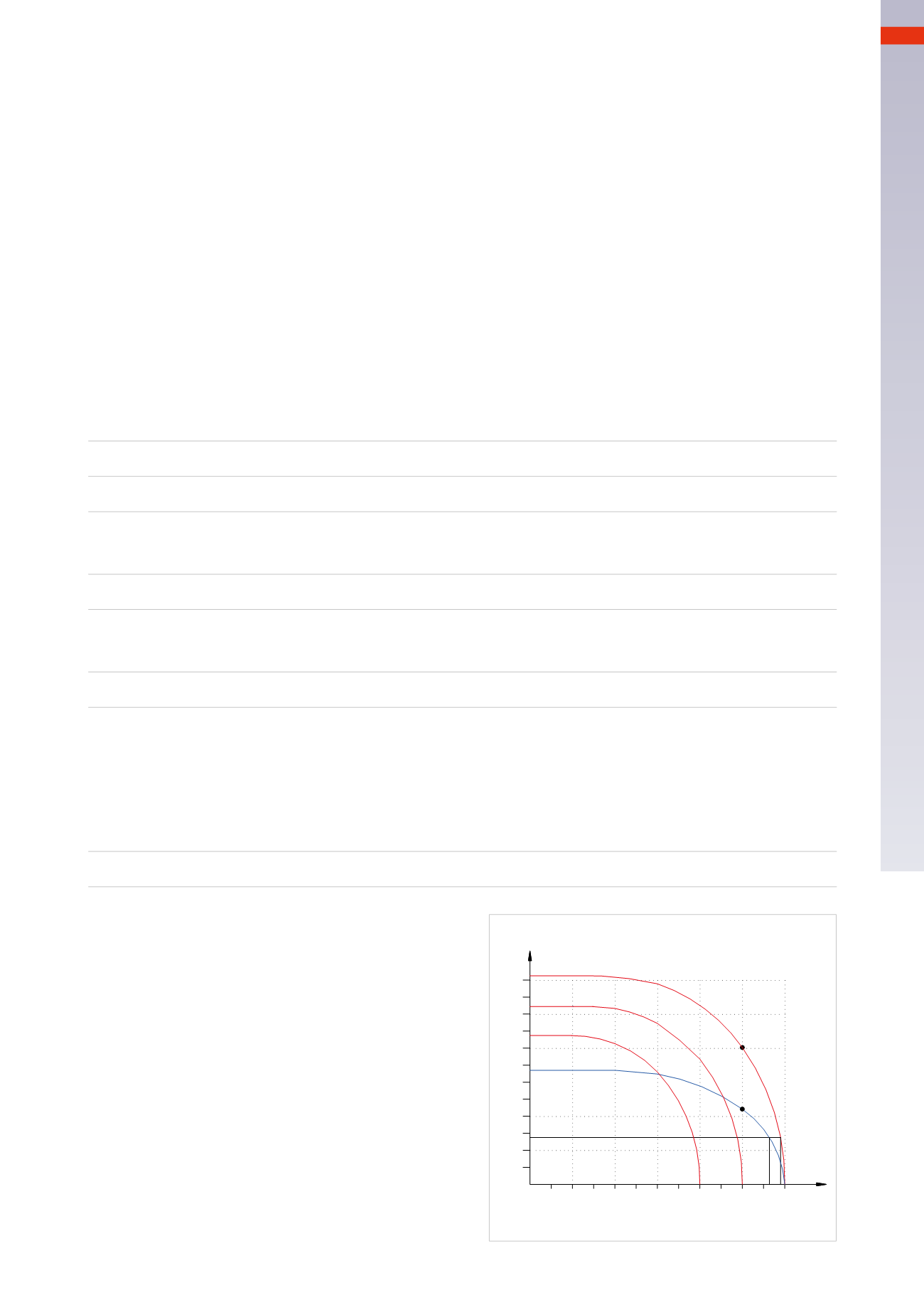

From the graph it is possible to detect the flow

characteristics of two different valves which have M5

and M7 threads respectively.

The required flow rate

Q

r

can be obtained from both

valves, which have a limited pressure drop (

∆

p

)

which varies from 0.1 to 0,4

bar

.

Despite having a cylinder of fixed dimensions as in

this case, it is not necessary to size the valve in relation

to the connection on the heads, but it is possible to

use valves with the best price/size/flow ratio.

Sizing of directional control distribution valves

and connecting tubes

In a pneumatic system a cylinder must move a given load and this must be executed within a designated time.

The first requirement has been addressed in the previous chapters; we now analyze the latter requirement.

The following data must first be determined:

• The volume to fill, for example the cylinder chamber used.

• The time required to complete the stroke.

• The operating pressure.

Valve sizing

Assume we have a cylinder with the following characteristics:

diameter

D

= 50

mm

,

stroke length

c

= 250

mm

stroke,

operating pressure

P

= 6

bar,

timing of the positive stroke

t

= 1,5

sec

.

Calculation of the volume

V

of the cylinder:

V

= Area * Stroke

V

=

r

2

*

π

*

c

V

= (25

[mm])

2

*

π

* 250

[mm]

V

= 490.625

mm

3

V

=

0,49

dm

3

Calculation of the amount of required air

Q

s

to fill the volume

V

at a pressure of 6

bar

in a time

t

= 1,5

sec.

Q

s

=

V

*

P

abs

Q

s

= 0,49

[dm

3

]

*

7

[bar]

Q

s

=

3,43

Nl

This amount should be provided in a time

t

= 1,5

sec

, which expressed in

Q

r

(per minute) becomes:

Q

r

=

(Q

s

/

t

) *

60

Q

r

= (3,43 / 1,5)

*

60

Q

r

=

137

Nl

/

min

The quantity of air required for the valve to move a cylinder:

of diameter

D

= 50

mm

stroke

c

= 250

mm

in a time

t

= 1,5

sec.

is

137

Nl

/

min

Nl/min.

0 0,5 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6

100

200

300

400

500

600

Flow curve of the valve

with Qn =

220

and

400

Nl/min

137

Qn

Bar

Qn

Fig. 57

4

121

CAMOZZI

>

VALVES