CYLINDERS

Piston rodmountings

The connection of the cylinder body and the connection of the piston rodwhenmounted on the object to be driven

must be done in such way that anymisalignment between the axis of the piston rod, body and the driven object

is eliminated. Before putting an installation into operation, it is advisable to check the alignment of the loadwith

the piston rod from its retracted to extended position. An incorrect alignment will generate a radial Force on the

piston rodwhich eventuallywill cause deformation of the guide bushwhich consequently leads to prematurewear

of the tightening seals on the piston rod and piston.

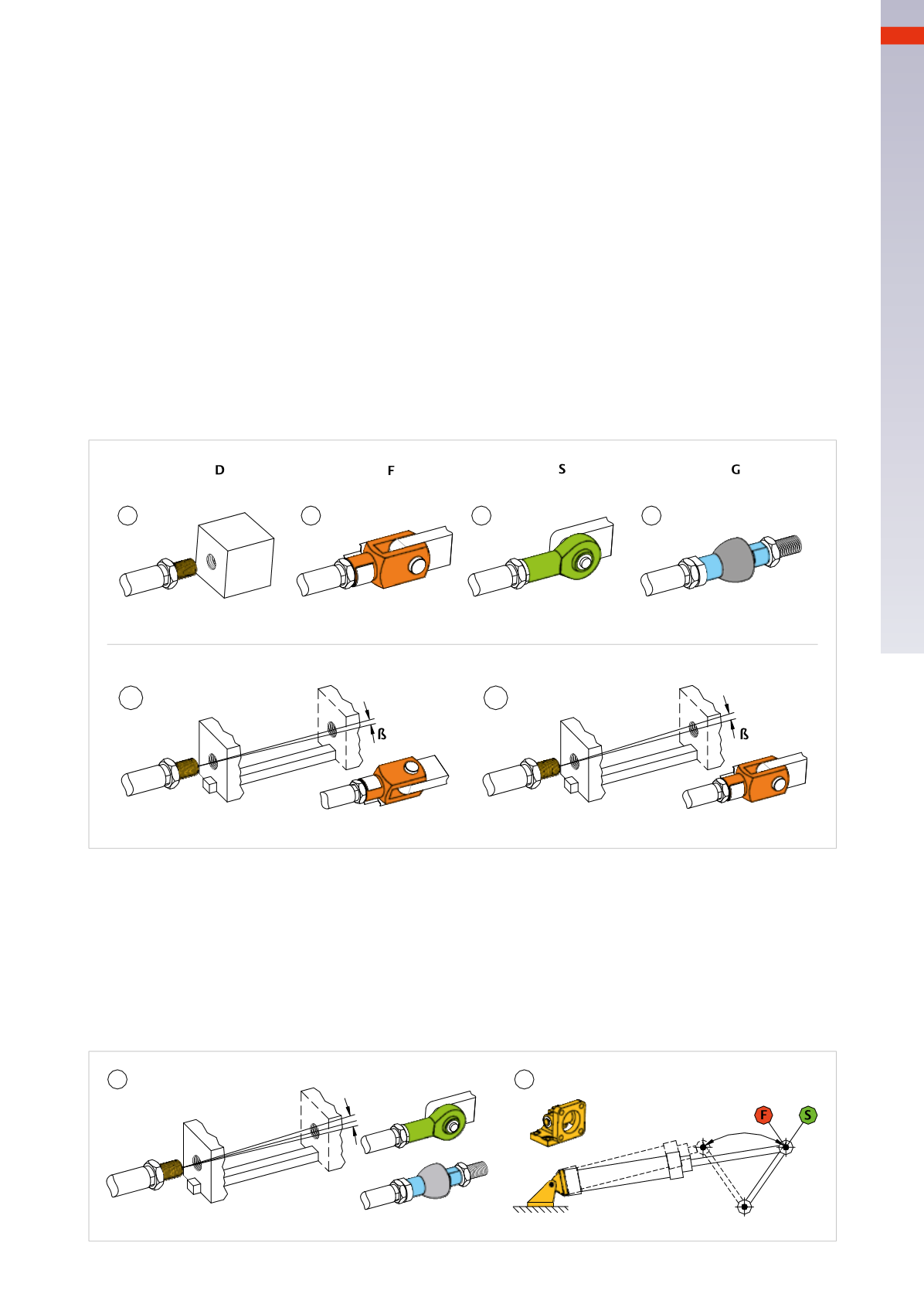

Figure 14

Pos. 1

: the object tobemoved is not bound toany guides and the rod canbedirectly secured to themoving object.

This fixture is defined as

direct

.

Pos. 2

: fastening by means of a

rod fork

. Provides liberty of movement in one axis, hence does not provoke any

radial Force due to themotion of the attached object in that axis.

Pos. 2a

: the moving load travels along an axis parallel to the cylinder centre line with a lateral deviation in the

horizontal plane of angle

β

. In this situation the rod exerts a radial load on the guide bush, by inserting a rod fork

you compensate for that angle and substantially reduce the radial load.

Pos. 2b

: the loadmovesupwards of angle

β

and the piston rod is forced towork on the upper part of bushing: also

in this case the fork, with a different orientation, is able to compensate themisalignment.

Pos. 3

: securedwith

swivel ball joint

.

Pos. 4

: fastening bymeans of a

piston rod socket joint

.

1

2

3

4

2b

2a

Direct

Rod clevis

Swivel ball joint

Piston rod

socket joint

Fig. 14

Figure 15

Pos. 5

: if the misalignment occurs in the two planes, the bush will be subject to wear in these two planes.

By inserting a swivel ball joint

S

or a piston rod socket joint

G

it is possible to compensate for that misalignment.

Pos. 6

: the angularmovement is always occurring on the same plane.With this assumption, andwith the evident

need to support the cylinder with a bracket that allows the cylinder to oscillate, the piston rod can be connected

to the lever with a rod fork

F

. If there’s any doubt about themovement remaining on the same plane, a swivel ball

joint

S

should be used instead. With this solution it is advisable to check the radial load generated by the weight

of the cylinder. When the rod is in external position this load is acting on the bronze bushing, provoking damage.

In particular, with long strokes it is preferable to use a cylinder mountingwith a center trunnion.

5

6

Fig. 15

3

65

CAMOZZI

>

CYLINDERS