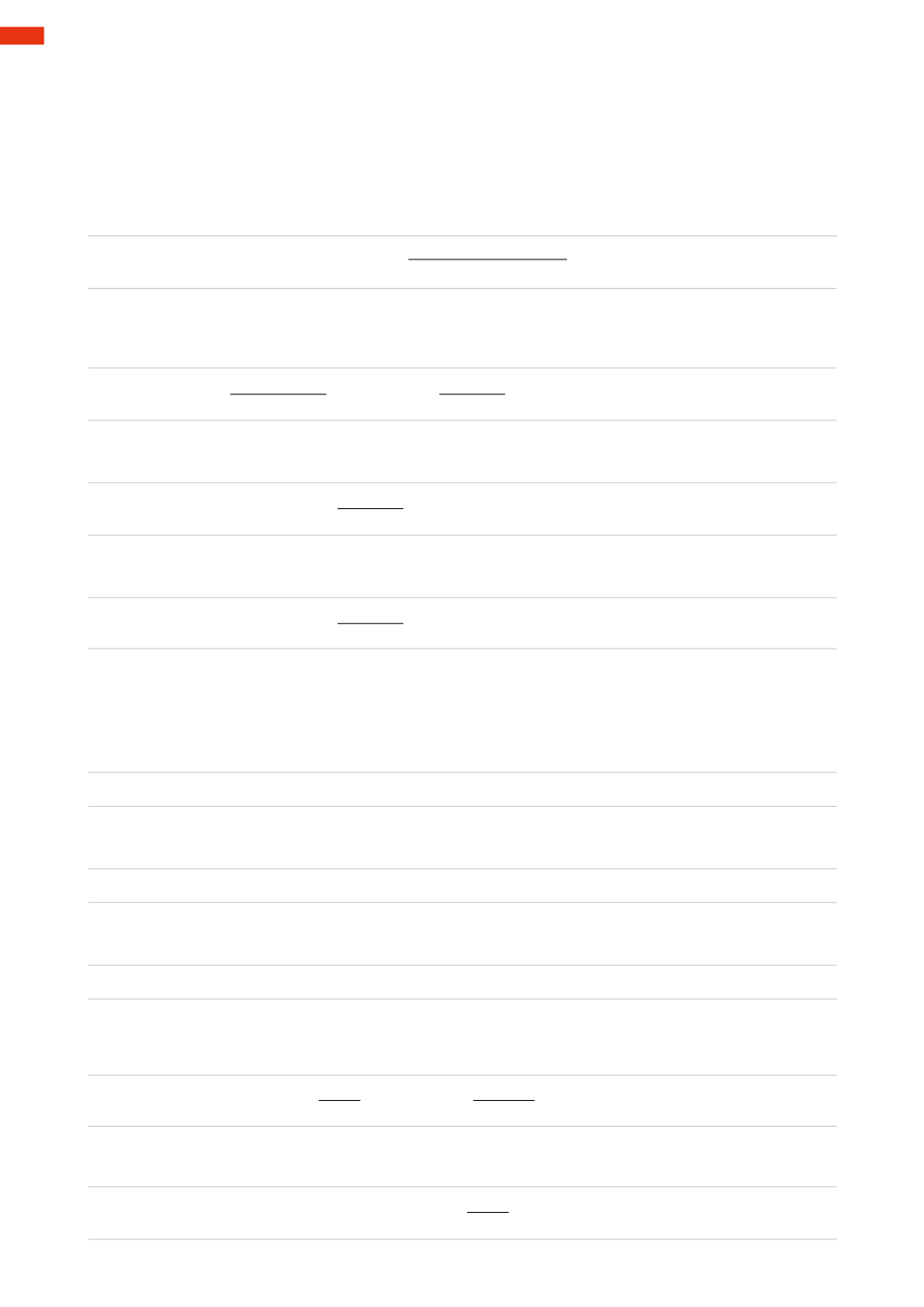

Figure 58

Tube Sizing

For the selection of the tubes it is necessary to check the flow characteristics according to their length and

diameter (see

Fig. 58

). Incorrect sizing will consequentially increase

∆

p

with repercussions on travel time of the

cylinders, and therefore on the cycle. When several components are aligned in sequence, the resulting flow rate

is not of the component with the lowest value. To calculate the value it is necessary to introduce a new variable

called “

conductance

”.

The conductance is the ratio between the flow rate value in free flowQ and the value of the absolute pressure

.

C

=

Q [Nl

/

min]

P

rel

[bar]

+

P

atm

[bar]

Taking as reference the valve with

Q

n

≅

400

Nl

/

min

we see that the value of flow in free air at 6

bar

is

Q

≅

610

Nl

/

min

, fromwhich the conductance is equal to:

C

=

Q

C

=

610

C

=

87,14

Nl / min * bar

P

rel

+

P

atm

6+1

If the supply pressurewere 5

bar

:

C

=

520

C

=

87,14

Nl / min * bar

5+ 1

If the supply pressurewere 4

bar

:

C

=

435

C

=

87,14

Nl / min * bar

4+ 1

We conclude that the value of conductance does not vary by changing the supply pressure.

Generally in catalogues, the nominal flow rate

Q

n

is indicated, calculated according toUNI ISO8778with a supply

pressure of 6

bar

and

∆

p

1

bar.

Taking the measured values on the graph, we observe that the free air delivery

with a supply pressure of 6

bar

is:

Q

≅

610

Nl

/

min

The conductance of this valve as in previous calculations is:

C

=

87,14

Nl

/

min

*

bar

Also from the graphwe observe that with a supply pressure of 6

bar

and

∆

p

1

bar

the flow rate is:

Q

n

≅

400

Nl

/

min

Taking the value of

Q

n

and dividing it by the value of

C

we obtain a coefficient

X

that experimental tests have

determinedwith good approximation, to be valid for all the sections traversed by a fluid.

X

=

Q

n

X

=

400

X

≅

4,6

C

87,14

Another way to calculate the conductance of an element is:

C

=

Q

n

X

4

122

CAMOZZI

>

VALVES