73

The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

FITTINGS BSP

Fittings BSP

2

NORTH AMERICAN FITTINGS & FLOW CONTROL VALVE CATALOG

>

Release 8.6

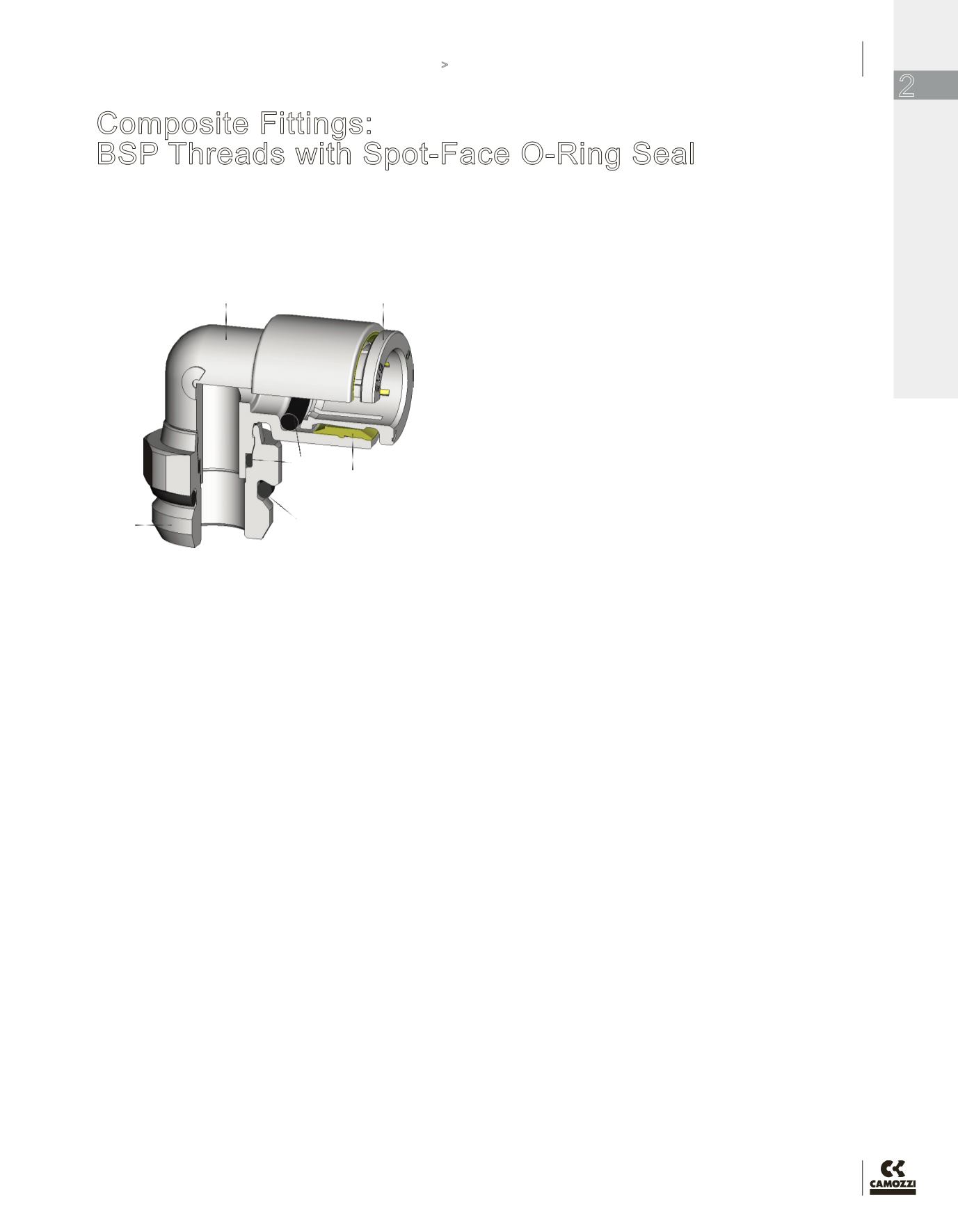

Composite Fittings:

BSP Threads with Spot-Face O-Ring Seal

The technical solution:

Camozzi has maintained the technically advanced and world-

renowned collet solution by further optimizing the dimensions and the design from

Series 6000 Fittings and Flow Control Valves.

Durable Metal Collet:

Nickel-Plated brass collet provides superior

resistance to shock, wear and fatigue compared to inferior plastic

collets. Proven metal design offers a higher holding force with easier

tube release that won’t scratch tubing like plastic “bite-ring” designs.

Tube OD size is stamped on collet face.

Composite Body:

Glass-fiber reinforced, thermoplastic material

is incredibly strong and lightweight with improved resistance to

UV exposure, abrasion and other chemical substances. Molded

composite material allows for integral mounting holes and a broader

range of complex shapes.

Spot-Face O-Ring Thread Seal Design:

Reusable Buna-N seal

reduces assembly time by up to 45% and eliminates exposed

threads, making it ideal for food processing, robotics, packaging

& manifold assemblies. Eliminates risk of pneumatic system

contamination from sealants’ residue.

Features

Collet

• Nickel-Plated, All-metal Collet and Release ring

• Brass insert for collet support and tube grip strength

• Collet design offers greater grip strength under higher

pressure or tubing tension

• Collet release mechanism based on relaxed slope of grip

teeth, as opposed to disengaging “bite-rings” from partially

cut tubes

• Removable Collet and tube o-rings

Body

• Glass-fiber reinforced, thermoplastic compact injection-

molded body

• All-Metal, Nickel-Plated Threads

• Standard Buna-N or Specialized O-ring choices for High-

Temp, Low-Temp, Special Fluids, Food-Grade compatibility

• Broad Range of shapes and configurations

• Crimp design on Swivels maintains Full ID Flow path

• Swivels offer Mechanical crimping lock based on brass

design

Thread Design

• Multiple Thread sealant systems: BSP/O-Ring Spot Face

• Full ID Flow for Swivels with high relief on larger sizes

• Swivels supported on two surfaces for stability and support of

captured swivel o-ring seal

Benefits

Collet

• Won’t break like plastic release rings, More Durable design

• Brass insert maintains collet stability, tube grip strength and

consistent tube-release performance

• Higher holding force, with easier release

• Won’t scratch tubes like “bite-ring” designs

• Less chance of micro-leakage and bubble-leaks over time due to

damaged tubing

• Higher pressures actually offer greater grip-strength with high-

pressure Nylon tubing

• OD Tube Size stamped on Collet face

Body

• Thermoplastic Nylon composite more resistant to UV exposure

• Better resistance to stress-cracking, abrasion, solvents,

detergents & hydrocarbons

• 15% Reduction in overall Body size, (24% in Assembly height /

8% in Tube Radius), compared to recently reduced-size Brass

line

Spot-Face O-Ring Thread Design

• Reduced assembly time without taping of threads

• Re-usable seal design, with no exposed threads

• FDA/NSF approved materials

• Simplified manifold circuits with broader variety of fitting

combinations and shapes to select

• Lighter weight for End-of-Arm tooling & Robotic handling

• Compact design reduces overall dimensions for valve

assemblies, packaging applications and control cabinets

Metal Collet

Metal Collet

Insert

Spot-Face Seal

Composite Body

Metal

Thread

O-Ring

Seal