CYLINDERS

Constructive characteristics

There are different types of pneumatic cylinders, themost common are:

• with rolled end caps;

• end caps attached to the tube bymeans of tie rods;

• end caps attached at the profile fixedwith screws;

• end caps integrated into the cylinder body and fixed in positionwith seeger rings;

• threaded end caps.

On the end caps, points for the connection of the attaching elements of the cylinder are located.

Among the various cylinders, there are cylinder ranges that complywith the International Standards as regards the

overall dimensions and spacing of the fixing holes, for example:

DIN/ISO 6432

for cylinders with diameters from8 to 25

mm

ISO15552

(which has replacedDIN/ISO6431 / VDMA24562) for cylinders with diameters from32 to 320

mm

ISO21287 for compact cylinders with diameters from 20 to 100

mm

The range of applications vary greatly thereforematerials and treatments can be customized.

•

Cylinder end caps

: normally they’remade of aluminium. In the presence of salt spray (marine environments) or

in hostile environments they can be treated, varnished or constructedwith other materials.

•

Piston rod

: generallymade of stainless steel.

•

Tube/barrel or profile

: usually made of aluminium, which has been anodized. This treatment significantly

reduces theeffect of scale. Another commonmaterial for the tube/barrel is steel (for cylinders of bigger dimensions).

•

Seals

: the shape and thematerial used are of considerable importance; as well as ensuring the resistance, they

must meet the following requirements:

- chemical resistance to lubricants;

- low friction andwithout the tendency towards sticking;

- resistance towear and external agents.

They can bemade of differentmaterials e.g. NBR, HNBR, polyurethane, FKM etc..

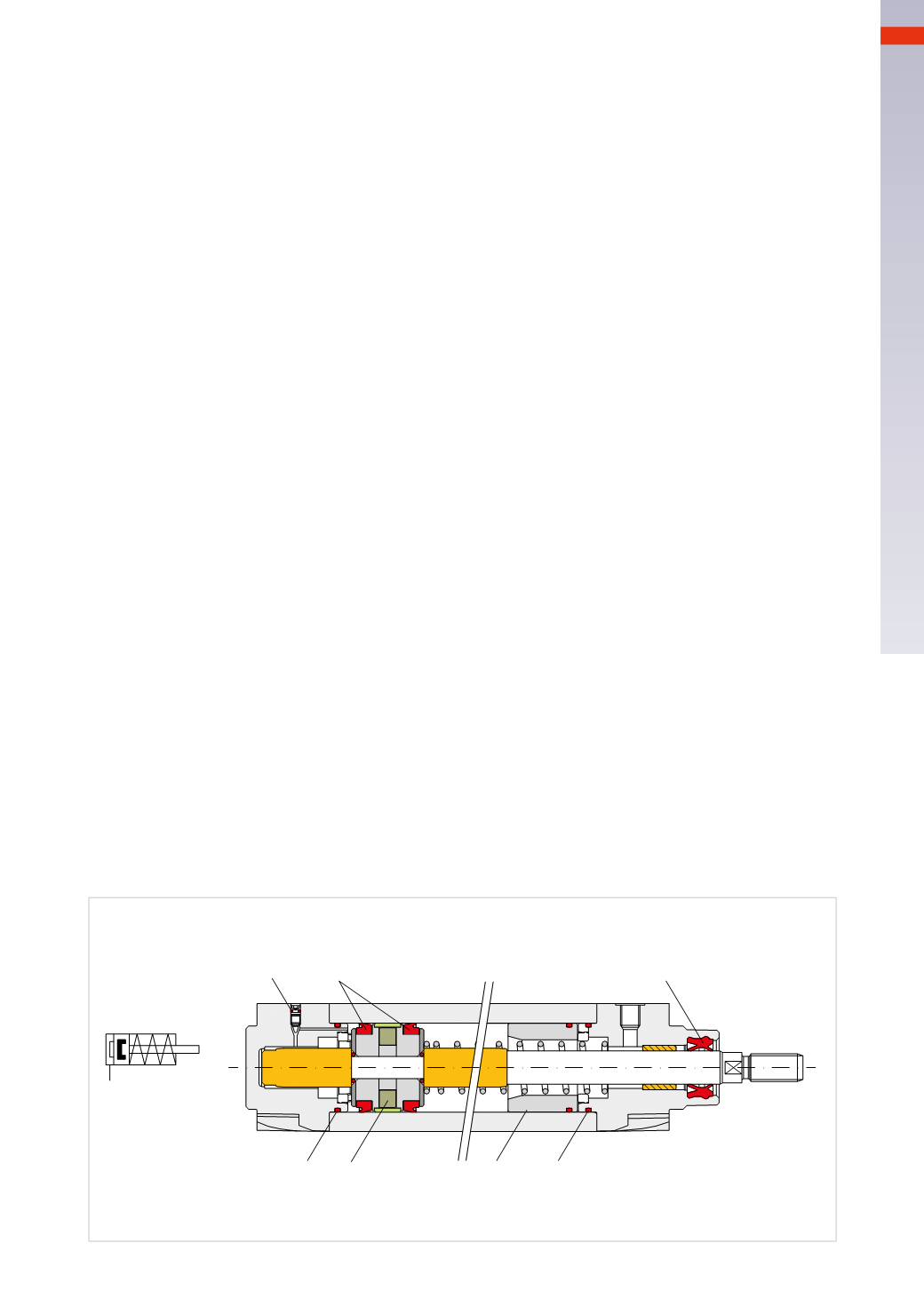

Seals are used:

- on the piston: generally there are two lip seals

A

;

- on the piston rod: this exerts a dual function of sealing and cleaning/scraping

B

;

- on the cushioning chambers

C

;

- on the end caps and the adjustment screws of the cushioning

F

and

D

.

The cylindersmay bemagnetic, enabling the detection of the position of the piston.

Themagnet

E

, which has awell-definedmagnetic field, is detected by sensors above the cylinder tube.

Normally the cylinders are:

Figure 8

Single acting (S/A)

: can bewith the return spring either in thrust- or tractionmode.

Tractionmode

: the return spring, guided by the piston rod, keeps the piston rod/piston in negative end position.

The hole on the front-end cap serves tomaintain the negative chamber in connectionwith the atmosphere.

Thrust mode

: the return spring keeps the piston rod/piston in the positive end position. The hole on the rear end

cap serves tomaintain the positive chamber in connectionwith the atmosphere. The spacer

G

allows the correct

repositioning of the return spring.

A

B

E D

D

G

F

MAGNETIC

SINGLE-ACTING

CYLINDER

Fig. 8

3

59

CAMOZZI

>

CYLINDERS