VALVES

Time

Time

Pressure

Pressure

t

1

t

2

t

1

t

2

1

2

2

3

1

3

1

2

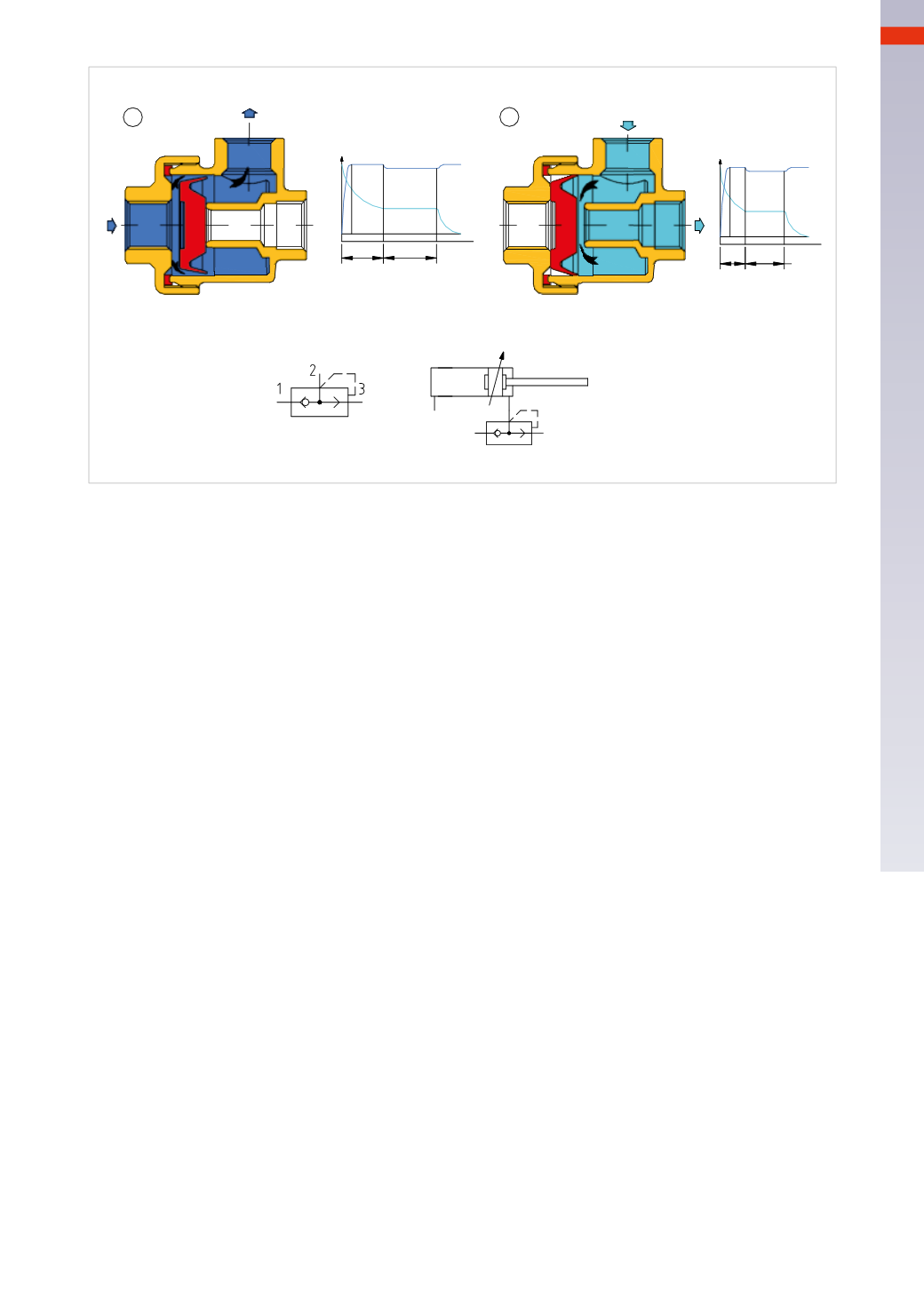

Fig. 60

Thediagrams show thedifferent behavior of theC/A in the two chambers of adoubleacting cylinder in thepresence

or absence of a quick exhaust valve.

The value

t

1

indicates the time that elapses between the change of the position of the valve (including the

pressurization time of the cylinder) and the beginning of the movement of the piston. Observe how the curves,

which represent the exhaust phase, vary in the two graphs. The value

t

2

indicates the duration time of the

piston stroke. This value is noticeably different in the two graphs because the pressure in the exhaust is released

immediately into the atmospherewithout it going back through the connecting tubes or the control valve.

Note

: it is not advisable to use quick exhaust valves combinedwith 5/3CC valves.

Flow control valves

Part 1

The flow control valves regulate the passage of compressed air through the variation of their internal cross section.

By regulating the flow, it is possible to adjust the speed of the pistons in pneumatic cylinders. The control should

always be performed on the exhausting chamber. Incoming air is only regulated on single acting cylinders.

Unidirectional flow regulator

The connection1 connects to the volume to be regulated and connection2 is the connection directed towards the

main directional valve.

Figure 61

Pos. A

:

the flow of compressed air exiting the chamber enters the regulator via connection 1. The compressed air

encounters lip seal

C

mounted on cartridge

B

and expands to contact with the body of the regulator, creating the

unidirectional function. The compressed air is therefore forced to pass through the reduced cross section created

by the conical part of the adjusting screw

A

and the orifice on the cartridge

B

.

Pos. B

:

the incoming flow of compressed air to the chamber enters the regulator via connection 2. The lip seal

C

gives way, opening the passage and allowing the transit of flow both inside and outside the cartridge

B

. In this

direction the flow is not regulated.

Bidirectional flow regulator

Pos. C

:

the flow of compressed air exiting the chamber enters the regulator via connection 1. In this situation

neither the cartridge

B

or its lip seal are included. The compressed air is forced to pass through the reduced cross

section created by the conical part of the adjustment screw

A

, which bymoving upwards or downwards, changes

the passage cross section between cone and the orifice

D

.

Pos. D

:

the incoming flow of compressed air through connection2 is forced to pass as in the previous case, through

the reduced cross section created by the conical part of the adjustment screw

A

, which through its upwards or

downwardsmovement, changes the passage cross section between the cone and the orifice

D

.

4

125

CAMOZZI

>

VALVES