CIRCUIT TECHNIQUE

1

2

3

4

5

6

_

+

+

B

A_

_

_

+

+

_

_

B

2 1

+

B

+

_A

_

A_

+

+

B

2 1

3

+

B

+

A_

_

_A

+

+

1

2 1

3

2

1

cycle

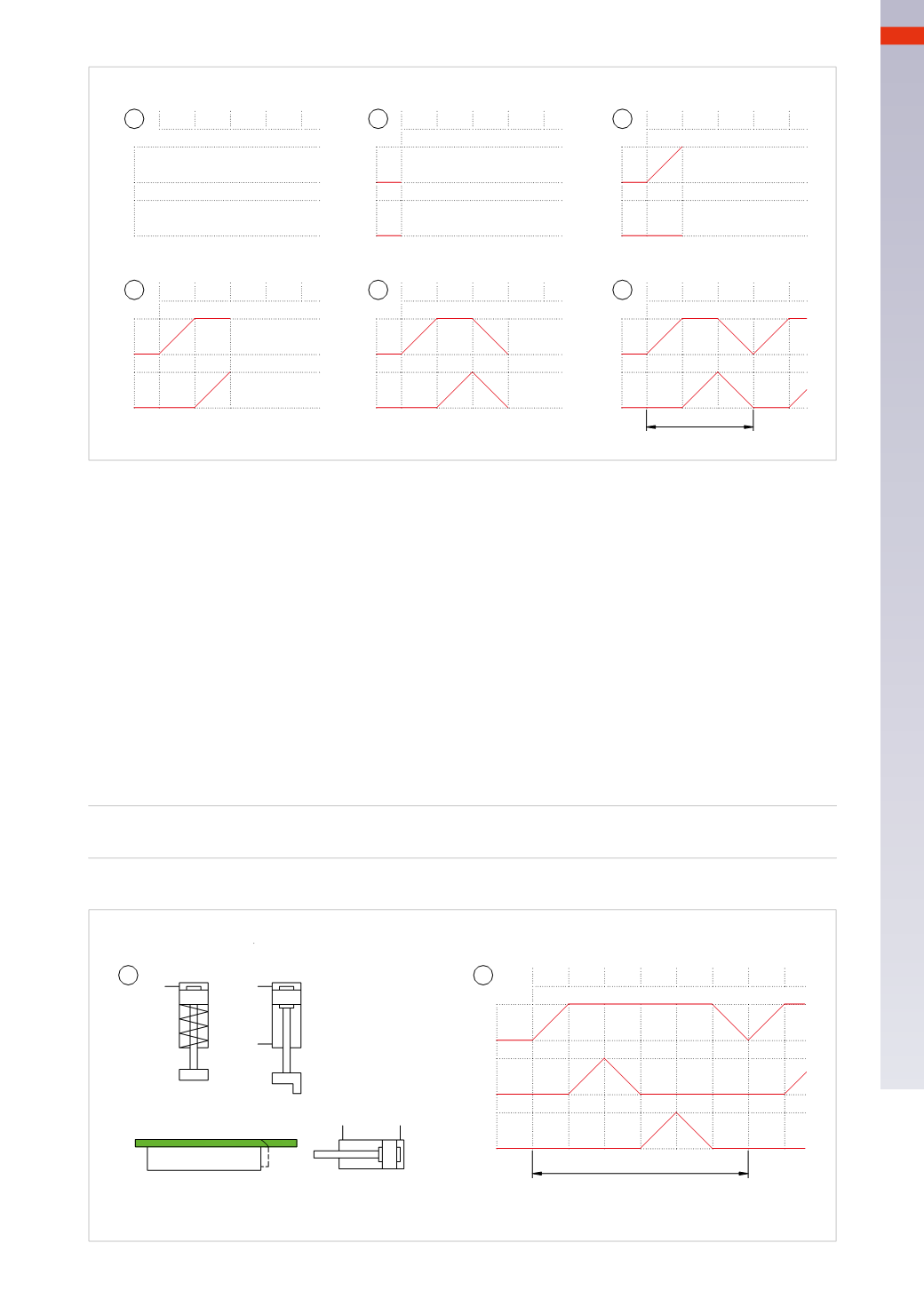

Fig. 24

Flow diagramwith various examples:

Figure 25

Pos. 1

: manually positionedmetal sheets are to be bent and have a hole punched on the short end. Devices with

cylinders that perform certain operations in successive phases are required:

Phase 1

cylinder

A

extends and clamps the sheet for thewhole duration of the operation

A+

Phase 2

cylinder

B

, if the component is blocked it can perform the bending operation

B+

Phase 3

cylinder

B

clears theworking area to allow the next movement

B –

Phase 4

cylinder

C

performs the hole punching

C+

Phase 5

cylinder

C

clears theworking area

C –

Phase 6

cylinder

A

releases the sheet which can now be removed

A –

In this case, no twomovements are simultaneous,

they are all sequential.

Representation of the sequence in literal form:

A+ / B+ / B – / C+ / C – / A –

1

2

3

4

5

6

Pos. 2

: graphical representation.

1

2

A

_

+

+

_

_

cycle

2

+

1

3

5 4

6 1 2

A

B

C

C

B

Fig. 25

5

145

CAMOZZI

>

CIRCUIT TECHNIQUE