Nominal flow rate

The following factorsmust be consideredwhen selecting components:

• The distribution linemust be dimensioned to fulfil the requirements of the system to be served.

• The larger the flow section, the greater the possible flow rate.

• Any request of air always creates a pressure drop.

• Increasing the request of air, with the same flow section, increases the drop in pressure.

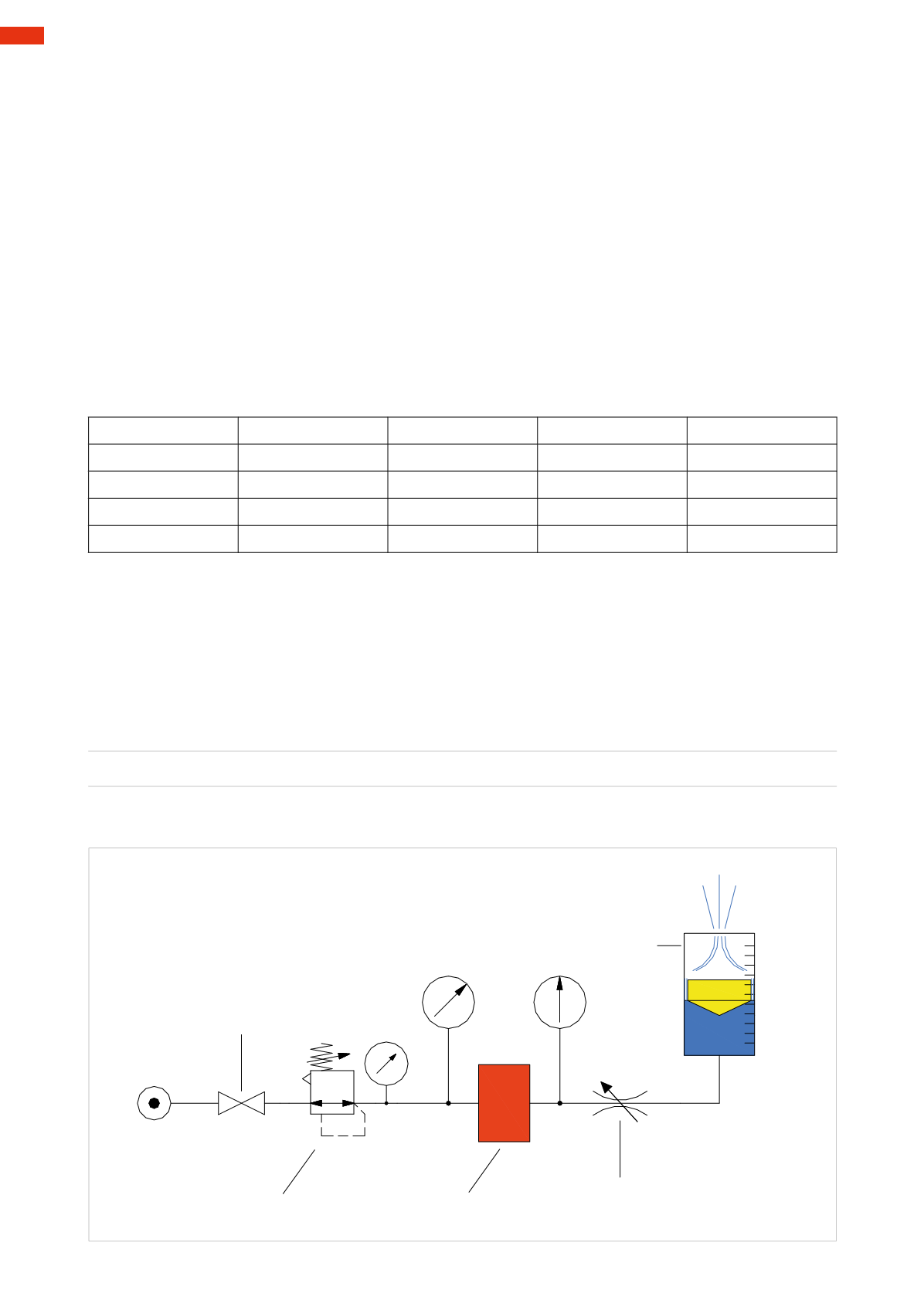

Figure 56

Similar to the distribution line, valves must also be sized correctly in order to be able to provide a quantity of

compressed air sufficient to that required by the equipment in use. The selection should not be based on the size

of the connection, but in reference to the flow rate indicated by the technical data of the product.

In order to have one size as reference, the ISOStandards (International StandardOrganization) prescribes the use

of the term

Nominal Flow

rate as that which every valve effectively supplies perminute in defined test conditions:

• Regulated pressure 6

bar

• Ambient temperature 20

°C

• Pressure drop (

∆

p) 1

bar

Conversion table of themost common units of measurement.

1

kv

Kv

0,06

C

v

0,069

f

0,057

Q

n

67

1

Kv

C

v

1,179

f

1,000

Q

n

1149

kv

16,67

1

C

v

f

0,83

Q

n

962

kv

14,42

Kv

0,85

1

f

Q

n

1159

kv

1,85

Kv

0,97

C

v

1,205

1

Q

n

kv

0,015

Kv

0,0009

C

v

0,001

f

0,0009

kv

= flow of water with

∆

p

= 1

bar

at 20°C [

l/min

]

Kv

= flow of water with

∆

p

= 1

ba

r at temperature ranging from 5°÷40°

[

m³/hour

]

C

v

= Flow of water with

∆

p

= 1

PSI

[

USGallons/min

]

f

= as above but expressed in

Imperial Gallons

Q

n

= nominal flow ratewith inlet pressure 6

bar

and

∆

p

=1

bar

at temperature of 20

°C

[

Nl/min

]

Example

: conversion of a flow rate of 17

kv

into

Qn

:

1

kv

=67

Q

n

[Nl / min]

17

kv

=17 * 67

Q

n

A flow rate of 17

kv

corresponds to a

Q

n

of 1133

Nl/min

.

Pressure regulator

Tested valve

Tapor Ball valve

Flow regulator

Flowmeter

Nl/min.

Fig. 56

4

120

CAMOZZI

>

VALVES