72

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

FITTINGS BSP

Fittings BSP

2

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

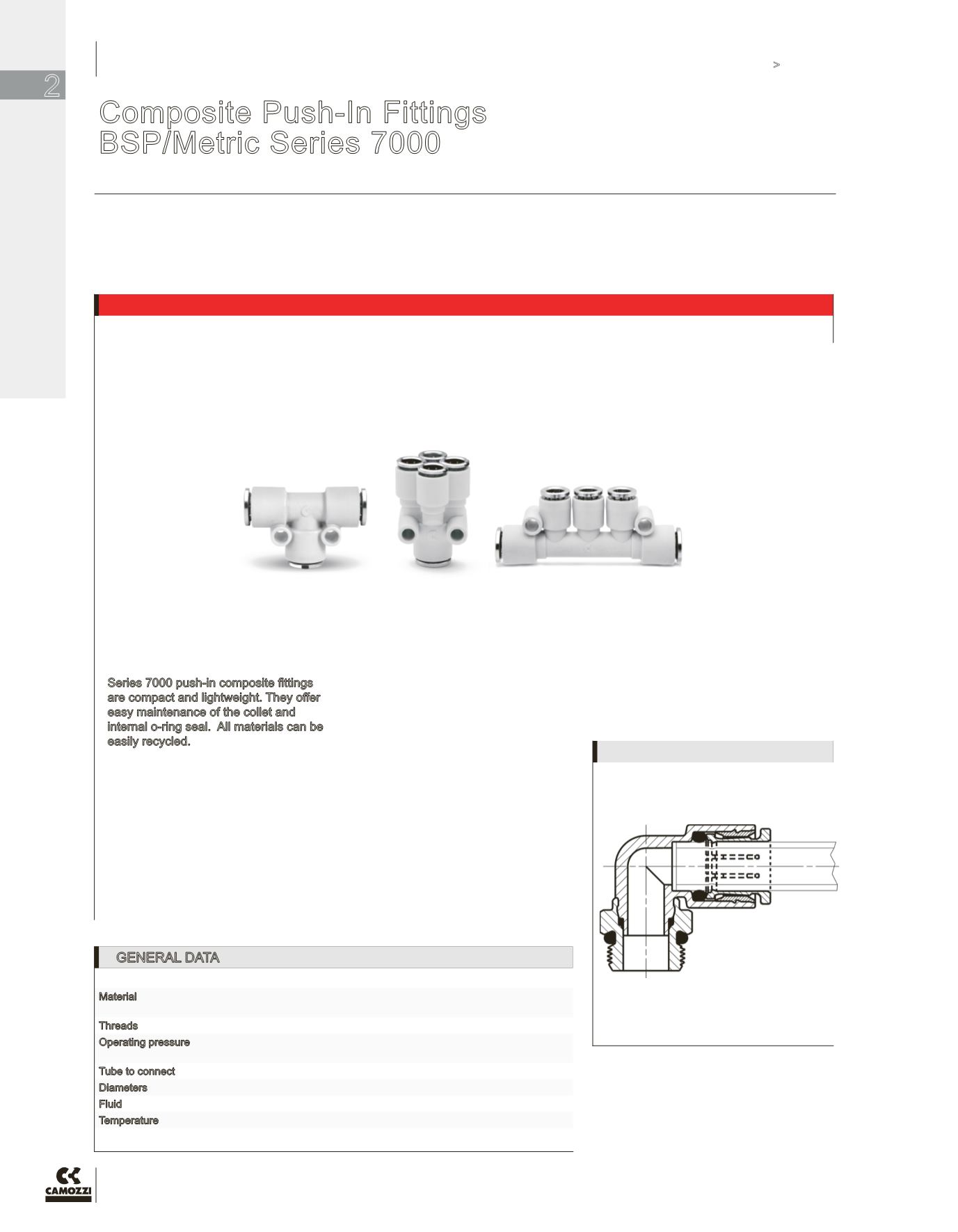

Composite Push-In Fittings

BSP/Metric Series 7000

Tube Diameter OD: 4, 6, 8, 10, 12, 16 mm

Thread Type: metric (M5, M7), BSP (G1/8, G1/4, G3/8, G1/2, G3/4),

with Spot-Face O-ring Seal

GENERAL DATA

Material

body: technopolymer (glass reinforced Nylon 66 resin); insert: brass, collet:

nickel-plated brass; seals: NBR

Threads

GAS cylindrical ISO-228 (BSP)

Operating pressure min. - 0,9 bar, max. 16 bar (28” Hg vacuum to 250 psi) (see data for tubing

used)

Tube to connect

Nylon 6, 11 or 12, polyethylene, PU, Hytrel Polyester

Diameters

ø 4 - 6 - 8 - 10 - 12 - 16 mm

Fluid

compressed air (for other types of fluids, contact our engineers)

Temperature

-20° - 60°C (-4 F to 175 F) ( see data for tubing used)

Fitting with connecting tube

Series 7000 push-in composite fittings

are compact and lightweight. They offer

easy maintenance of the collet and

internal o-ring seal. All materials can be

easily recycled.

The nickel-plated brass collet

maintains the same technical

characteristics as the other

nickel-plated brass fittings.

It provides a uniform grip

around the entire surface

of the plastic tube. This

ensures high reliability and

long service life, especially

after several connections and

disconnections of the tubing.

Series 7000 composite fittings

are especially suited to

lightweight applications and

compact assembly locations,

typical in the automation

markets.