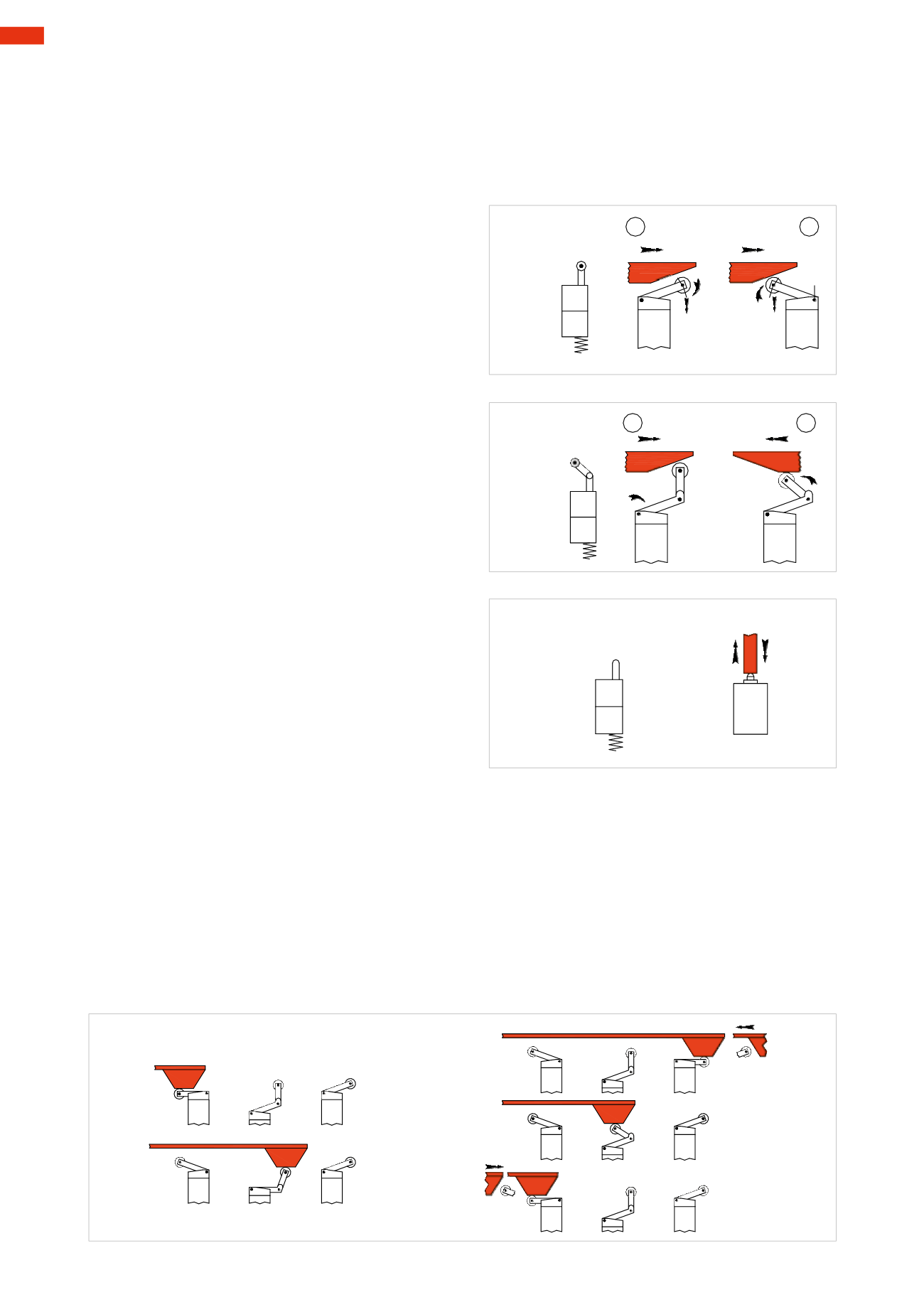

Figure 10

Pos. 1

and

2: roller lever, monostable operation,

spring return.

The drive requires a continuous pressure on the roller

lever and allows the passage of the compressed air if

the valve isNC or its interruption if NO. Such passage

continues for as long as the drive continues.

The roller lever control is used when the object in

motion (cam), which drives the mechanical device

of the limit switch, has a direction of movement

perpendicular to the valve axis. For correct assembly,

the limit switchmust be oriented so that the rotation

of the lever is in the same direction as themovement

of the cam. The return of the valve is set using an

internal spring.

Figure 11

Pos.1

and

2: one-way roller lever control,monostable

operation, spring return.

Corresponds to the roller lever, but the particular

conformation of the drivemakes it unidirectional, the

switching only occurs in one of two directions.

Figure 12

Front control, monostable operation, spring return.

This type of command is used when the object in

motion, which activates themechanical device of the

limit switch, ismoving parallel to the axis of the valve.

At the end of themovement, itmust be ensured that

theobject inmotiondoesnot activate the front control

above themaximum allowed value, given by the sum

of the stroke and the extra-stroke.

ROLLER

OPERATION

LEVER

COMMAND

A

NO!

1

2

Fig. 10

ONE-WAY

OPERATION

ROLLERLEVER

COMMAND

1

2

Fig. 11

FRONT

OPERATION

COMMAND

Fig. 12

Examples of activation

:

Figure 13

A:

with the object in motion (cam) having returned in the starting position, only the first limit switch remains

activated, the others are at rest.

B

: with the cam in the intermediate position, it reaches the limit switch with amechanical device operated by a

unidirectional roller lever and activates it for the entire length of the cam.

This limit switch is at a lower position because themechanical control device of aunidirectional lever roller is larger.

C:

with the cam in the end position, it activates the last limit switchmounted in the direction opposite to the first

cam and keeps it in operation.

D:

during the return stroke, the cam,which is inan intermediateposition, lowers theonly part of the lever inwhich

the limit switch has a one-way function (the knee), thus avoiding switching.

E:

with the cam having returned to the starting position, it only keeps the first limit switch activated.

Mechanical operation of poppet valves

In an automated system human intervention is limited to the start-up or to resolve any emergencies. The progress

of the sequence is determined and controlled by “switch” valves that release a signal when activated. Their

operation - in this case “mechanical”, is determinedby attainment of thedesiredpositions by the bodies inmotion,

for example cylinders.

Some types of mechanical control.

SIMULATIONOFCOMMANDSWITHROLLERDEVICES

A

B

C

D

E

NO!

NO!

Fig. 13

4

96

CAMOZZI

>

VALVES