The company reserves the right to vary models and dimensions without notice.

These products are designed for industrial applications and are not suitable for sale to the general public.

STAINLESS STELL CYLINDERS

Stainless Steel Cylinders

3

NORTH AMERICAN CYLINDER & ACTUATOR CATALOG

>

Release 8.5

186

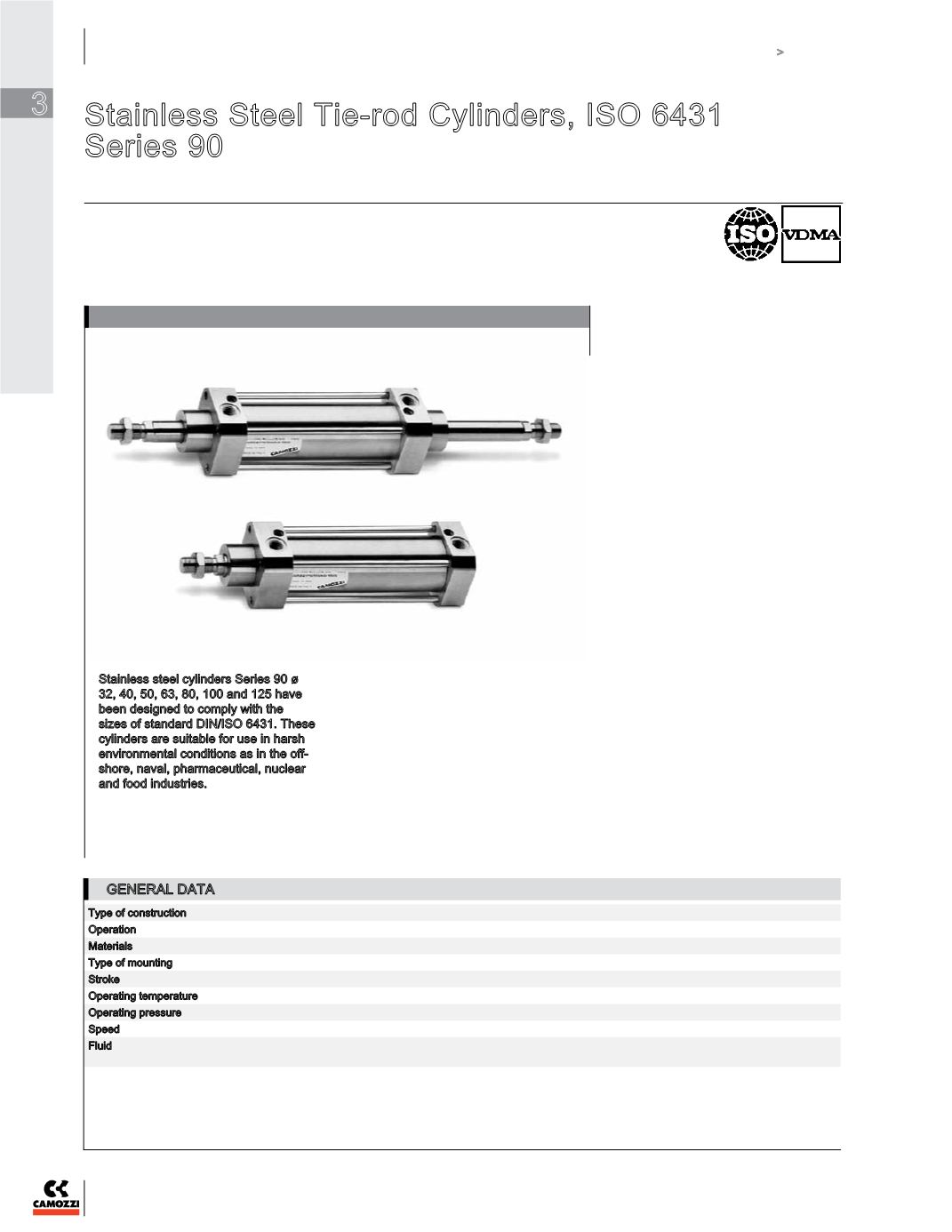

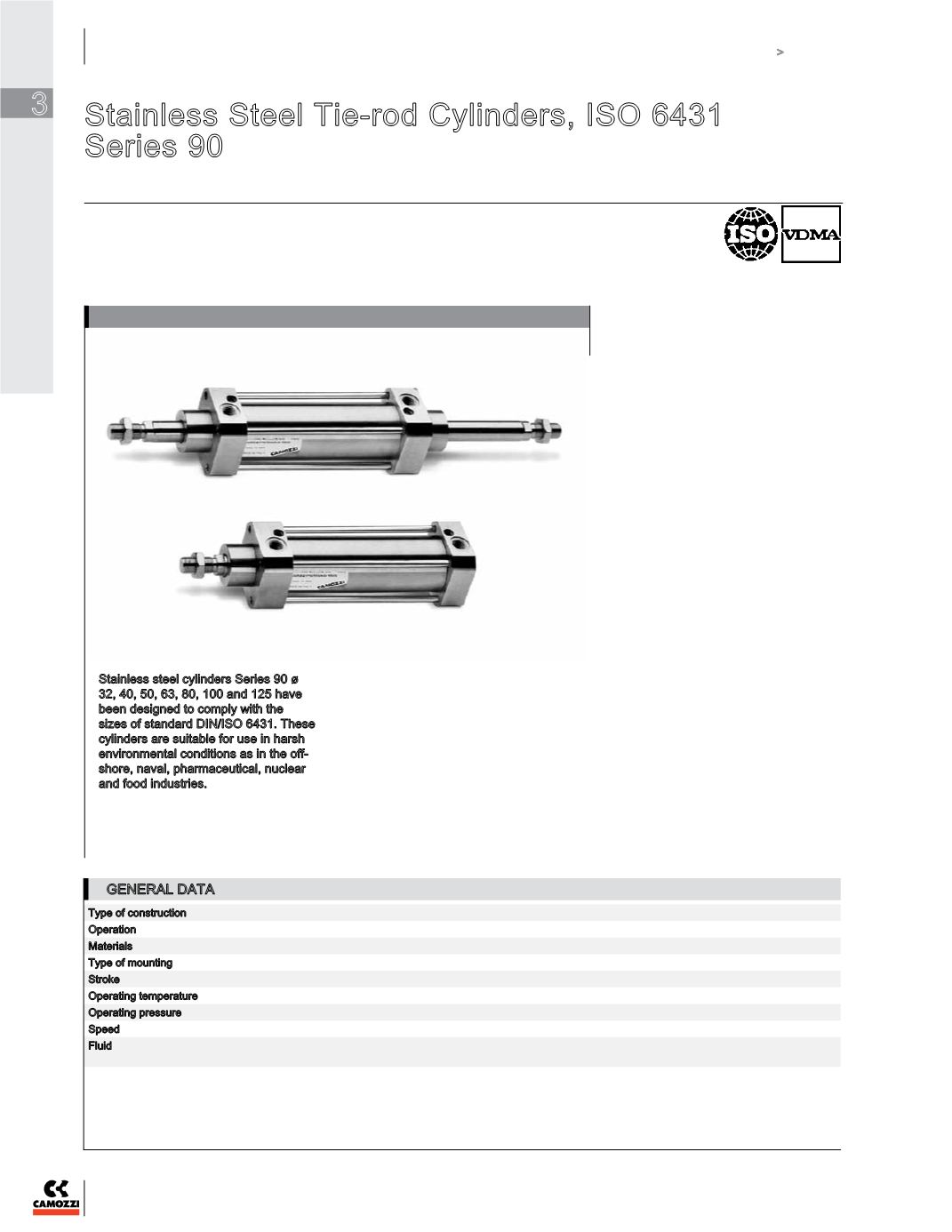

Stainless Steel Tie-rod Cylinders, ISO 6431

Series 90

Single or double-acting, cushioned, magnetic (DIN/ISO 6431)

ø32, 40, 50, 63, 80, 100 and 125

Stainless steel cylinders Series 90 ø

32, 40, 50, 63, 80, 100

and 125 have

been designed to comply with the

sizes of standard DIN/ISO 6431. These

cylinders are suitable for use in harsh

environmental conditions as in the off-

shore, naval, pharmaceutical, nuclear

and food industries.

A permanent magnet is mounted on the

piston in these cylinders. The position

of the cylinder is obtained by the

magnetic proximity switches mounted

on the cylinder. This series of cylinders

is normally equipped with adjustable

end-stroke cushioning. In addition these

cylinders are equipped with a mechanical

cushioning in order to make the impact

of the piston less noisy as it reaches the

end of the stroke.

GENERAL DATA

»

»

DIN/ISO 6431

»

»

Clean design

»

»

Stainless steel AISI 316

Type of construction with tie-rods

Operation

single-acting or double-acting

Materials

end block, tube, tie-rods and rod = stainless steel AISI 316 (SS 2343); seals = NBR

Type of mounting

front and rear flange - feet front and rear bracket - swivel combination

Stroke

standard (see table) / min-max: all bores 25-800 mm

Operating temperature 0°C – 80°C (with dry air - 20°C) (32 - 176°F, with dry air -4°F)

Operating pressure

1 – 10

bar, (14 - 145 psi)

Speed

10 – 1000

mm/sec (no load)

Fluid

clean air, without lubrication.

If lubricated air is used, it is recommended to use oil ISOVG32. Once applied, lubrication should never be interrupted.