1

2

3

4

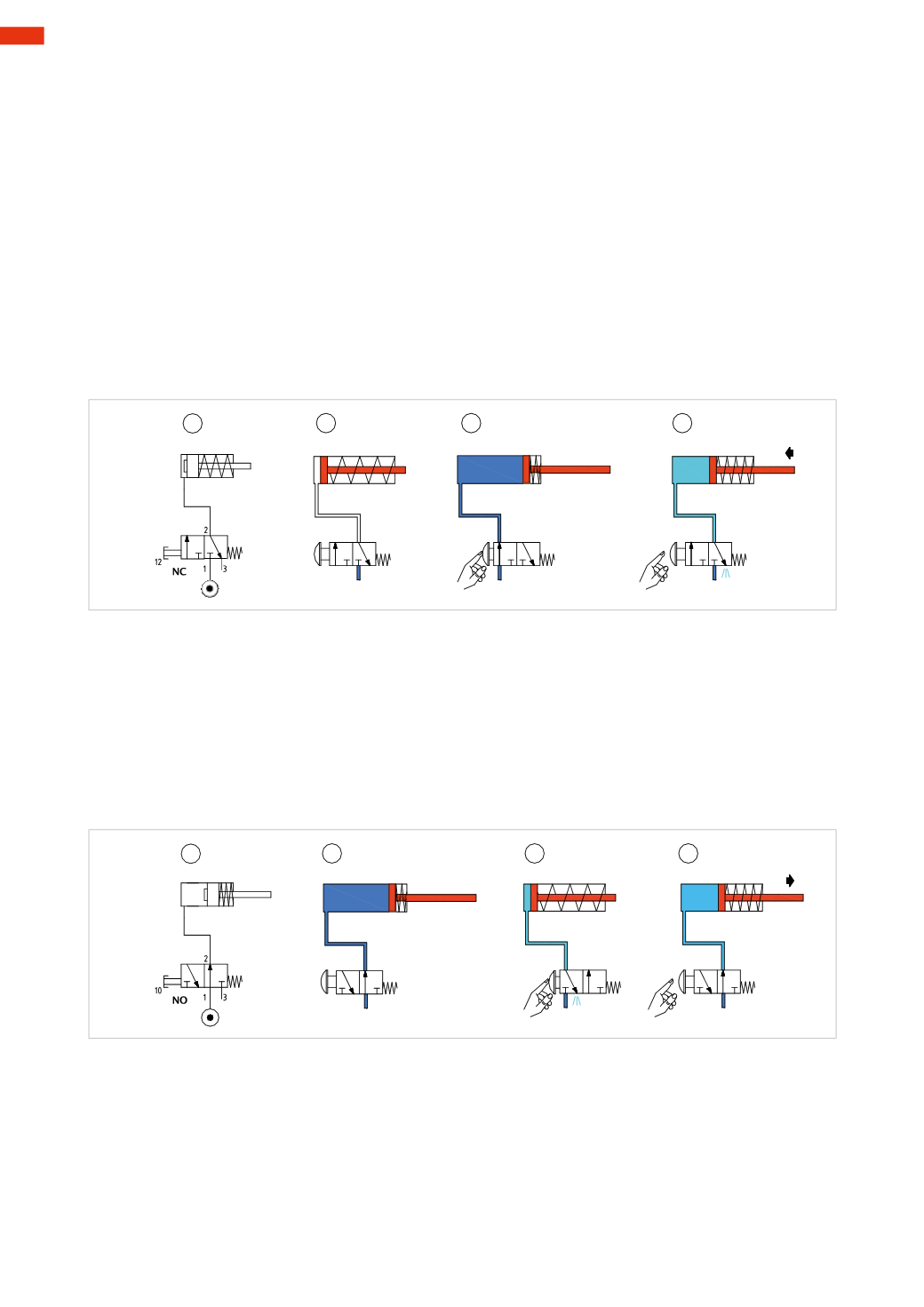

Fig. 12

Elementary circuits

The term elementary circuit refers to “basic” circuits such as those for the control of a single cylinder.

Control of a single-acting cylinder

When pressurizing only one chamber of a cylinder, a 3/2-way

(3-ways 2-position)

valve is used. The selection of

theNC or NO version of this valve depends on the selected position of the cylinder at the beginning of the cycle.

Figure 12

Pos. 1:

with an NC valve, there is no compressed air exiting outlet 2 (while at rest position), the piston is in the

negative or retracted position due to the effect of themechanical spring.

Pos. 2:

the compressed air present at inlet 1 cannot pass because the valve is NC. Inlet 1 is closed and outlet 2

is connected to exhaust port 3 (valve at rest position).

Pos. 3:

when the operator presses and holds down the push button, the compressed air passes through the valve

from inlet 1 to outlet 2 (actuated valve). This air arrives to the cylinder pressurizing the positive chamber.

The pistonmoves forward to its extended position.

Pos. 4:

when the button is released, the valve returns to its rest position, the inlet 1 closes and outlet 2 connects

with exhaust 3 in order to allow the compressed air in the cylinder chamber to exhaust into the atmosphere,

allowing the piston to return to its original positionwith the help of its spring.

Figure 13

Pos. 1:

withanNO valve, compressedair is exiting fromoutlet2 (whileat rest position), thepiston rod/piston reaches

the positive end position due to the thrust of the compressed air which compresses the spring inside the cylinder.

Pos. 2:

the compressed air passes through the valve from inlet 1 to outlet 2 (valve at rest position). This air reaches

the cylinder and pressurizes the positive chamber, moving the piston rod/piston forward to its extended position.

Pos. 3:

when the operator presses and holds down the push button, the passage between inlet 1 and outlet 2 is

interrupted. The compressed air present in the cylinder chamber passes outlet 2 and discharges through exhaust

3. The piston rod/piston retreats due to the effect of themechanical spring.

Pos. 4:

when thepushbutton is released, the valve returns to its rest position, inlet 1opens allowing the compressed

air through outlet 2, enabling the return of the piston rod/piston to the positive end position.

1

2

3

4

Fig. 13

Control of a double-acting cylinder

Double-acting cylinders (DA) require air to flow in two directions to achieve both positive and negative strokes. For

this reason, the distribution valvemust have two independent outlets, i.e., a 5/2-way

(5-ways 2 position)

valve.

Figure 14

Monostable valve, directly operated

Pos. 1:

the 5/2-waymonostable valve in rest position has outlet 2 under pressure. The position of the piston rod/

piston of the double-acting cylinder, which is controlled by the valve, is dependent uponwhich chamber the active

outlet 2 is connected to.

Pos. 2:

the valve is at rest, the compressed air is connected to inlet 1 through outlet 2 and supplies the negative

chamber of the cylinder, holding the piston rod/piston against the rear end cap.

5

138

CAMOZZI

>

CIRCUIT TECHNIQUE